Machining by Chip Removal: Sintering

Introduction

Sintering is a manufacturing process that combines metallic or ceramic powders through heating to a temperature below the melting point of the involved materials. This method allows the production of components with complex geometries, optimal mechanical properties, and high density. Although sintering is not a traditional chip removal process, it can be integrated with subsequent machining operations to achieve the required tolerances and surface finishes. This makes sintering an essential technique in the production of high-precision components, widely used in the automotive, aerospace, and precision mechanics industries.

Sintering Process

The sintering process can be divided into several phases, each crucial to ensuring the quality and precision of the final component. Below is a typical sequence of this process:

Powder Preparation

- Description: The process begins with the preparation of a mixture of metallic or ceramic powders. These powders are selected based on the desired properties of the final product and may be mixed with additives to improve sintering.

- Applications: Accurate selection of powders is essential to achieving the required mechanical and physical properties in the finished product.

Compaction

- Description: The prepared powder is placed into a mold and compressed under high pressure to form a "green" piece—a preliminary component with a defined shape but still fragile. The density of the green piece is crucial in determining the quality of the sintered part.

- Applications: Compaction ensures that the piece maintains its shape during sintering and that the density is uniform.

Sintering

- Description: The green piece is heated at a controlled temperature, below the melting point of the powders, in a furnace. During sintering, the powder particles bond together, reducing porosity and increasing the density of the part. This process enhances the mechanical properties of the component.

- Applications: Sintering enables the production of components with high mechanical strength, hardness, and other desired properties, such as corrosion resistance and thermal conductivity.

Secondary Machining Operations

- Description: After sintering, the component may undergo additional machining operations such as milling, drilling, or turning to meet the required dimensional tolerances and improve surface finish.

- Applications: These operations are often necessary to ensure that the sintered part meets the technical specifications required for final assembly.

Table of Sintering Process Properties

| Process Step | Description | Impact on Component Quality |

|---|---|---|

| Powder Preparation | Selection and mixing of powders | Determines the mechanical and physical properties of the sintered part |

| Compaction | Compression of the powder to form the green compact | Affects the density and final shape of the component |

| Sintering | Controlled heating to bond the particles | Improves the strength, hardness, and density of the part |

| Secondary Machining Operations | Operations such as milling, drilling, or turning | Allows achieving the desired tolerances and surface finish |

Applications of Sintering

Sintering is used across various industrial sectors due to its ability to produce components with superior mechanical properties and complex geometries. Some examples include:

Automotive Industry

- Example: Production of components such as gears, bearings, and structural parts requiring high wear resistance and dimensional precision. These components must be durable and reliable to ensure proper vehicle operation.

- Advantages: Sintering allows the production of components with complex geometries and high mechanical properties while reducing production costs.

Aerospace Sector

- Example: Manufacturing of lightweight yet strong structural components, such as engine parts and avionics supports. These components must maintain excellent performance under extreme conditions.

- Advantages: Sintering enables materials to achieve high specific strength, reducing the overall weight of components and improving flight efficiency.

Precision Mechanics

- Example: Production of components for watches, measuring instruments, and medical devices, where extremely tight tolerances and specific mechanical properties are required.

- Advantages: Sintering allows the manufacturing of parts with high precision and high-quality surface finishes, suitable for high-precision applications.

