Combating Metal Corrosion: Phosphating

Introduction

Corrosion is one of the main problems affecting metallic materials, compromising their durability and performance. To combat this phenomenon, several surface treatment techniques exist, including phosphating. Phosphating is a chemical process used to create a protective phosphate layer on the metal surface, improving corrosion resistance and providing an optimal base for further surface treatments such as painting or lubrication. This treatment is widely used in sectors such as automotive, mechanical engineering, and household appliance manufacturing.

What is Phosphating?

Phosphating is a chemical process carried out by immersing or spraying the metal in a solution containing phosphate salts. The result is the formation of a metallic phosphate coating, which may vary in thickness and composition depending on the type of phosphating and the operating conditions.

Types of Phosphating

There are several types of phosphating, each with specific characteristics that make it suitable for different applications.

Iron Phosphating

Description: Iron phosphating produces a thin layer of iron phosphate on the metal surface. This type of phosphating is often used as a pretreatment for painting or powder coating.

Characteristics:

- Coating thickness: 0.5 – 1.5 microns

- Good paint adhesion

- Moderate corrosion protection

Zinc Phosphating

Description: Zinc phosphating is more resistant than iron phosphating and provides superior protection against corrosion. This type of phosphating is often used in corrosive environments or where greater mechanical resistance is required.

Characteristics:

- Coating thickness: 5 – 15 microns

- Excellent base for painting and lubrication

- High corrosion resistance

Manganese Phosphating

Description: Manganese phosphating is mainly used for components requiring high wear and corrosion resistance, such as engine parts and gears. This type of phosphating is also used as a base for the application of lubricating oils.

Characteristics:

- Coating thickness: 10 – 30 microns

- High wear resistance

- Good base for lubrication

Comparative Table: Types of Phosphating

| Type of Phosphating | Coating Thickness (Micron) | Main Characteristics | Typical Applications |

|---|---|---|---|

| Iron Phosphating | 0.5 - 1.5 | Good paint adhesion, moderate protection | Pretreatment for painting, household appliances |

| Zinc Phosphating | 5 - 15 | High corrosion resistance, excellent base for painting | Automotive components, parts exposed to corrosion |

| Manganese Phosphating | 10 - 30 | High wear resistance, good base for lubrication | Engine parts, gears, wear-prone components |

The Phosphating Process

The phosphating process can be divided into several stages, each of which is essential to ensure the quality and effectiveness of the coating.

Surface Preparation

Description: The metal surface must be cleaned of oils, greases, oxides, and other contaminants to ensure good adhesion of the phosphate coating. This step may include alkaline degreasing, acid pickling, and rinsing.

Cleaning Techniques: Alkaline degreasing, acid pickling, sandblasting.

Phosphating

Description: The cleaned metal is immersed in a phosphate solution, where the chemical reaction leads to the formation of the phosphate layer. Bath conditions, such as phosphate concentration, temperature, and immersion time, determine the thickness and composition of the coating.

Critical Parameters:

- Bath temperature: 50 – 90°C

- Immersion time: 5 – 30 minutes

- Phosphate solution concentration

Rinsing and Drying

Description: After phosphating, the component is rinsed to remove chemical residues and then dried. In some cases, an additional treatment such as passivation or lubrication may be applied to improve corrosion and wear resistance.

Post-Treatment Options: Passivation, lubrication, painting.

