Metal Surface Coatings: What They Are and What They Are For

Introduction

Metal surface coatings represent one of the most important technologies for improving the performance and durability of metallic materials. These treatments are applied to protect metals from corrosion, wear, and oxidation, and to enhance the aesthetic or functional properties of surfaces. In many industrial sectors, such as automotive, aerospace, construction, and electronics, surface coatings are essential to ensure that metal components can withstand harsh environmental conditions and meet the required technical specifications.

What Are Surface Coatings?

Surface coatings are layers of materials applied to the surface of a metallic substrate to improve its physical, chemical, and mechanical properties. These coatings can be metallic, organic, ceramic, or polymer-based, and are selected according to the specific application and the operating conditions to which the component will be exposed. Coatings can be applied through various techniques, including electroplating, galvanizing, painting, thermal spraying, and PVD (Physical Vapor Deposition).

Types of Surface Coatings

Description: Metallic coatings consist of layers of metals such as zinc, nickel, chromium, or copper applied to the base metal surface. These coatings provide corrosion protection, improve surface hardness, and can deliver an aesthetic finish.

Examples:

- Galvanizing: Protects iron and steel from corrosion by depositing a layer of zinc.

- Nickel Plating: Provides good corrosion resistance and a bright decorative appearance.

- Chromium Plating: Used to improve wear resistance and give a polished finish.

Organic Coatings

Description: These coatings include paints, enamels, epoxies, and polymers applied to the metal surface to protect against corrosion, provide electrical insulation, or improve aesthetics.

Examples:

- Powder Coating: A technique using polymer powders that are electrostatically applied and then cured, forming a strong and durable coating.

- Epoxy Coatings: Offer excellent anti-corrosive and chemical resistance, mainly used in marine and industrial environments.

Ceramic Coatings

Description: Ceramic coatings provide excellent protection against wear, oxidation, and high temperatures. They are especially suitable for applications in highly aggressive environments.

Examples:

- Aluminum Oxide (Al₂O₃): Known for its hardness and abrasion resistance.

- Titanium Nitride (TiN): Applied to cutting tools to improve wear resistance and reduce friction.

PVD Coatings (Physical Vapor Deposition)

Description: This vapor deposition process creates a thin yet highly durable coating on the metal surface, enhancing properties such as hardness, wear resistance, and aesthetics.

Examples:

- PVD Coatings on Mechanical Components: Improve wear resistance and aesthetics of components exposed to severe operating conditions.

Table: Comparison of Different Types of Surface Coatings

| Type of Coating | Base Material | Typical Applications | Main Advantages |

|---|---|---|---|

| Metallic Coatings | Zinc, Nickel, Chrome | Mechanical components, automobiles | Corrosion resistance, hardness, aesthetics |

| Organic Coatings | Paints, Epoxies | Appliances, outdoor structures | Anti-corrosion protection, electrical insulation |

| Ceramic Coatings | Aluminum oxide, TiN | Cutting tools, high-temperature components | Wear resistance, thermal resistance |

| PVD Coatings | Metals and ceramics | High-precision components | Surface hardness, wear resistance, aesthetics |

Application Processes of Surface Coatings

Electroplating

Description: An electrochemical process in which a metallic coating is deposited on the base metal surface by immersing it in an electrolyte bath and applying electric current.

Applications: Used for galvanizing, nickel plating, and chromium plating.

Advantages:

- High uniformity of coating.

- Ability to achieve high-quality decorative finishes.

Powder Coating

Description: A technique where polymer powder is electrostatically applied to the metal surface and then cured at high temperature to create a hard, resistant coating.

Applications: Metal structures, appliances, automotive.

Advantages:

- Resistance to corrosion and chemicals.

- Wide range of available colors and finishes.

Thermal Spraying

Description: A process in which coating materials such as metals or ceramics are heated and sprayed onto the metal surface to create a protective layer.

Applications: Aerospace components, turbines, valves.

Advantages:

- Protection against wear and corrosion.

- Applicable to a wide variety of materials.

PVD Deposition

Description: A physical vapor deposition process in which a thin coating is applied under vacuum onto the metal surface, improving hardness and wear resistance.

Applications: Precision components, cutting tools, decorative items.

Advantages:

- Extreme surface hardness.

- Reduced friction and enhanced aesthetics.

