Methods for proper tightening

Introduzione

Tightening is one of the fundamental operations in mechanical assembly. Proper tightening ensures the safety and reliability of joints, preventing loosening, breakage, and premature failures. Various methods can be used to achieve correct tightening, each with its own advantages and limitations. This document explores the main tightening methods and provides practical guidelines for their application.

Tightening Methods

Torque Tightening

Torque tightening is the most common method, using a torque wrench to apply a specific force.

Advantages:

- Easy to use

- Good accuracy

Limitations:

- Accuracy depends on proper calibration of the wrench

- Does not account for variations in thread friction

Tools:

- Torque wrench

- Recommended torque tables (see Table 1)

Table 1: Recommended Torque Values

| Thread Type | Diameter (mm) | Torque (Nm) |

|---|---|---|

| M6 | 6 | 10 |

| M8 | 8 | 25 |

| M10 | 10 | 50 |

| M12 | 12 | 85 |

Angle Tightening Method

The angle tightening method involves applying an additional rotation angle after the initial torque tightening.

Advantages:

- High accuracy

- Compensates for variations in thread friction

Limitations:

- Requires specialized tools

- More complex to execute

Tools:

- Angle wrench

- Rotation angle tables (see Table 2)

Table 2: Recommended Rotation Angles

| Thread Type | Diameter (mm) | Angle (degrees) |

|---|---|---|

| M6 | 6 | 60 |

| M8 | 8 | 90 |

| M10 | 10 | 120 |

| M12 | 12 | 150 |

Bolt Stretching Method

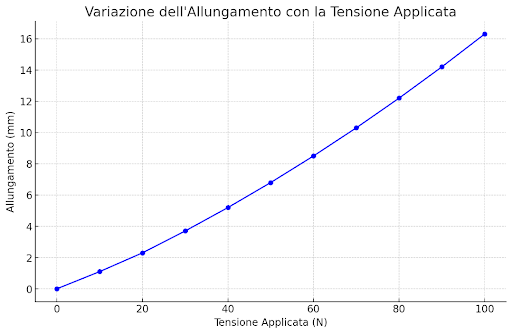

The bolt stretching method uses tools to measure the bolt’s elongation directly, ensuring precise tension.

Advantages:

- Maximum precision

- Suitable for critical applications

Limitations:

- Expensive

- Requires specialized equipment

Tools:

- Strain gauge

- Elongation measurement system

Graph 1: Variation of Elongation with Applied Tension

Application Example

Consider an M10 bolted joint in a critical metal structure. Using the angle tightening method, an initial tightening of 50 Nm is applied, followed by a 120-degree rotation. Proper application of this method has demonstrated greater reliability and longevity compared to torque tightening alone.

Conclusion

Proper tightening is essential to ensure the safety and efficiency of your mechanical applications. Using the appropriate tightening methods not only extends component lifespan but also reduces maintenance costs and downtime. Choosing high-quality tools and following technical recommendations allows for optimal results and ensures that each joint is properly tightened. Investing in the right tightening methods today guarantees the continuity and reliability of your operations in the future.