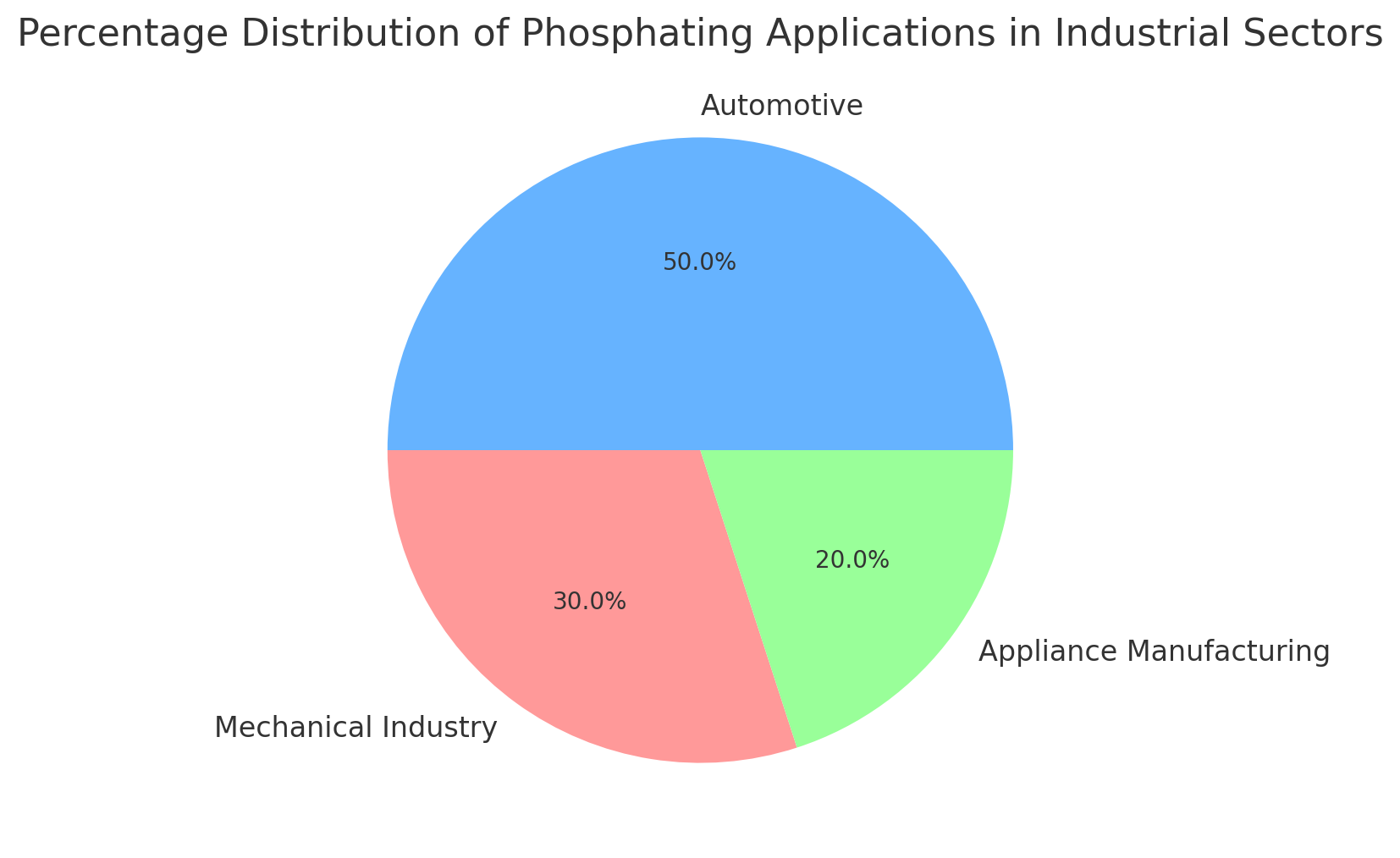

Chart: Distribution of Phosphating Applications

Below is a chart showing the percentage distribution of common phosphating applications across different industrial sectors:

This chart highlights how phosphating is widely used in the automotive sector, mechanical industry, and household appliance manufacturing, where corrosion and wear resistance are essential.

Advantages and Limitations of Phosphating

Advantages:

Corrosion Protection: Phosphating provides effective protection against corrosion, extending the service life of metal components. This is particularly important for applications in humid or aggressive environments.

Excellent Base for Subsequent Treatments: Phosphating creates a porous surface that improves adhesion of paints, lubricants, and other coatings, making it an ideal pretreatment for further finishing processes.

Versatility: Phosphating can be applied to a wide range of metals and alloys, including steel, iron, and zinc, and can be tailored to different needs thanks to the availability of various types of phosphating.

Limitations:

Limited Protection in Extremely Corrosive Environments: Although phosphating offers good corrosion resistance, it may not be sufficient in extremely corrosive environments or under prolonged exposure without additional protective treatments.

Complex Chemical Process: Phosphating requires precise control of bath conditions and surface preparation, which can make the process more complex and costly compared to other surface treatments.

Need for Subsequent Treatments: In many cases, phosphating is only a preliminary stage, and the treated component requires additional coatings or lubrication to achieve the desired performance.

Business Conclusion

Phosphating represents an effective and versatile solution for improving the corrosion and wear resistance of metal components. Thanks to its ability to provide an excellent base for further surface treatments, phosphating is widely used in numerous industrial sectors, including automotive, mechanical engineering, and household appliance manufacturing.