Self-Locking Nuts

Introduzione

The loosening of threaded joints is a leading cause of mechanical failure, especially in applications subject to vibrations, dynamic loads, and thermal variations. For stainless steels, known for their corrosion resistance and durability, choosing solutions that prevent loosening is crucial for ensuring the reliability of structures and components. Self-locking nuts are an effective solution for counteracting loosening in threaded joints, offering superior resistance thanks to integrated mechanisms that increase friction and prevent relative movement between the threads.

Self-Locking Nuts: Principles of Operation

Self-locking nuts are designed to maintain a stable tightening even under adverse operating conditions. Their effectiveness comes from mechanisms that increase internal friction, preventing relative motion between the nut and the bolt. There are several types of self-locking nuts, each with specific characteristics.

- Nyloc Nut (with Nylon Insert)

- Description: This type of nut incorporates a nylon ring in the upper part, which slightly deforms when the nut is tightened onto the bolt. The nylon insert generates additional friction, preventing spontaneous loosening.

- Applications: Used in general mechanical and automotive applications, and in sectors where weight and space are limited. It's ideal for environments that don't exceed the maximum operating temperature of nylon.

- Adhesive-Coated Nut

- Description: This nut uses a small amount of adhesive applied to the internal thread, which activates during tightening. The adhesive creates a chemical bond that prevents the nut from moving.

- Applications: Suitable for permanent or semi-permanent joints in environments that require resistance to vibrations and shocks.

- Prevailing-Torque Nut

- Description: These nuts are designed with a slight deformation in the internal thread, which increases friction during tightening. The torque required to screw the nut on is predetermined, ensuring controlled tightening.

- Applications: Used in industrial applications where controlled, vibration-resistant tightening is necessary, such as in the aerospace and railway sectors.

Table: Characteristics of Different Types of Self-Locking Nuts

| Type of Self-Locking Nut | Mechanism | Typical Applications |

|---|---|---|

| Nylon Insert Nut | Nylon insert that increases friction | General mechanics, automotive, construction |

| Adhesive-Coated Nut | Adhesive on the internal thread | Permanent applications, high resistance |

| Prevailing-Torque Nut | Deformed internal thread, controlled tightening | Aerospace, railway, industrial mechanics Export to Sheets |

Advantages of Using Self-Locking Nuts in Stainless Steel

Stainless steels are high-quality materials known for their corrosion resistance and excellent mechanical properties, but their combination with solutions like self-locking nuts can further improve the performance of threaded joints. Below are the main advantages.

- Superior Loosening Resistance

- Description: Thanks to their locking mechanisms, self-locking nuts drastically reduce the possibility of spontaneous loosening of joints, even under conditions of vibration and cyclic loads. This is particularly important for stainless steels, where mechanical resistance must be maintained over time.

- Durability in Corrosive Environments

- Description: Stainless steel self-locking nuts maintain their effectiveness even in highly corrosive environments, typical of sectors like the chemical industry, oil & gas, and marine applications. The combination of corrosion resistance and stable tightening ensures a long service life for the joints.

- Ease of Maintenance and Reusability

- Description: Many self-locking nuts, especially those with nylon inserts, can be reused after disassembly, reducing maintenance costs and improving operational efficiency. This is particularly advantageous in contexts where regular maintenance is required.

