High-Strength Steel: Characteristics

High-Strength Steel: Characteristics

Introduction

High-strength steel is a category of metallic materials that combines high mechanical strength with good ductility, making it ideal for applications requiring both superior structural performance and durability. These steels are widely used in sectors such as automotive, construction, and mechanical engineering, where weight reduction, safety, and fatigue resistance are critical factors. The use of high-strength steels enables the creation of lighter and safer structures, improving production efficiency and environmental sustainability.

Main Characteristics of High-Strength Steels

High-strength steels are distinguished by a set of mechanical and physical properties that determine their suitability for specific applications.

High Mechanical Strength

Description: High-strength steels are designed to provide very high tensile strength, often exceeding 600 MPa. This allows the use of thinner and lighter sections while maintaining the ability to withstand significant loads.

Advantages:

- Reduced structural weight, lowering material costs.

- Increased safety and ability to withstand dynamic loads, such as those in vehicles and bridges.

- Common Examples: Boron steels, microalloyed steels, martensitic steels.

Good Ductility and Formability

Description: Despite their high strength, these steels maintain good ductility, enabling processing methods such as bending, stamping, and rolling. The combination of strength and ductility is particularly important in applications where the material must deform without breaking, such as in the forming of automotive parts.

Advantages:

- Easier processing, even for complex shapes.

- Improved impact and fatigue resistance.

Common Examples: Dual-phase steels, TRIP (Transformation Induced Plasticity) steels.

High Fatigue Resistance

Description: High-strength steels are engineered to withstand high cyclic loads, making them ideal for components subject to repeated stresses, such as springs, axles, and suspensions. Fatigue resistance is essential for ensuring durability and safety under dynamic loads.

Advantages:

- Extended service life of components.

- Reduced risk of sudden failures due to fatigue.

Typical Applications: Automotive components, bridge structures, industrial equipment.

Good Corrosion Resistance

Description: Some high-strength steels, especially those with specific coatings or alloyed with elements such as chromium and nickel, also offer improved corrosion resistance, making them suitable for use in harsh environments.

Advantages:

- Better durability in corrosive environments.

- Lower maintenance needs and associated costs.

Typical Applications: Outdoor infrastructure, marine components, industrial structures.

Comparative Table: Characteristics of High-Strength Steels

| Characteristic | Typical Value | Advantages | Typical Applications |

|---|---|---|---|

| Tensile Strength | >600 MPa | Weight reduction, increased safety | Automotive, construction, infrastructure |

| Ductility | High | Ease of forming, impact resistance | Automotive parts, structural components |

| Fatigue Resistance | High | Extended service life, reduced failures | Springs, suspensions, axles |

| Corrosion Resistance | Variable (depending on type) | Improved durability, lower maintenance | Outdoor infrastructure, marine components |

