Punching

Punching is a mechanical processing technique used to cut or shape materials using a punch and die. In the fastener industry, punching is essential for producing components like screws, bolts, washers, and other fastening elements. This process offers high precision, efficiency, and repeatability, making it ideal for mass production.

Principles of Punching

Punching Process

The punching process involves the following steps:

- Material Preparation: The raw material, usually a metal sheet, is placed on the die.

- Punch Application: The punch is pressed against the material with high force, cutting it along the contours of the die.

- Part Ejection: The punched part is ejected from the die, ready for further processing or assembly.

Equipment Used

- Punch: Made from high-strength steel, it must maintain sharpness and precision to ensure clean cuts.

- Die: The structure that supports the material and determines the shape of the punched part.

- Press: The machine that provides the necessary force for the punching process.

Key Punching Parameters

Material Properties

| Material | Hardness (HV) | Typical Thickness (mm) | Typical Applications |

|---|---|---|---|

| Carbon Steel | 120-180 | 0.5-3.0 | Screws, bolts, washers |

| Stainless Steel | 200-300 | 0.3-2.5 | Corrosion-resistant fasteners |

| Aluminum | 30-70 | 0.5-5.0 | Lightweight components |

| Brass | 100-150 | 0.4-4.0 | Decorative and functional components |

Process Parameters

| Parameter | Typical Value |

|---|---|

| Punching Force | 10-100 tons |

| Punching Speed | 60-300 strokes/minute |

| Punch-Die Clearance | 5-15% of material thickness |

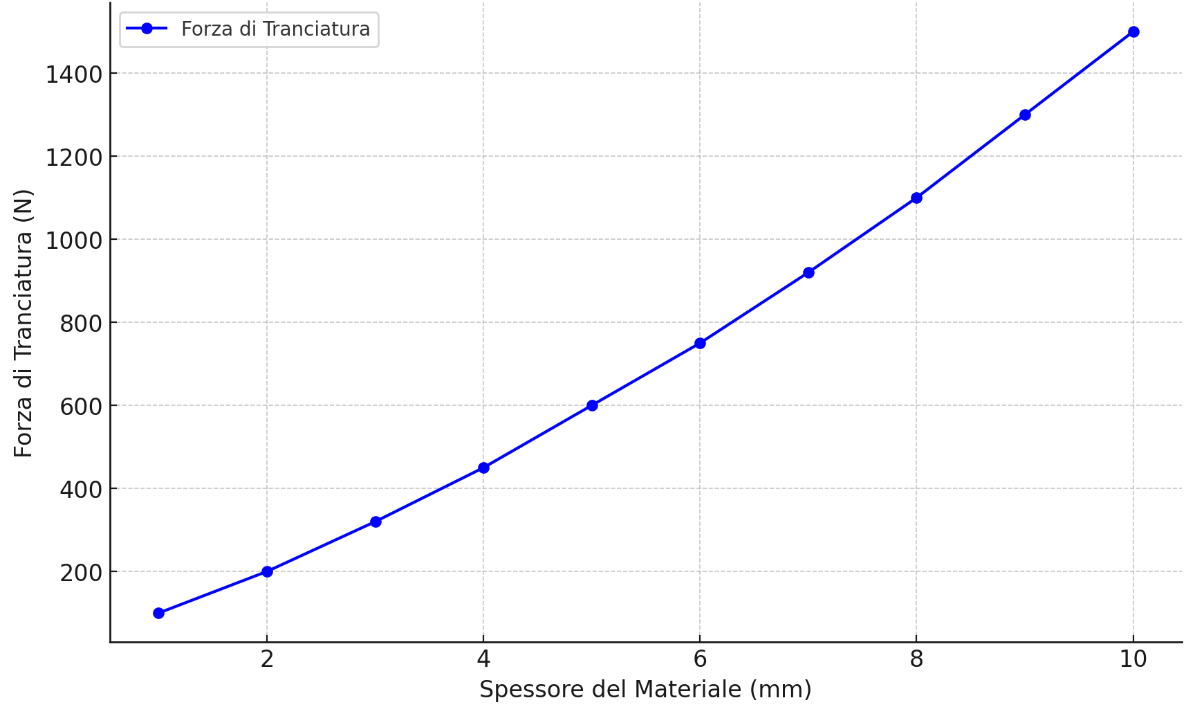

Graph: Material Thickness vs Punching Force

The graph above shows how punching force varies as a function of material thickness for different types of metals.

Images of the Stamping Process

The following image shows a stamping press in action:

Advantages of Punching

- High Precision: Allows the production of components with tight tolerances and clean edges.

- Efficiency: Suitable for mass production with high volumes and fast production cycles.

- Versatility: Can be used for a wide range of materials and thicknesses.

- Waste Reduction: Optimizing the layout of parts on the sheet minimizes material waste.

Conclusion

Punching represents a key technology in the fastener industry, providing efficient and precise solutions for the production of fastening elements. Investing in high-quality punching equipment and appropriate materials can significantly improve productivity and the quality of finished products. Collaborating with experienced and reliable suppliers ensures the procurement of equipment and materials that meet high performance and durability standards.