Stainless Steel A2 and A4: Differences and Characteristics

Introduction

Stainless steels are a class of materials widely used in multiple industrial sectors thanks to their excellent corrosion resistance, durability, and ease of maintenance. Among the various categories of stainless steels, A2 and A4 grades are particularly common, employed in applications that require resistance to corrosion and harsh environmental conditions. Although similar in many respects, they exhibit significant differences that influence their selection for specific applications.

General Characteristics

Stainless steels A2 and A4 belong to the austenitic family, alloys primarily based on iron, chromium, and nickel. Austenite, a non-magnetic phase of iron, gives these steels their corrosion resistance and good mechanical properties. However, the presence of other alloying elements, such as molybdenum, introduces key differences between A2 and A4 stainless steel.

Stainless Steel A2

Chemical Composition:

- Chromium (Cr): 16–18%

- Nickel (Ni): 8–10%

- Carbon (C): ≤ 0.08%

- Manganese (Mn): ≤ 2%

- Phosphorus (P): ≤ 0.045%

- Sulfur (S): ≤ 0.015%

Properties:

Corrosion Resistance: Good, suitable for general applications in mildly aggressive environments, such as indoor or outdoor settings not exposed to chlorides or strong acids.

Mechanical Strength: High, with good ductility and toughness.

Magnetism: Non-magnetic in the annealed state.

Typical Applications:

- Fastening components (screws, bolts, nuts) for general use.

- Steel structures in mildly corrosive environments.

- Kitchen utensils and household items.

Stainless Steel A4

Chemical Composition:

- Chromium (Cr): 16–18%

- Nickel (Ni): 10–14%

- Molybdenum (Mo): 2–3%

- Carbon (C): ≤ 0.08%

- Manganese (Mn): ≤ 2%

- Phosphorus (P): ≤ 0.045%

- Sulfur (S): ≤ 0.015%

Properties:

- Corrosion Resistance: Excellent, thanks to the presence of molybdenum, which provides superior protection against corrosion in chloride-rich, marine, and acidic environments.

- Mechanical Strength: Comparable to A2, but with significantly enhanced corrosion resistance.

- Magnetism: Non-magnetic in the annealed state.

Typical Applications:

- Fastening components for marine or highly corrosive environments.

- Equipment for the chemical and petrochemical industry.

- Structures exposed to seawater or harsh industrial environments.

Comparative Table: A2 vs A4

| Characteristic | Stainless Steel A2 | Stainless Steel A4 |

|---|---|---|

| Main Chemical Composition | Cr: 16-18%, Ni: 8-10% | Cr: 16-18%, Ni: 10-14%, Mo: 2-3% |

| Corrosion Resistance | Good (general environment) | Excellent (marine and acidic environment) |

| Mechanical Strength | High | High |

| Magnetism | Non-magnetic (annealed state) | Non-magnetic (annealed state) |

| Typical Applications | Fastening components, indoor structures | Marine fastening components, chemical equipment |

