Assembly of High-Strength Structural Bolting for Preloading According to UNI EN ISO 14399: Technical Analysis and Applications

Introduction

High-strength structural bolting for preloading is essential to ensure the safety and stability of steel structures. The UNI EN ISO 14399 standard defines the requirements for these bolting assemblies, which are used in structural connections subject to dynamic loads and extreme conditions. Thanks to their high strength and preload capability, these components are crucial in applications where durability and safety are of primary importance, such as bridges, skyscrapers, and industrial structures.

Characteristics of High-Strength Structural Bolting

Material and Heat Treatments

Description: The bolts are generally made of high-strength steel, subjected to specific heat treatments to enhance mechanical properties such as hardness and tensile strength.

Applications: These bolts are used in structures where high resistance is required to withstand dynamic and cyclic loads.

Preload Capacity

Description: Preload capacity is a key feature of these bolts. The applied preload generates a clamping force that prevents slippage of the connections and increases fatigue resistance.

Applications: Essential in connections subject to variable loads and vibrations, such as in bridge structures and large steel constructions.

Corrosion Resistance

Description: High-strength structural bolting must be treated to resist corrosion, often through protective coatings such as hot-dip galvanization.

Applications: Necessary in aggressive environments, such as marine constructions or industrial areas, where corrosion could compromise structural integrity.

Compliance with UNI EN ISO 14399

Description: The standard specifies design, manufacturing, and testing requirements for high-strength structural bolting, ensuring that each component is suitable for its intended use.

Applications: Used in civil and infrastructure engineering projects requiring compliance with international standards for safety and quality.

Table: Mechanical Properties of Structural Bolting According to UNI EN ISO 14399

| Property | Typical Value | Applications |

|---|---|---|

| Tensile strength | ≥ 800 MPa | High-strength structural connections |

| Preload capacity | 70% - 90% of the minimum tensile strength | Prevention of slippage and increased fatigue resistance |

| Surface hardness | ≥ 300 HV | Increased wear and fatigue resistance |

| Corrosion resistance | ≥ 720 hours (salt spray test) | Aggressive and marine environments |

Applications of High-Strength Structural Bolting

Bridge Construction

Example: Bolting used in the joints of beams and pillars in road and railway bridges, where connections must withstand high cyclic loads and resist adverse environmental conditions.

Advantages: Increases structural durability and reduces the need for frequent maintenance.

Large Steel Structures

Example: Use in skyscrapers and large industrial buildings, where stability and safety of structural connections under heavy loads are critical.

Advantages: Provides high tensile and shear strength, ensuring structural safety.

Industrial Infrastructures

Example: Bolting for load-bearing structures in refineries, power plants, and other critical industrial infrastructures.

Advantages: Withstands dynamic loads, vibrations, and harsh operating conditions while maintaining structural safety and integrity.