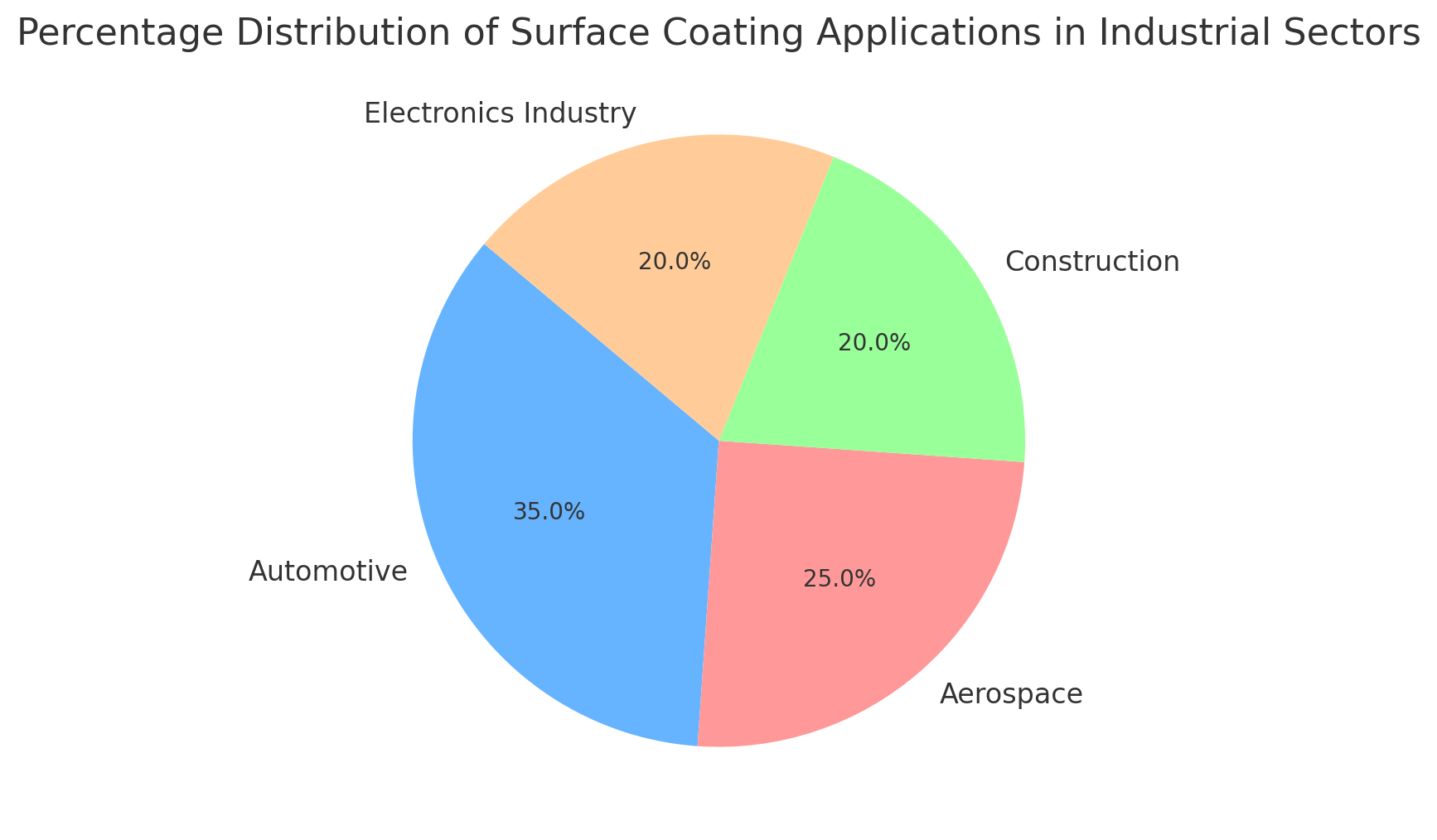

Chart: Distribution of Surface Coating Applications

Below is a chart showing the percentage distribution of common applications of surface coatings in various industrial sectors:

This chart highlights how surface coatings are widely used in the automotive, aerospace, construction, and electronics industries, where corrosion protection and durability are essential.

Business Conclusion

Metal surface coatings are essential to ensure the durability, corrosion resistance, and aesthetics of metallic components across numerous industrial sectors. Investing in advanced coating technologies allows companies to improve the quality and longevity of their products while reducing maintenance costs.