Machining by chip removal: boring

Introduction

Boring is a finishing machining process used to improve the dimensional accuracy and surface quality of pre-drilled or cast holes. This process is essential for achieving holes with tight tolerances, smooth surfaces, and perfectly cylindrical geometry. Boring is often employed in critical applications where a perfect fit between components is required, such as in engines, hydraulic and pneumatic systems, and various other mechanical industries.

Boring Process

The boring process involves the use of a tool called a reamer, which has multiple cutting edges distributed along its length. This tool rotates inside the pre-existing hole, removing a small amount of material and improving the dimensional accuracy and surface finish of the hole.

Workpiece Preparation

- Description: Before boring, the workpiece is securely fixed on a machine tool, such as a lathe or milling machine. Proper alignment of the initial hole with the reamer axis is essential to avoid misalignment and achieve a perfectly cylindrical hole.

- Applications: Proper workpiece preparation is crucial for obtaining a hole that meets the required specifications in terms of tolerances and surface finish.

Selection of the Reamer

- Description: The reamer is selected based on the hole diameter, workpiece material, and required surface finish. Reamers can be made of high-speed steel (HSS), carbide, or other materials, with varying cutting edge configurations depending on the application.

- Applications: The correct choice of reamer directly affects the quality of the hole and the tool's longevity.

Boring Operation

- Description: During boring, the tool rotates at a relatively low speed and advances slowly along the hole. This movement removes a small amount of material at a time, ensuring a very smooth surface finish and high dimensional accuracy. Machining parameters such as rotation speed and feed rate are adjusted to optimize hole quality.

- Applications: Boring enables the production of holes with tight tolerances and high-quality surface finishes, essential for critical applications.

Quality Control and Finishing

- Description: After boring, the hole is inspected to verify that its dimensions, concentricity, and surface finish meet the required specifications. If necessary, additional finishing operations such as polishing can be performed to further enhance hole quality.

- Applications: Ensures that the final hole meets all the technical specifications required by the project.

Boring Parameters Table

| Reaming Parameter | Description | Impact on Machining |

|---|---|---|

| Spindle Speed (n) | Number of revolutions per minute of the reamer | Affects surface quality and tool life |

| Feed Rate (f) | Feed rate of the tool along the hole | Determines surface roughness and productivity |

| Reamer Material | Material of which the tool is made (e.g., HSS, carbide) | Influences hardness, wear resistance, and cutting ability |

| Lubrication | Use of cutting fluids during reaming | Reduces friction, cools the tool, and improves hole quality |

Applications of Boring

Boring is widely used across various industrial sectors due to its ability to produce holes with high dimensional accuracy and surface quality. Some examples of applications include:

Automotive Industry

- Example: Boring of engine cylinders, valve seats, and other engine components requiring holes with very tight tolerances and high-quality surface finishes to ensure efficiency and durability.

- Advantages: Boring provides perfectly smooth and concentric surfaces, essential for proper engine operation and reduced internal friction.

Aerospace Sector

- Example: Machining of critical structural components, such as bearing housings and joints, where a perfect fit between parts is required. These holes must be manufactured with extremely tight tolerances and excellent finishes to ensure safety and reliability.

- Advantages: Boring allows machining of advanced alloys with extreme precision, improving the quality and safety of aerospace components.

Precision Engineering

- Example: Production of components for measuring instruments, medical devices, and watch parts, where extremely tight tolerances and high-quality surface finishes are required.

- Advantages: Boring ensures holes with precision and surface quality that meet the stringent requirements of precision engineering.