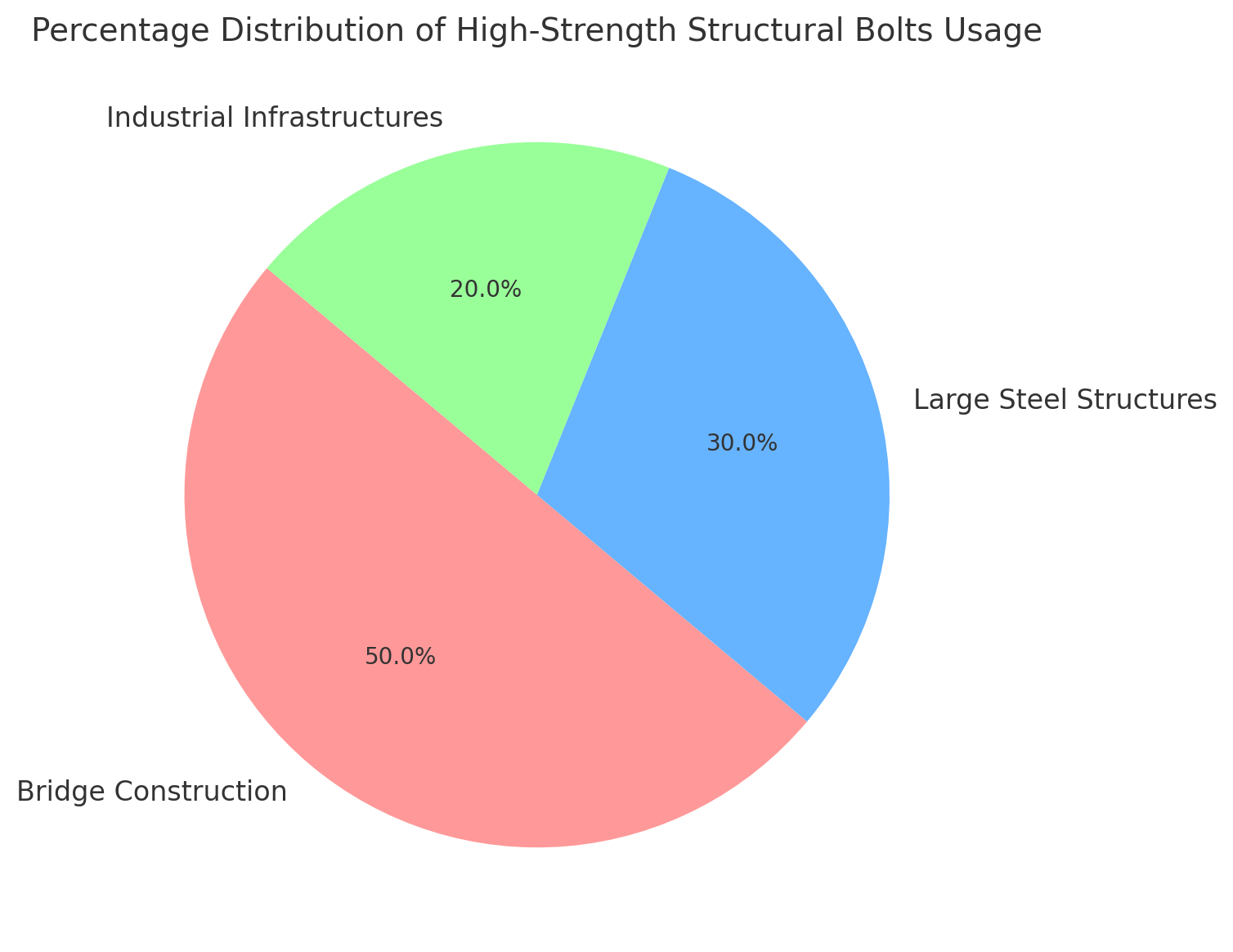

Chart: Distribution of High-Strength Structural Bolting Applications

Below is a chart showing the percentage distribution of common applications for high-strength structural bolting:

This chart highlights how high-strength structural bolting is widely used in bridge construction, large steel structures, and industrial infrastructures, where traceability and strict compliance are essential.

Advantages and Challenges in Using High-Strength Structural Bolting

Advantages

- High Strength and Durability: These bolts are designed to withstand extreme loads and harsh environmental conditions, ensuring long service life.

- Reduced Risk of Slippage: The applied preload prevents slippage of connections, enhancing structural stability.

- Compliance with International Standards: Bolting compliant with UNI EN ISO 14399 ensures that structures meet the highest safety and quality requirements.

Challenges

- Production and Installation Costs: Manufacturing high-strength bolting and ensuring proper installation can involve significant costs, especially for large-scale projects.

- Need for Specialized Labor: Proper installation requires skilled personnel, increasing labor costs.

- Maintenance and Monitoring: Although high-strength bolts reduce maintenance needs, periodic inspections are still necessary to ensure long-term safety.

Commercial Conclusion

High-strength structural bolting for preloading compliant with UNI EN ISO 14399 is a critical component for the safety and durability of steel structures. Although production and installation costs may be high, the benefits in terms of safety, resistance, and compliance with international standards far outweigh the drawbacks. For companies operating in high-criticality sectors, adopting this bolting not only improves the quality of structures but also represents a significant competitive advantage, ensuring compliance with regulations and reducing the risk of structural failures.