Machining by Chip Removal: Broaching

Introduction

Broaching, also known as spline cutting, is a machining process used to create shaped surfaces such as grooves, teeth, and internal or external profiles on metallic parts. This process is distinguished by the use of a tool called a broach, which has a series of progressively larger teeth that remove material from the workpiece in a single pass. Broaching is highly valued for its ability to produce complex shapes with high precision and surface finish, making it ideal for applications in the automotive, aerospace, and precision mechanics industries.

Broaching Process

The broaching process can be divided into several stages, each of which is crucial to ensuring the quality and precision of the final component. The typical sequence of this process is described below:

Workpiece Preparation

- Description: The workpiece to be machined is securely fixed on the broaching machine. Proper alignment is essential to avoid errors during machining and to achieve the desired profile.

- Applications: Correct preparation of the workpiece is crucial to obtaining the final shape and dimensions within the required tolerances.

Selection and Preparation of the Broach

- Description: The broach is a long and narrow tool with a series of progressively larger teeth. It is selected based on the shape and dimensions of the profile to be obtained. The tool must be carefully prepared to ensure uniform material removal.

- Applications: The choice of the broach is critical for the quality of the profile and the surface finish of the workpiece.

Machining

- Description: During machining, the broach is either pushed or pulled through the workpiece. The broach's teeth gradually remove excess material, forming the desired profile in a single pass. Machining parameters, such as feed speed and applied pressure, must be optimized to prevent defects and ensure the quality of the workpiece.

- Applications: This phase enables the creation of complex profiles with high precision and surface finish, making broaching ideal for mass production of standardized components.

Quality Control and Finishing

- Description: After broaching, the workpiece is inspected to verify compliance with the required dimensional and quality specifications. Additional finishing operations may be necessary to refine the machined surface or correct minor defects.

- Applications: Ensures that the final piece meets the required tolerances and surface quality, guaranteeing the full functionality of the component.

Broaching Parameters Table

| Broaching Parameter | Description | Impact on Machining |

|---|---|---|

| Feed Rate | Speed at which the broach is pushed or pulled through the workpiece | Affects surface quality and tool life |

| Broach Type | Configuration of the broach teeth (straight, helical, etc.) | Determines profile shape and surface finish quality |

| Lubrication | Use of cutting fluids during broaching | Reduces friction, cools the tool, and improves surface quality |

| Workpiece Material | Type of material being machined (steel, aluminum, etc.) | Influences broach selection and process parameters |

Applications of Broaching

Broaching is widely used in various industrial sectors due to its ability to produce complex shapes with high precision and surface quality. Some examples of applications include:

Automotive Industry

- Example: Production of splines for engine shafts, gears, and wheel hubs. These components require precise profiles and smooth surfaces to ensure proper fit and operation.

- Advantages: Broaching enables the creation of complex profiles in a single pass, improving productivity and reducing machining costs.

Aerospace Sector

- Example: Creation of grooves and internal profiles for structural components and turbine engine parts. These components must be highly precise and durable to ensure aircraft safety and efficiency.

- Advantages: Broaching provides perfectly smooth and concentric surfaces, reducing component wear and enhancing longevity.

Precision Mechanics

- Example: Manufacturing of components for measuring instruments, medical devices, and watch parts, where extremely tight tolerances and high-quality surface finishes are required.

- Advantages: Broaching achieves profiles with the precision and surface quality that meet the stringent requirements of precision mechanics.