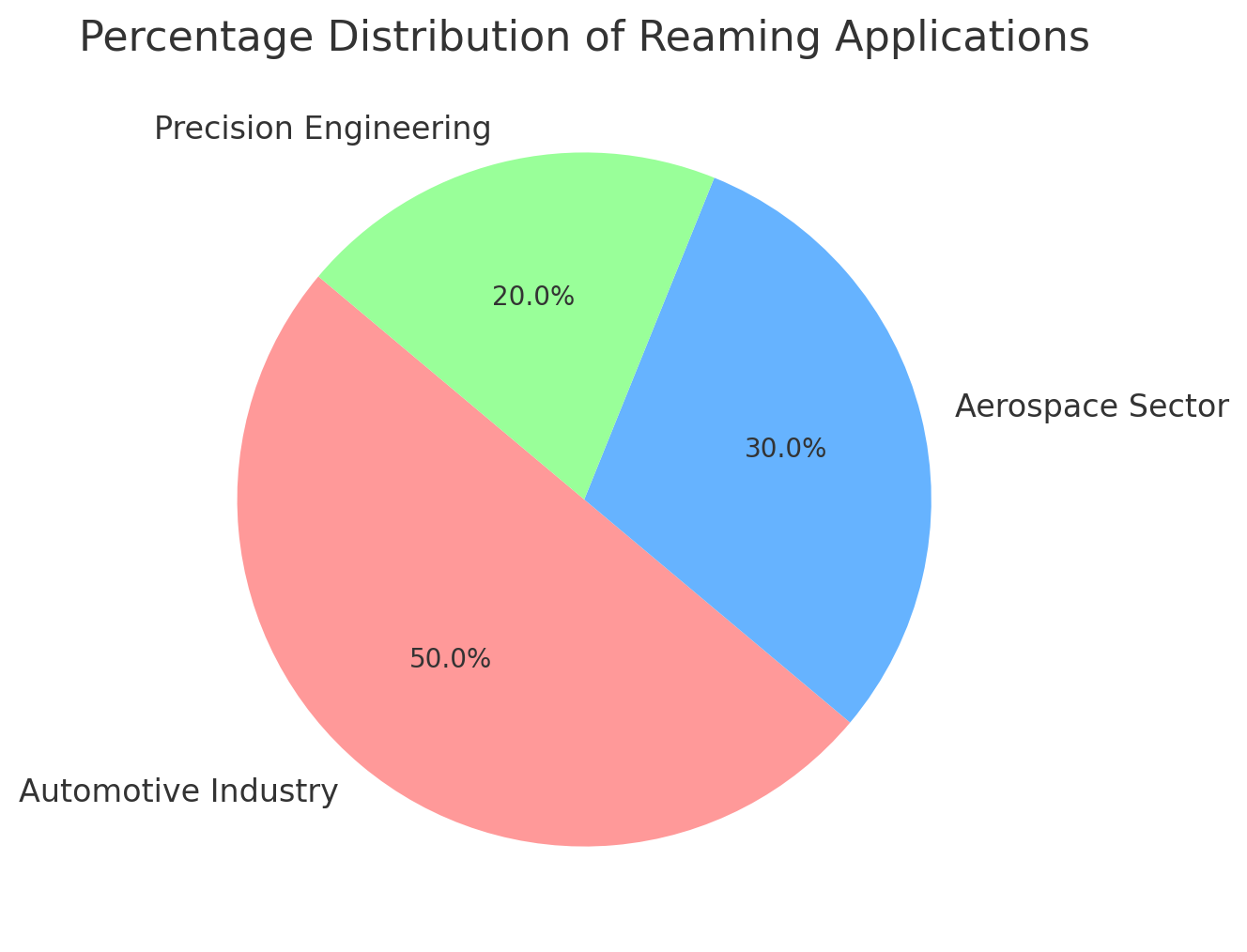

Graph: Distribution of Boring Applications

Below is a graph showing the percentage distribution of common boring applications: This graph highlights how boring is widely used in the automotive, aerospace, and precision engineering sectors, where hole precision and quality are essential.

Advantages and Challenges of Boring

Advantages:

- High Dimensional Accuracy: Boring allows for holes with very tight tolerances, reducing the need for additional machining.

- Excellent Surface Finish: Boring produces a high-quality surface finish, essential for critical applications requiring a perfect fit between components.

- Versatility: It can be used on a wide range of materials, including ferrous metals, non-ferrous metals, and special alloys, making it suitable for multiple industrial applications.

Challenges:

- Tool Wear: Wear of reamers can affect hole quality and increase production costs, requiring careful tool management.

- Chip Removal: Efficient chip management during boring is essential to avoid defects such as scratches or clogging, which can compromise final hole quality.

- Vibration Control: Vibrations during boring can compromise hole quality and workpiece precision, requiring optimized machining strategies.

Commercial Conclusion

Boring is a highly precise and versatile machining technique that is essential for producing critical components in industries such as automotive, aerospace, and precision engineering. While it presents challenges related to tool wear and chip management, its advantages in terms of precision, surface quality, and versatility make it a primary choice for creating holes with tight tolerances and high-quality finishes.