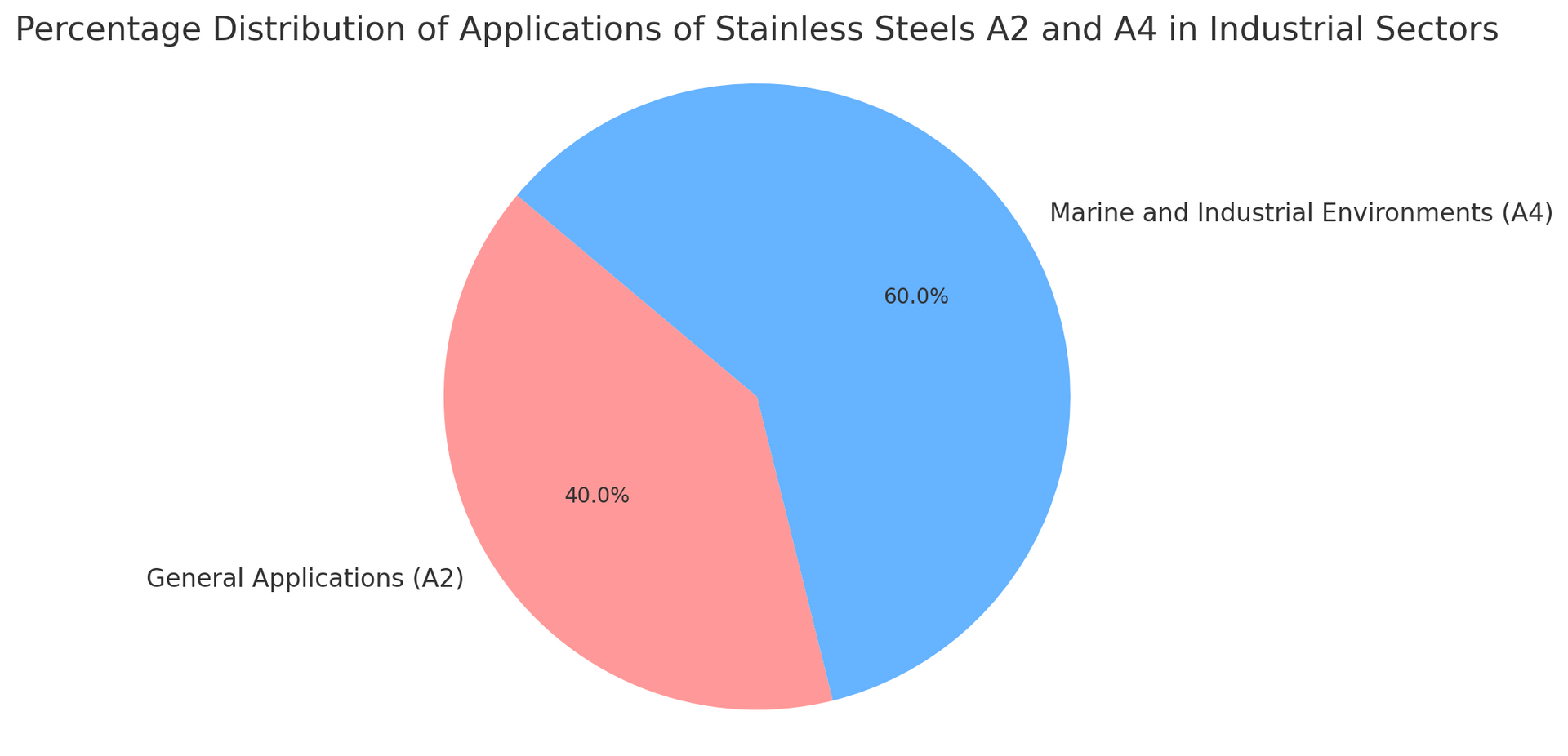

Chart: Application Distribution of Stainless Steels A2 and A4

Below is a chart showing the percentage distribution of common applications of A2 and A4 stainless steels across various industrial sectors:

This chart highlights how A4 is predominant in highly corrosive environments such as marine and industrial contexts, while A2 is more commonly used in general applications where environmental conditions are less aggressive.

Advantages and Limitations of Stainless Steel A2 and A4

Advantages of Stainless Steel A2:

- Lower Cost: The absence of molybdenum makes A2 less expensive than A4 while still maintaining good mechanical properties and corrosion resistance in non-aggressive environments.

- Wide Availability: One of the most widely used stainless steels, easily available on the market.

- Ease of Processing: A2 is easy to machine, weld, and form.

Limitations of Stainless Steel A2:

- Limited Corrosion Resistance: Not suitable for environments with chlorides, seawater, or aggressive acids.

- Restricted Applications: Its use is limited to contexts not exposed to highly corrosive environments.

Advantages of Stainless Steel A4:

- Superior Corrosion Resistance: The addition of molybdenum significantly improves corrosion resistance, making it ideal for marine and chemical environments.

- Applications in Extreme Environments: The preferred choice for applications where durability and corrosion resistance are critical.

Limitations of Stainless Steel A4:

- Higher Cost: The presence of molybdenum makes A4 more expensive than A2.

- Processing Difficulty: Can be more difficult to machine compared to A2, requiring specialized equipment and techniques.

Commercial Conclusion

The choice between A2 and A4 stainless steel largely depends on the environmental conditions in which the component will be used and the specific requirements of the application. While both grades offer excellent mechanical properties and good corrosion resistance, A4 represents the best choice for highly corrosive environments, such as marine or industrial settings, thanks to the presence of molybdenum. On the other hand, A2 is a cost-effective and widely used solution for less demanding applications.