Mechanical and Physical Properties of Screws

Screws are fundamental fastening elements in many mechanical and structural applications. They are designed to withstand static and dynamic loads, ensuring the proper assembly of mechanical components. The mechanical and physical properties of screws determine their strength, durability, and suitability for specific applications.

Mechanical Properties of Screws

Tensile Strength

Tensile strength is one of the most critical mechanical properties of screws. It is defined as the maximum force a screw can withstand before breaking.

| Screw Type | Tensile Strength (MPa) |

|---|---|

| Carbon Steel | 400 - 1200 |

| Stainless Steel | 500 - 800 |

| Titanium | 900 - 1200 |

| Aluminum Alloys | 200 - 400 |

Hardness

The hardness of a screw determines its resistance to wear and plastic deformation. It is measured in Vickers (HV) or Rockwell (HR) units.

| Screw Type | Hardness (HV) |

|---|---|

| Carbon Steel | 200 - 600 |

| Stainless Steel | 150 - 300 |

| Titanium | 250 - 400 |

| Aluminum Alloys | 60 - 150 |

Physical Properties of Screws

Coefficient of Thermal Expansion

The coefficient of thermal expansion measures the dimensional variation of a screw with changes in temperature.

| Screw Type | Thermal Expansion Coefficient (µm/m°C) |

|---|---|

| Carbon Steel | 11 - 13 |

| Stainless Steel | 15 - 17 |

| Titanium | 8 - 9 |

| Aluminum Alloys | 22 - 24 |

Thermal Conductivity

The thermal conductivity of screws affects their ability to dissipate heat.

| Screw Type | Thermal Conductivity (W/m·K) |

|---|---|

| Carbon Steel | 50 - 60 |

| Stainless Steel | 15 - 25 |

| Titanium | 15 - 21 |

| Aluminum Alloys | 150 - 220 |

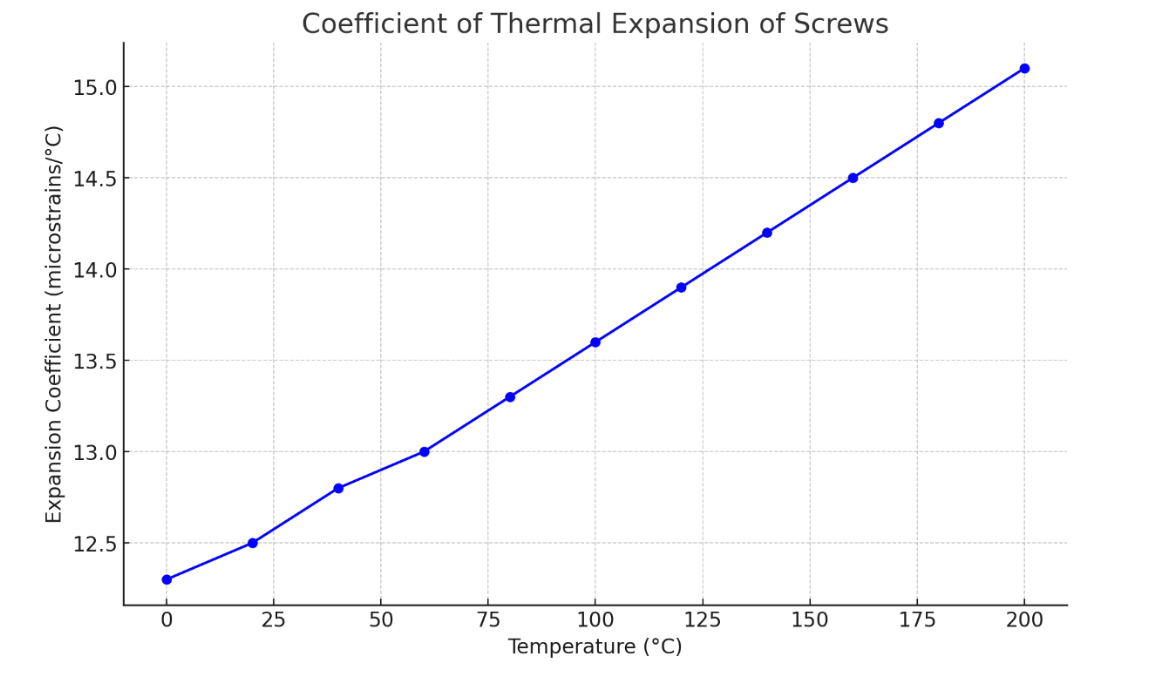

Chart: Thermal Expansion Coefficient of Screws

The chart above shows the thermal expansion coefficient of different types of screws based on the material they are made of.

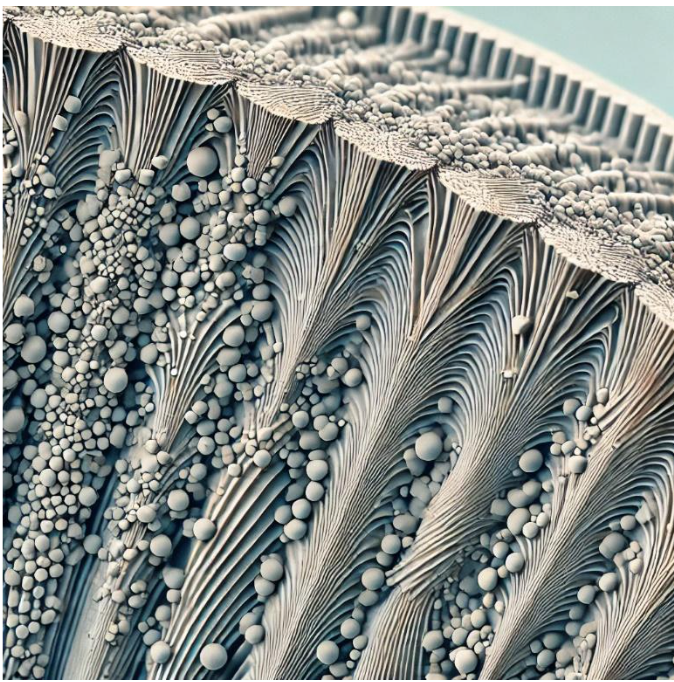

Microstructure Images

The following image shows the typical microstructure of a carbon steel screw:

Conclusion

Screws are essential components in numerous industrial and commercial applications. The choice of the correct screw depends on the specific requirements of the application, such as tensile strength, hardness, thermal expansion capacity, and thermal conductivity. Investing in high-quality screws ensures a safe and durable fastening, improving the reliability and efficiency of final products.

For companies seeking to optimize their production processes, partnering with experienced and reliable screw suppliers is crucial. A competent supplier can provide technical advice on the selection of the most appropriate materials and surface treatments, ensuring that screws meet the required quality standards.