Combating Metal Corrosion: What is Meant by Stainless Steel?

Introduction

Corrosion is a natural phenomenon that leads to the degradation of metallic materials due to chemical reactions with the environment. In many industrial sectors, corrosion represents a significant challenge, affecting the durability, safety, and efficiency of metal components. Among the most effective solutions to combat corrosion, the use of stainless steel (also known as inox steel) stands out for its intrinsic corrosion resistance and versatility across a wide range of applications.

What is Stainless Steel?

Stainless steel is an iron alloy that contains at least 10.5% chromium, the key element that gives this material its characteristic corrosion resistance. In addition to chromium, stainless steel may also contain other alloying elements such as nickel, molybdenum, and manganese, which further enhance its mechanical properties and corrosion resistance.

Mechanism of Corrosion Resistance

The chromium in stainless steel reacts with oxygen in the environment, forming a thin and stable chromium oxide layer on the metal surface. This passive layer acts as a protective barrier, preventing further oxidation of the iron and, consequently, the formation of rust. Although the chromium oxide layer is extremely thin (about 2–3 nanometers), it is highly adherent and self-healing: if the surface is scratched or damaged, the layer quickly reforms in the presence of oxygen.

Classification of Stainless Steels

Stainless steels can be classified into different families, depending on their chemical composition and crystal structure. The three main categories are:

Austenitic Stainless Steel

Description: The most common family of stainless steels, characterized by a face-centered cubic (fcc) austenitic crystal structure, obtained by adding nickel and manganese.

Characteristics:

- Excellent corrosion resistance

- High toughness and ductility

- Non-magnetic

Common Examples: AISI 304, AISI 316

Applications: Food, chemical, and pharmaceutical industries, kitchen equipment, tanks

Ferritic Stainless Steel

Description: These steels have a body-centered cubic (bcc) ferritic crystal structure and contain less nickel than austenitic steels, making them more economical.

Characteristics:

- Good corrosion resistance, but lower than austenitic steels

- Magnetic

- Good oxidation resistance at high temperatures

Common Examples: AISI 430, AISI 409

Applications: Automotive exhaust systems, appliances, construction

Martensitic Stainless Steel

Description: This family is characterized by a martensitic structure obtained through quenching heat treatment. They are high-strength stainless steels.

Characteristics:

- High mechanical strength

- Moderate corrosion resistance

- Magnetic

Common Examples: AISI 410, AISI 420

Applications: Blades, cutting tools, high-strength mechanical components

Table: Comparison of the Main Families of Stainless Steel

| Characteristic | Austenitic Steel | Ferritic Steel | Martensitic Steel |

|---|---|---|---|

| Crystal Structure | Austenitic (fcc) | Ferritic (bcc) | Martensitic |

| Corrosion Resistance | Excellent | Good | Moderate |

| Mechanical Strength | Medium | Medium | High |

| Magnetism | Non-magnetic | Magnetic | Magnetic |

| Typical Applications | Food, chemical, pharmaceutical | Appliances, construction | Tools, mechanical components |

Advantages of Stainless Steel

Corrosion Resistance

Description: Stainless steel is known for its excellent corrosion resistance, making it ideal for aggressive environments, including marine and industrial applications. This property reduces maintenance costs and extends component service life.

Ease of Maintenance

Description: The smooth, non-porous surface of stainless steel is easy to clean and resists dirt and bacterial buildup, making it especially suitable for applications where hygiene is critical, such as in the food and pharmaceutical industries.

Versatility

Description: Thanks to its wide range of alloys and surface finishes, stainless steel can be used in numerous applications, from building construction to the manufacturing of kitchenware.

