Assembly of Non-Preloaded Structural Bolts According to UNI EN 15048: Technical Analysis and Applications

Introduction

Non-preloaded structural bolts are a fundamental component in steel constructions, where connections must ensure safety and stability without the need for a specific preload. The UNI EN 15048 standard defines the requirements for these bolt assemblies, designed for use in structural connections subject to static loads or limited dynamic loads. These components are essential in many engineering applications, where ease of installation, adequate strength, and compliance with standards are key requirements.

Characteristics of Non-Preloaded Structural Bolts

Material and Mechanical Properties

Description: Non-preloaded bolts are made of carbon steel or alloy steel, with mechanical properties suitable for withstanding applied static loads.

Applications: Used in structures where preload is not required to ensure safety, such as commercial buildings, industrial warehouses, and light infrastructures.

Absence of Preload

Description: Unlike high-strength bolts, these bolts do not require a specific preload. They are designed to withstand static loads without the risk of slippage in joints.

Applications: Ideal for structural connections where dynamic stresses are limited or absent.

Corrosion Resistance

Description: These bolts can be treated with protective coatings, such as galvanization, to improve corrosion resistance, especially in outdoor environments.

Applications: Necessary for applications exposed to atmospheric agents, to ensure long-term durability.

Compliance with UNI EN 15048 Standard

Description: The standard specifies the design, production, and testing requirements for non-preloaded structural bolts, ensuring that each component is suitable for its intended use.

Applications: Used in construction projects requiring compliance with European safety and quality standards.

Table of Mechanical Properties of Structural Bolts According to UNI EN 15048

| Property | Typical Value | Applications |

|---|---|---|

| Tensile Strength | 400 - 800 MPa | Static structural connections |

| Surface Hardness | 150 - 300 HV | Increased wear resistance |

| Corrosion Resistance | ≥ 480 hours (salt spray test) | Outdoor applications |

Applications of Non-Preloaded Structural Bolts

Non-preloaded structural bolts are used in a wide range of industrial sectors, where structural safety and stability are essential but where a specific preload is not required. Examples include:

Commercial and Residential Buildings

Example: Use of non-preloaded bolts in load-bearing structures of commercial and residential buildings, where loads are mainly static.

Advantages: Easy installation and lower costs, without compromising structural safety.

Industrial Warehouses

Example: Bolts used to assemble light structures such as industrial warehouses and storage facilities, where connections are subject to static loads.

Advantages: Ensures structural stability with simple and quick installation.

Light Infrastructures

Example: Used in pedestrian bridges, walkways, and other light infrastructures that do not require preloading to ensure safety.

Advantages: Suitable for applications with limited load conditions, reducing maintenance needs.