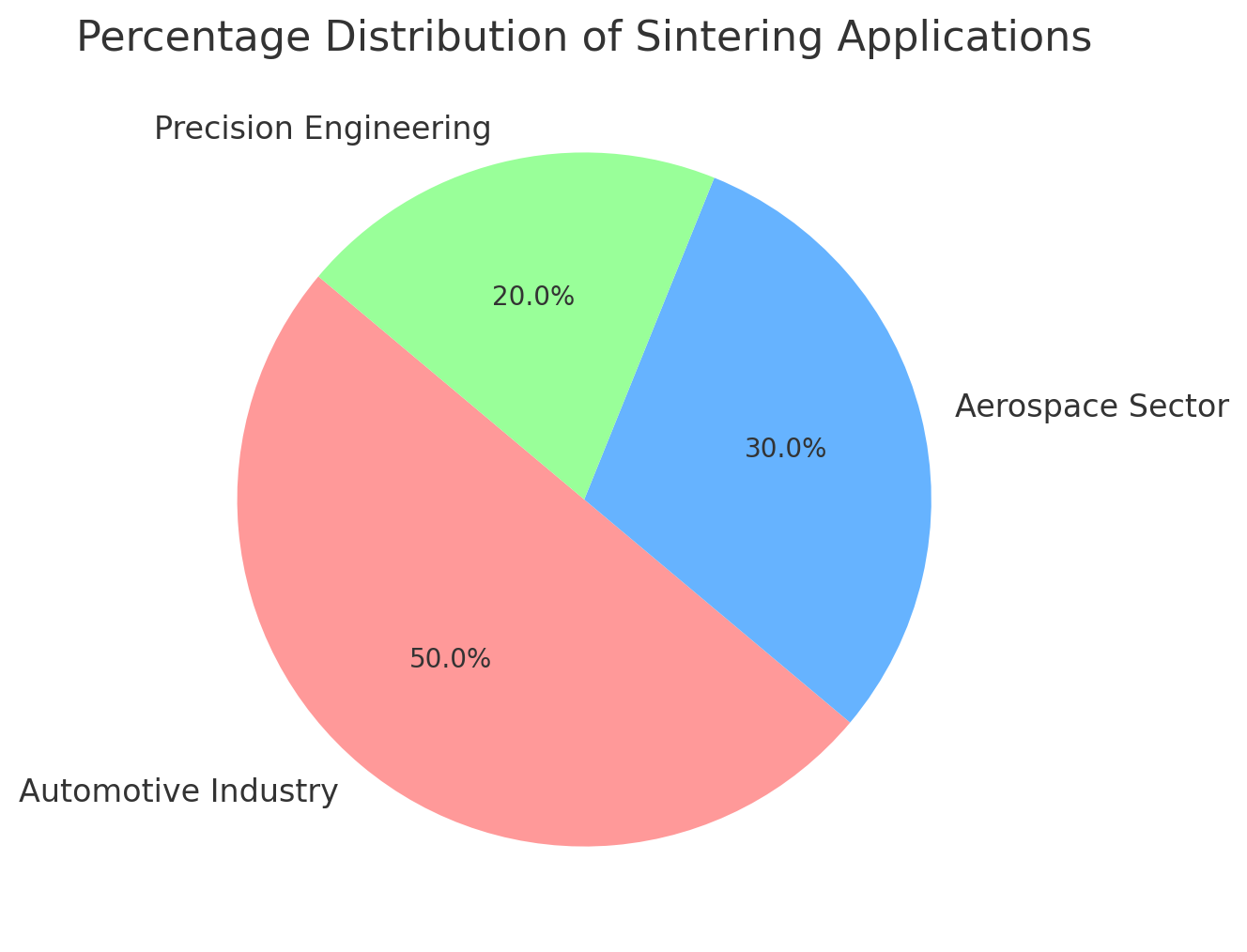

Graph: Distribution of Sintering Applications

Below is a graph showing the percentage distribution of common sintering applications: This graph highlights how sintering is widely used in the automotive, aerospace, and precision mechanics sectors, where material quality and mechanical properties are essential.

Advantages and Challenges of Sintering

Advantages:

- Production of Complex Geometries: Sintering enables the manufacturing of components with shapes that would be difficult or expensive to achieve with other machining processes.

- Material Efficiency: Since sintering uses powders, the process is highly efficient in material utilization, minimizing waste.

- High Density and Mechanical Properties: Sintered components can achieve high density, which enhances mechanical properties such as tensile strength, hardness, and wear resistance.

Challenges:

- Porosity Control: Residual porosity can negatively affect the mechanical properties of the sintered part, requiring strict process control.

- Tooling Costs: Sintering requires specialized equipment, such as molds and furnaces, which can be expensive, especially for small-scale production.

- Material Limitations: Not all materials are suitable for sintering, and some alloys may require special treatments or combined processes to achieve desired properties.

Commercial Conclusion

Sintering is a versatile and efficient machining technique capable of producing components with superior mechanical properties and complex geometries. While it presents challenges related to porosity control and tooling costs, the advantages in terms of precision, material efficiency, and the ability to produce complex shapes make it a strategic choice for industries such as automotive, aerospace, and precision mechanics.