PPAP Levels (Production Part Approval Process)

The Production Part Approval Process (PPAP) is a procedure used in the automotive industry and other manufacturing sectors to ensure that supplies and components meet customer requirements and specifications. PPAP is essential to guarantee that any changes in production processes do not compromise the quality of the final products.

There are five levels of PPAP, each with specific requirements in terms of documentation and verification.

PPAP Levels

Level 1: Warrant Only

Includes only the Part Submission Warrant (PSW) signed by the supplier.

Level 2: PSW with Product Samples and Limited Supporting Data

Includes the PSW, product samples, and limited supporting data.

Level 3: PSW with Product Samples and Complete Supporting Data

The most common level, requiring the PSW, product samples, and full supporting documentation.

Level 4: PSW and Other Customer-Specific Requirements

Includes the PSW along with additional requirements defined by the customer.

Level 5: PSW with Product Samples and On-Site Supplier Verification

The most rigorous level, including the PSW, product samples, complete documentation, and an on-site verification at the supplier’s facility.

Documentation and Requirements

Each PPAP level requires specific documentation. Below is a summary table of the main documents required:

| Document | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|---|---|---|---|---|

| Part Submission Warrant (PSW) | X | X | X | X | X |

| Product Drawings | X | X | X | ||

| Material Specifications | X | X | X | ||

| Dimensional Analysis | X | X | X | ||

| Test Reports | X | X | X | ||

| Control Plan | X | X | X | ||

| Measurement System Analysis (MSA) Report | X | X | |||

| Process Capability Study | X | X | |||

| Quality Certifications | X | X |

Analysis and Charts

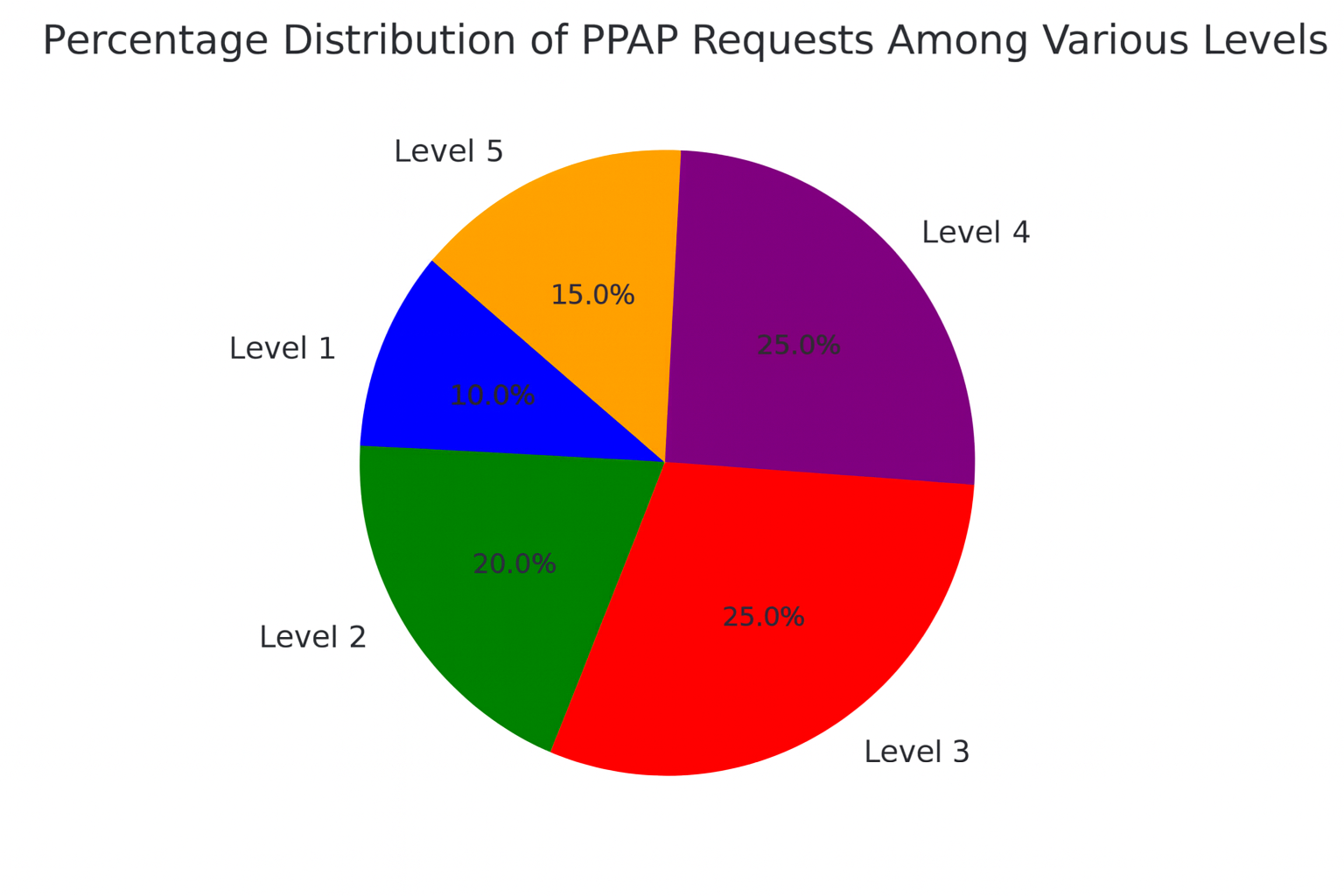

Distribution of PPAP Requests by Level

The following chart shows the percentage distribution of PPAP requests among the various levels in a typical automotive supply scenario:

Benefits of PPAP

Proper implementation of the PPAP process provides numerous benefits:

- Product Quality: Ensures that supplied products meet the required specifications.

- Risk Reduction: Minimizes the risk of production defects.

- Operational Efficiency: Improves operational efficiency through better management of production processes.

- Customer Satisfaction: Increases customer satisfaction by ensuring on-time deliveries and compliant products.

Conclusion

PPAP is not just a regulatory requirement; it represents a strategic opportunity to improve product quality, optimize production processes, and strengthen customer relationships. Implementing an effective PPAP can make the difference between being just another supplier and becoming a trusted partner.

Investing in PPAP means investing in quality, risk reduction, and ultimately, customer satisfaction. In a competitive market, the ability to demonstrate a robust and reliable part approval process can set your company apart, offering a significant advantage over competitors.

Choosing to properly implement PPAP means choosing excellence.