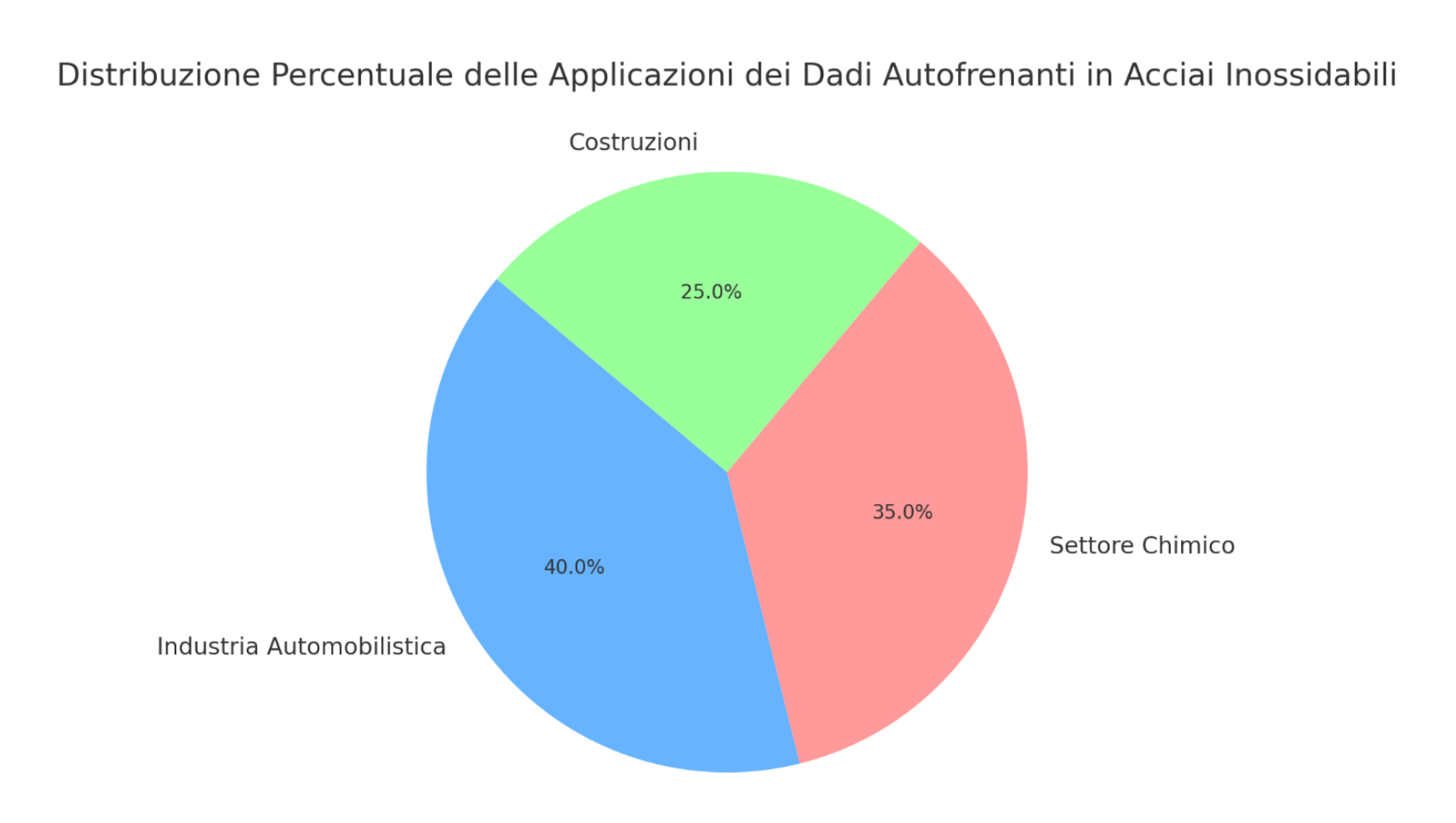

Graph: Distribution of Self-Locking Nut Applications in Stainless Steels

Below is a graph showing the percentage distribution of common applications of stainless steel self-locking nuts across different industrial sectors: This graph highlights how self-locking nuts are widely used in the automotive, chemical, and construction sectors, where corrosion resistance and tightening stability are essential.

Advantages and Challenges of Using Self-Locking Nuts in Stainless Steel

Advantages:

- High Corrosion Resistance: Stainless steels, combined with self-locking nuts, offer exceptional corrosion resistance, which is particularly useful in marine and chemical applications.

- Tightening Reliability: Self-locking nuts maintain a stable tightening even under strong vibration, increasing the safety and durability of the joints.

- Operational Efficiency: The reusability of self-locking nuts reduces maintenance and replacement costs, improving the efficiency of industrial operations.

Challenges:

- Higher Cost: Stainless steel self-locking nuts tend to have a higher initial cost than standard nuts due to the materials and technology used.

- Limited to Specific Temperatures: Nuts with nylon inserts may be limited to specific operating temperatures, which could restrict their use in high-temperature environments.

- Requires Precise Installation: To ensure the effectiveness of self-locking nuts, a correct tightening torque must be applied, which may require specific tools and trained personnel.

Commercial Conclusion

Stainless steel self-locking nuts represent an advanced solution for preventing the loosening of threaded joints in difficult environments and critical applications. Although their initial cost may be higher than traditional nuts, the benefits in terms of corrosion resistance, tightening reliability, and long-term maintenance cost reduction make them an ideal choice for high-responsibility sectors.