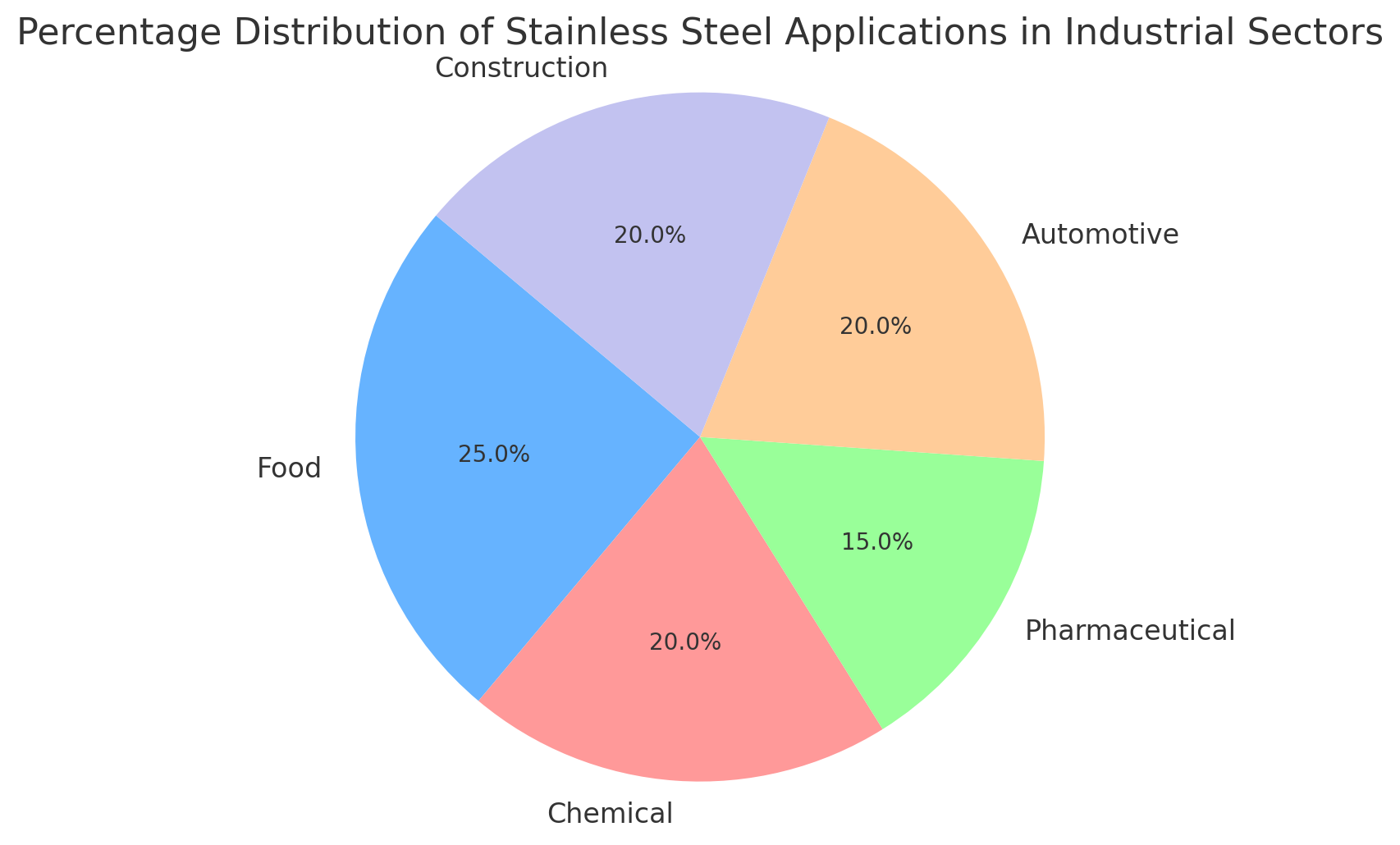

Chart: Distribution of Stainless Steel Applications

Below is a chart showing the percentage distribution of common stainless steel applications across various industrial sectors:

This chart highlights how stainless steel is widely used in the food, chemical, and pharmaceutical sectors, as well as in the automotive and construction industries, where corrosion resistance is a critical factor.

Commercial Conclusion

Stainless steel represents an excellent solution for combating metal corrosion, offering a unique combination of strength, durability, and versatility. Thanks to its ability to resist oxidation and corrosion in a wide range of environments, stainless steel has become an indispensable material in many industrial sectors.

For companies, investing in stainless steel products means offering solutions that not only meet durability and performance requirements but also ensure high aesthetic quality and significantly reduced maintenance costs.