What is Hydrogen Embrittlement?

Introduction

Hydrogen embrittlement is a metallurgical phenomenon that can seriously compromise the structural integrity of metallic materials, especially in high-strength steels and titanium alloys. This phenomenon occurs when hydrogen penetrates the metal’s crystal lattice, causing a reduction in ductility and fracture resistance. The result is brittle behavior, even under loads below the material’s elastic limit, which can lead to catastrophic and unexpected failures.

Mechanism of Hydrogen Embrittlement

Hydrogen embrittlement occurs through several stages, involving hydrogen absorption, its diffusion within the material, and finally its interaction with the crystal lattice of the metal.

Hydrogen Absorption

Description: Hydrogen can enter the metal through various industrial processes such as acid pickling, galvanizing, welding, or exposure to corrosive environments. In some cases, hydrogen can also penetrate through electrochemical processes such as galvanic corrosion.

Main Causes:

- Surface finishing processes (e.g., electro-galvanizing).

- Corrosion reactions in humid or acidic environments.

- Exposure to high-pressure gaseous hydrogen.

Hydrogen Diffusion

Description: Once absorbed, hydrogen diffuses within the crystal lattice of the metal, concentrating preferentially at defects such as dislocations, grain boundaries, inclusions, and microcracks. This diffusion is facilitated at high temperatures but can also occur at room temperature in particularly susceptible materials.

Effects:

- Accumulation of hydrogen in structural defects.

- Hydride formation in susceptible materials, such as titanium.

Interaction with the Crystal Lattice

Not all metallic materials are equally susceptible to hydrogen embrittlement. High-strength steels, titanium alloys, and some types of stainless steels are particularly vulnerable. Below is an overview of the effects of hydrogen embrittlement on some common materials.

High-Strength Steels

Description: High-strength steels, such as martensitic and bainitic steels, are highly susceptible to hydrogen embrittlement due to their high hardness and the presence of complex microstructures that promote hydrogen diffusion.

Typical Applications: Screws, bolts, structural components for automotive and aerospace industries.

Effects:

- Sudden fracture under static or dynamic load.

- Significant reduction in fatigue life.

Titanium Alloys

Description: Titanium alloys are known for their high specific strength and excellent corrosion resistance. However, these alloys can form brittle titanium hydrides, which can cause intergranular fractures.

Typical Applications: Aerospace components, medical implants, marine applications.

Effects:

- Formation of microcracks due to hydride precipitation.

- Intergranular fracture under stress.

Stainless Steels

Description: Some stainless steels, particularly high-strength grades, can be susceptible to hydrogen embrittlement, especially if exposed to acidic conditions or during welding processes.

Typical Applications: Tanks, pipelines, chemical equipment.

Effects:

- Loss of toughness.

- Increased susceptibility to stress corrosion cracking.

Table: Effects of Hydrogen Embrittlement on Different Materials

| Material | Susceptibility to Embrittlement | Main Effects | Typical Applications |

|---|---|---|---|

| High-Strength Steels | High | Sudden fracture, reduced fatigue life | Screws, bolts, structural components |

| Titanium Alloys | Moderate | Hydride formation, intergranular fracture | Aerospace components, medical and marine equipment |

| Stainless Steels | Variable | Loss of toughness, stress corrosion cracking | Tanks, pipelines, chemical equipment |