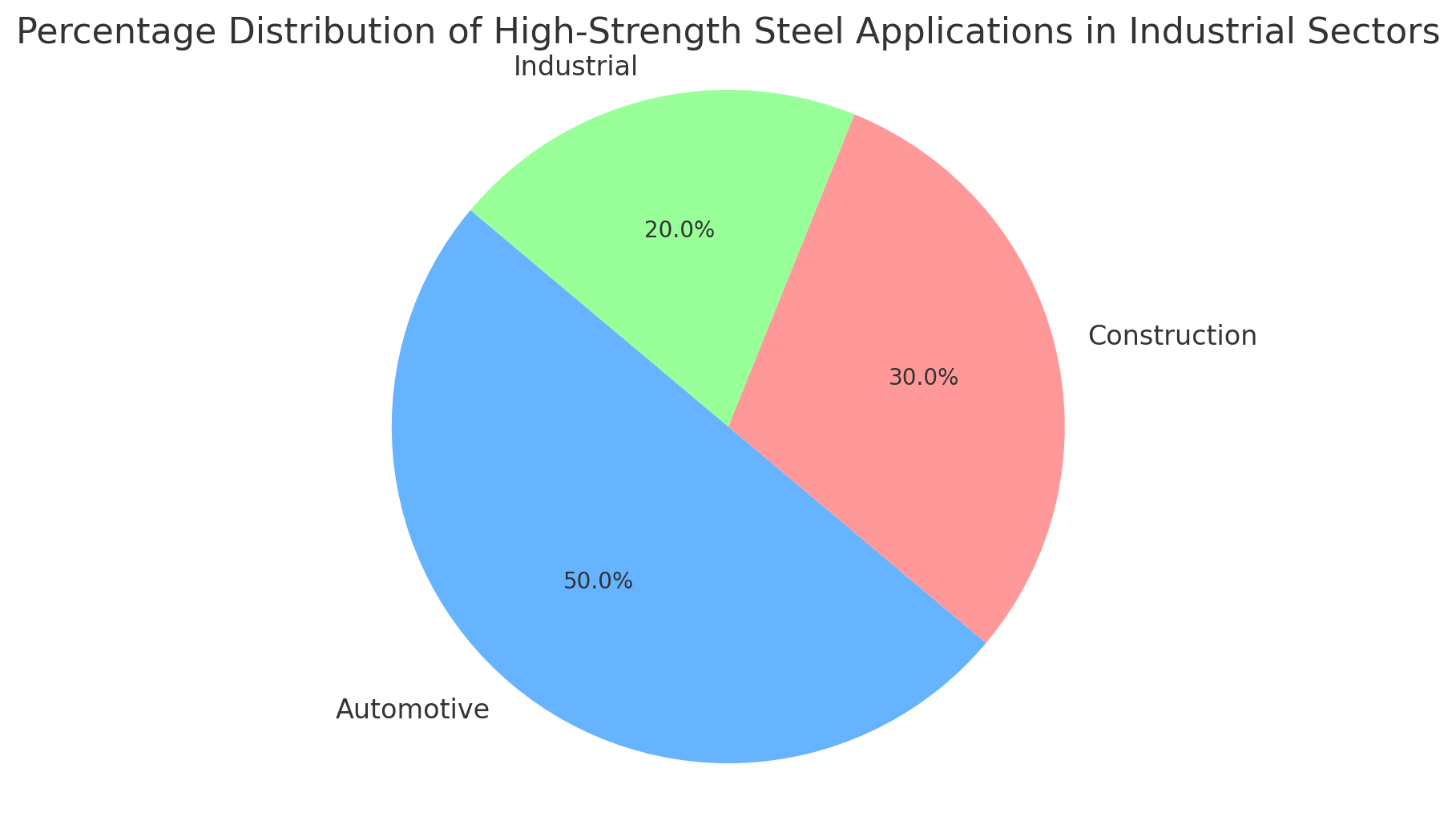

Chart: Distribution of High-Strength Steel Applications

Below is a chart showing the percentage distribution of common high-strength steel applications across various industrial sectors:

This chart highlights how high-strength steels are widely used in automotive, construction, and industrial sectors, where high mechanical performance and durability are essential.

Advantages and Limitations of High-Strength Steels

Advantages:

- Structural Weight Reduction

Description: The use of high-strength steels allows the reduction of material thickness without compromising load-bearing capacity. This results in significant weight savings, particularly advantageous in automotive and aerospace applications. - Increased Safety

Description: Thanks to their high strength and energy absorption capacity, high-strength steels improve the safety of structures and vehicles, reducing risks associated with impacts and dynamic loads. - Economic Efficiency

Description: Although the initial cost of high-strength steels may be higher than that of conventional steels, the weight reduction and increased durability of components lead to significant long-term savings in both materials and operational costs.

Limitations:

- Greater Processing Difficulty

Description: The higher strength of these steels makes processing more complex, requiring advanced equipment and specialized manufacturing processes. This can increase production costs and processing times. - Higher Initial Cost

Description: High-strength steels have a higher cost per unit weight compared to traditional steels, which may pose a barrier for some applications, especially in cost-sensitive sectors. - Fracture Sensitivity

Description: Under certain conditions, such as low temperatures or impact loads, high-strength steels may be more prone to brittle fracture than low-strength steels. This requires careful consideration of operating conditions and design.

Commercial Conclusion

High-strength steels represent an advanced solution for meeting the needs of critical applications where the combination of mechanical strength, durability, and lightness is fundamental. Although they require higher initial investments and more complex processing, the long-term benefits in terms of performance, safety, and economic efficiency are significant.