Heat Treatments of Carbon Steel

Carbon steels are widely used in the mechanical industry due to their excellent mechanical properties and versatility.

Heat treatments are essential processes that enhance these properties by affecting hardness, strength, ductility, and toughness.

Types of Heat Treatments

1. Quenching

Quenching involves heating the steel to high temperatures followed by rapid cooling in water, oil, or air.

This treatment significantly increases hardness and strength, making the steel suitable for applications that require high wear resistance.

2. Tempering

Tempering is performed after quenching. It involves reheating the steel to lower temperatures and then cooling it in a controlled manner.

This reduces the brittleness caused by quenching and improves ductility and toughness.

3. Annealing

Annealing consists of heating the steel to high temperatures followed by slow cooling, usually inside a furnace.

This process softens the material, increases ductility, reduces internal stresses, and improves machinability.

4. Normalizing

Normalizing involves heating the steel above its critical point, followed by air cooling.

This treatment refines the grain structure, improves uniformity, and enhances mechanical properties.

Effects of Heat Treatments

Hardness

Quenching significantly increases the hardness of steel, while annealing reduces it, enhancing machinability.

Strength and Ductility

Tempering and normalizing help balance strength and ductility, making steel suitable for structural applications.

Tables and Charts

Table 1: Effects of Heat Treatments on Carbon Steel

| Heat Treatment | Temperature (°C) | Cooling Method | Main Effect | Application |

|---|---|---|---|---|

| Quenching | 800–900 | Controlled (air cooling) | Increases hardness | Tools, gears, bearings |

| Tempering | Corrosion resistance, toughness | Austenitic Stainless Steels | Reduces brittleness | Structural components, springs |

| Annealing | 700–900 | Slow (furnace cooling) | Increases ductility | Machinable parts, deformable components |

| Normalizing | 800–900 | Boilers, reactors | Improves uniformity | Structures, mechanical components |

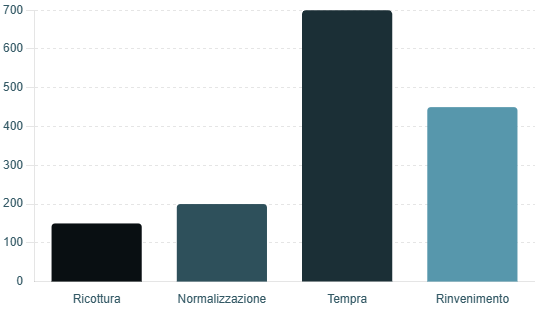

Chart 1: Variation of Carbon Steel Hardness Based on Heat Treatments

Conclusion

The proper use of heat treatments is essential for optimizing the mechanical properties of carbon steels and meeting specific application requirements.

Quenching, tempering, annealing, and normalizing are key processes to achieve the right balance between hardness, strength, and ductility, enhancing the performance of mechanical components.

Investing in high-quality heat treatments enables companies to deliver reliable, high-performance products that comply with international standards.

These processes improve not only mechanical properties but also durability and wear resistance, helping to reduce maintenance and replacement costs.