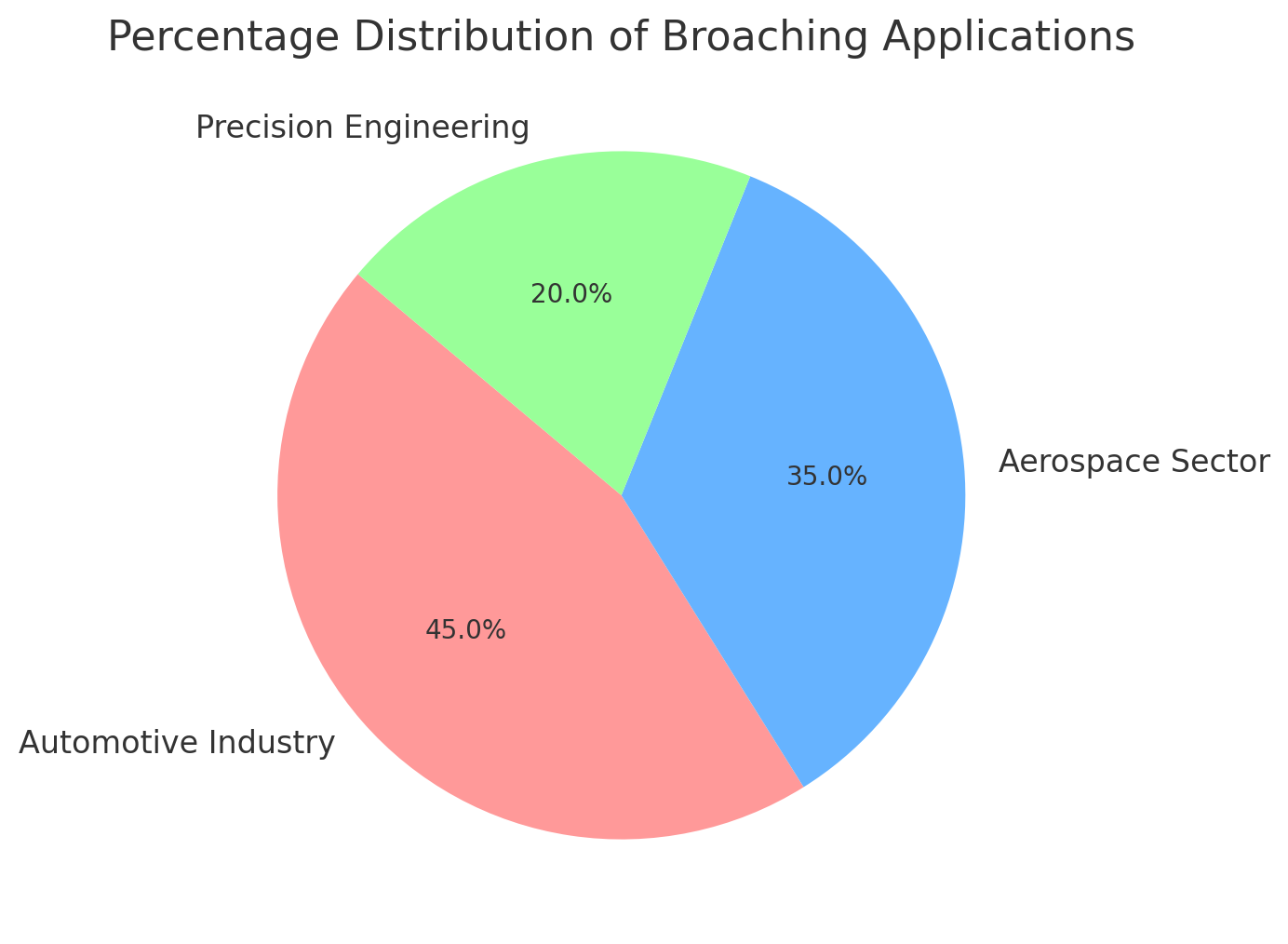

Graph: Distribution of Broaching Applications

Below is a graph showing the percentage distribution of common broaching applications: This graph highlights how broaching is extensively used in the automotive, aerospace, and precision mechanics sectors, where precision and profile quality are essential.

Advantages and Challenges of Broaching

Advantages:

- High Precision and Repeatability: Broaching allows for the creation of complex profiles with very tight tolerances, ensuring consistent quality in mass production.

- Production Efficiency: Broaching enables the machining of complex profiles in a single pass, reducing processing times and improving productivity.

- Excellent Surface Finish: The broaching process produces smooth, high-quality surfaces, minimizing the need for additional finishing operations.

Challenges:

- Tooling Costs: Manufacturing and maintaining broaches can be expensive, especially for applications requiring complex or customized profiles.

- Geometric Limitations: Broaching is limited in machining shapes with intricate geometries or variable cross-sections, necessitating the use of complementary techniques.

- Tool Wear: Broaches can wear out quickly, especially when machining hard or abrasive materials, increasing production costs and reducing tool lifespan.

Commercial Conclusion

Broaching is an extremely precise and efficient chip removal machining technique, ideal for the mass production of components with complex profiles and high-quality surfaces. Although it presents challenges related to tooling costs and geometric limitations, its advantages in terms of precision, repeatability, and surface quality make it a preferred choice for industries such as automotive, aerospace, and precision mechanics.