Torque and Bolt Tension

Introduction

Torque and bolt tension are fundamental concepts in mechanics and mechanical engineering. Proper torque application ensures that bolts maintain secure joints without damaging components or causing the bolt itself to break.

Basic Concepts

Torque (T): Torque is the rotational force applied to a bolt to ensure it generates sufficient clamping force. It is measured in Newton-meters (Nm).

Bolt Tension (σ): Bolt tension is the internal force that develops within the bolt when torque is applied. It is measured in Pascals (Pa) or equivalent units such as Megapascals (MPa).

Relationship Between Torque and Bolt Tension

The relationship between torque and bolt tension can be expressed using the following formula:

T=k⋅d⋅FtT = k \cdot d \cdot F_tT=k⋅d⋅Ft

Where:

- TTT is the torque (Nm)

- kkk is the friction coefficient

- ddd is the nominal bolt diameter (m)

- FₜF_ₜFₜ is the bolt tension force (N)

Conversion Tables

Table 1: Conversion between Torque and Tension Force for Different Bolt Diameters

| Diameter (mm) | Friction Coefficient (k) | Torque (Nm) | Tension Force (N) |

|---|---|---|---|

| 5 | 0.2 | 5 | 250 |

| 10 | 0.2 | 10 | 500 |

| 15 | 0.2 | 20 | 1000 |

| 20 | 0.2 | 50 | 2500 |

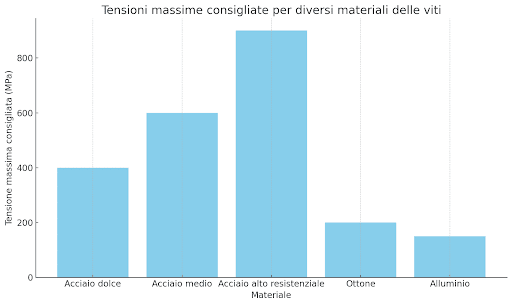

Table 2: Recommended Maximum Tensions for Different Bolt Materials

| Bolt Material | Maximum Tension (MPa) |

|---|---|

| Carbon Steel | 400 |

| Stainless Steel | 700 |

| Titanium | 900 |

Graphs

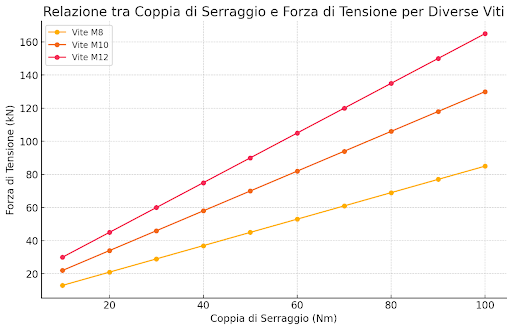

Graph 1: Relationship between torque and tension force for different bolts (M8, M10, and M12).

Graph 2: Recommended maximum tensions for different bolt materials

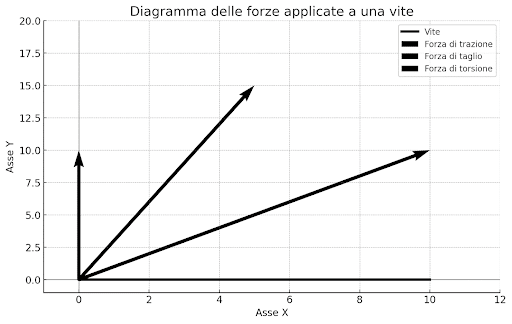

Graph 3: Force diagram applied to a bolt:

- Tensile force: Represented by an upward arrow.

- Shear force: Represented by a horizontal arrow.

- Torsional force:

Represented by a diagonal arrow.

Images

Image:

Example of a dynamometer for torque measurement.

Conclusion

A precise understanding of torque and bolt tension is essential for ensuring the safety and durability of mechanical structures. Using high-quality bolts and fasteners, correctly sized and tightened with the appropriate torque, can prevent catastrophic failures and costly maintenance.

Companies in the mechanical and engineering sectors can benefit from advanced measurement tools and strict quality control to ensure that each bolt is tightened with the required precision. Investing in training and skill development for personnel can further enhance operational efficiency and safety, leading to reduced overall operating costs.

By using our product range—designed with cutting-edge materials and innovative manufacturing technologies—you can ensure superior performance and reliability in every project.