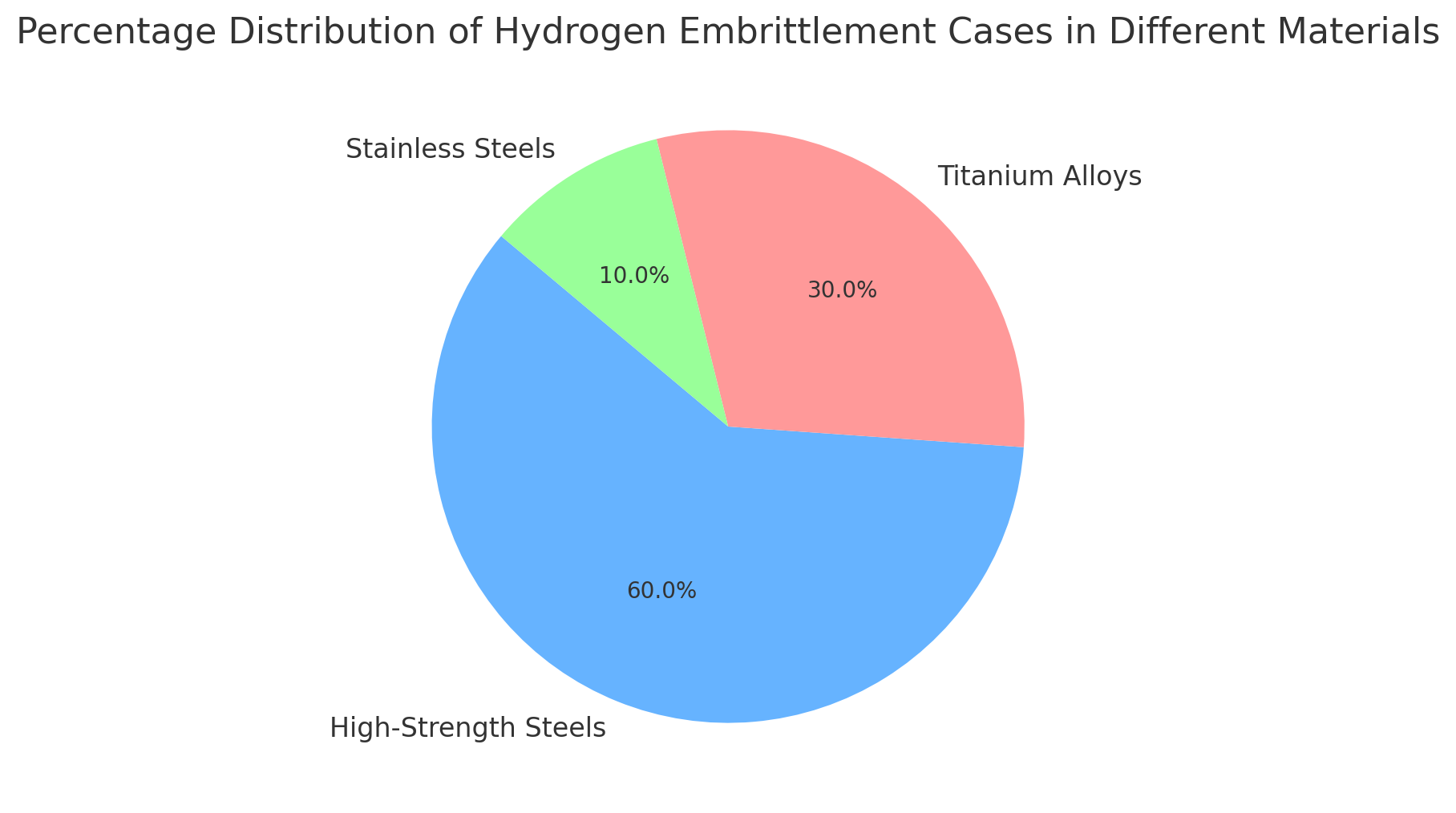

Chart: Distribution of Hydrogen Embrittlement Cases in Different Materials

This chart shows the percentage distribution of hydrogen embrittlement cases observed in different materials: high-strength steels are the most affected, followed by titanium alloys and stainless steels.

Prevention and Mitigation of Hydrogen Embrittlement

Material Selection

Description: Choose materials less susceptible to hydrogen embrittlement or with chemical compositions that limit hydrogen absorption.

Strategy: Use alloys with elements that inhibit hydrogen diffusion, such as vanadium in steels.

Process Control

Description: Implement manufacturing processes that reduce hydrogen introduction, such as post-process heat treatments to promote hydrogen diffusion and release from the material.

Strategy: Apply degassing treatments, minimize exposure to acid baths, and use protective coatings.

Proper Design

Description: Design components to minimize stress concentration and defects that can facilitate hydrogen diffusion.

Strategy: Avoid geometries that create stress concentrators and ensure proper surface finishing.

Business Conclusion

Hydrogen embrittlement represents a major challenge for many industries, with potentially disastrous consequences in terms of safety and reliability. Understanding this phenomenon and adopting preventive measures is crucial for companies aiming to guarantee the quality and durability of their products.

Investing in proper material selection, optimized manufacturing processes, and engineering design can reduce the risk of hydrogen embrittlement, protect investments, and increase customer satisfaction.