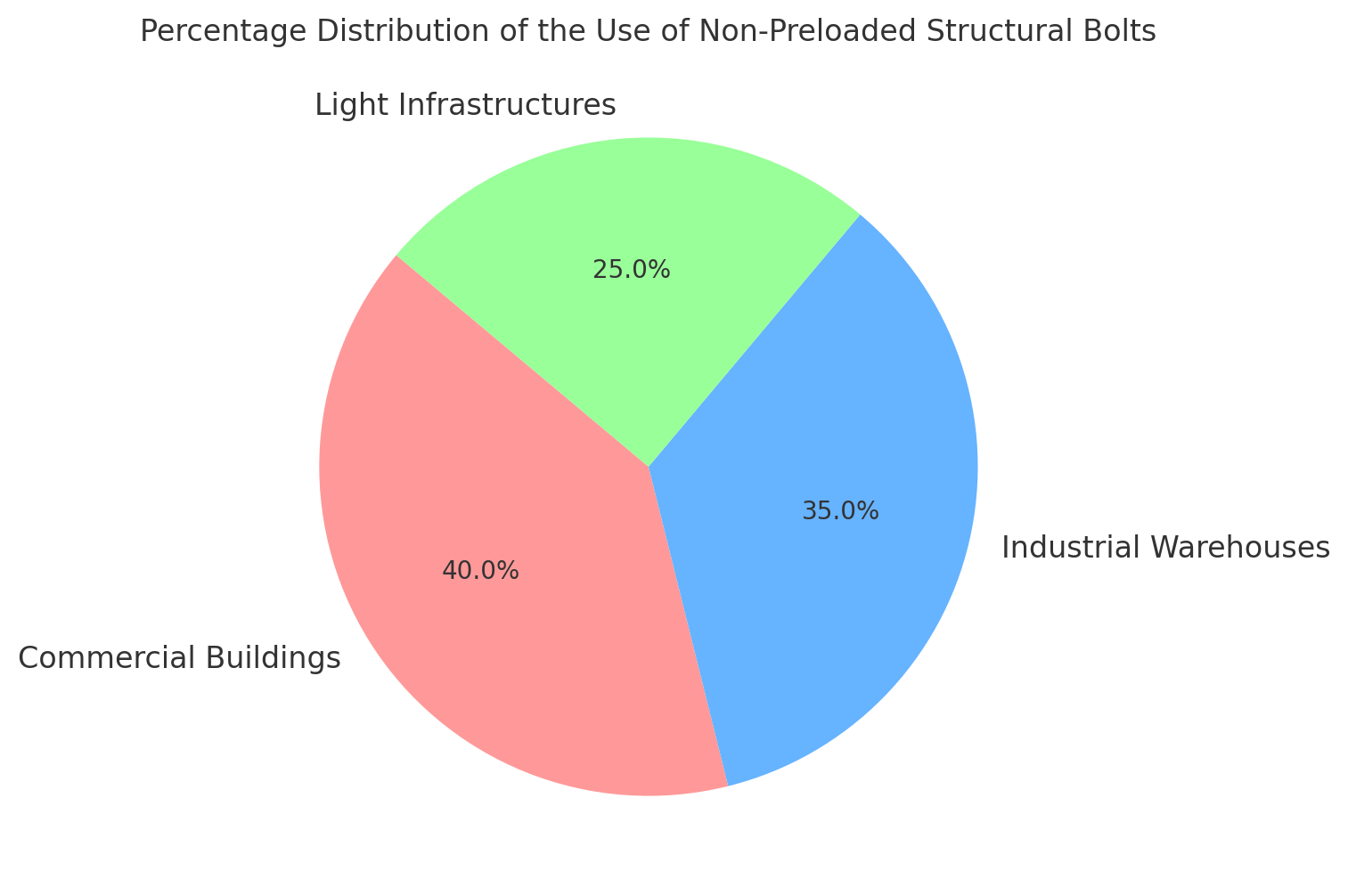

Chart: Distribution of the Use of Non-Preloaded Structural Bolts

The chart below shows the percentage distribution of common applications for non-preloaded structural bolts:

This chart highlights how non-preloaded structural bolts are widely used in commercial buildings, industrial warehouses, and light infrastructures, where traceability and compliance are still essential.

Advantages and Challenges of Using Non-Preloaded Structural Bolts

Advantages:

Ease of Installation: The absence of preload requirements reduces installation complexity, speeding up construction times.

Reduced Costs: Non-preloaded bolts generally involve lower production and installation costs compared to high-strength bolts.

Adaptability: Ideal for a wide range of applications where high preloads are not required, offering flexibility of use.

Challenges:

Limitations in Dynamic Loads: Not suitable for applications with high dynamic loads, where preload would be necessary to prevent slippage.

Maintenance and Control: Although less critical than high-strength bolts, they still require periodic monitoring to ensure long-term safety.

Corrosion Resistance: Despite surface treatments, they may require maintenance in highly aggressive environments.

Business Conclusion

Non-preloaded structural bolts compliant with UNI EN 15048 represent a versatile and cost-effective solution for numerous engineering applications. Although not designed for high dynamic loads, this type of bolting provides adequate strength for static structures, with the advantage of easier installation and reduced costs.

For companies operating in construction and infrastructure, the adoption of non-preloaded structural bolts can lead to significant cost reductions, while maintaining high safety and compliance standards. This type of bolting is particularly useful in projects where speed of execution and economic efficiency are critical, without compromising structural stability.