Assembly Types

Introduction

Assembly is a crucial phase in the production process of any mechanical product. Various types of assembly can be used, depending on the specific needs of the product and the characteristics of the components. In this document, we will explore the main types of assembly used in the mechanical industry: manual assembly, automated assembly, and hybrid assembly. Each method has its own advantages, disadvantages, and specific applications.

Manual Assembly

Manual assembly involves the use of skilled workers to join the components of a product. This method is commonly used for small-scale production or for products that require a high degree of customization.

Advantages:

- Flexibility in the process

- Suitable for small batches and customized products

- Low initial investment cost

Disadvantages:

- Low productivity

- High labor costs

- Potential for human error

Table: Comparison of Manual and Automated Assembly Costs

| Type of Assembly | Initial Cost | Labor Cost | Productivity |

|---|---|---|---|

| Manual | Low | High | Low |

| Automated | High | Low | High |

Automated Assembly

Automated assembly uses machinery and robots to join components. It is suitable for large-scale production and standardized products.

Advantages:

- High productivity

- Fewer errors

- Reduced labor costs

Disadvantages:

- High initial investment cost

- Low flexibility

- Expensive maintenance and upgrades

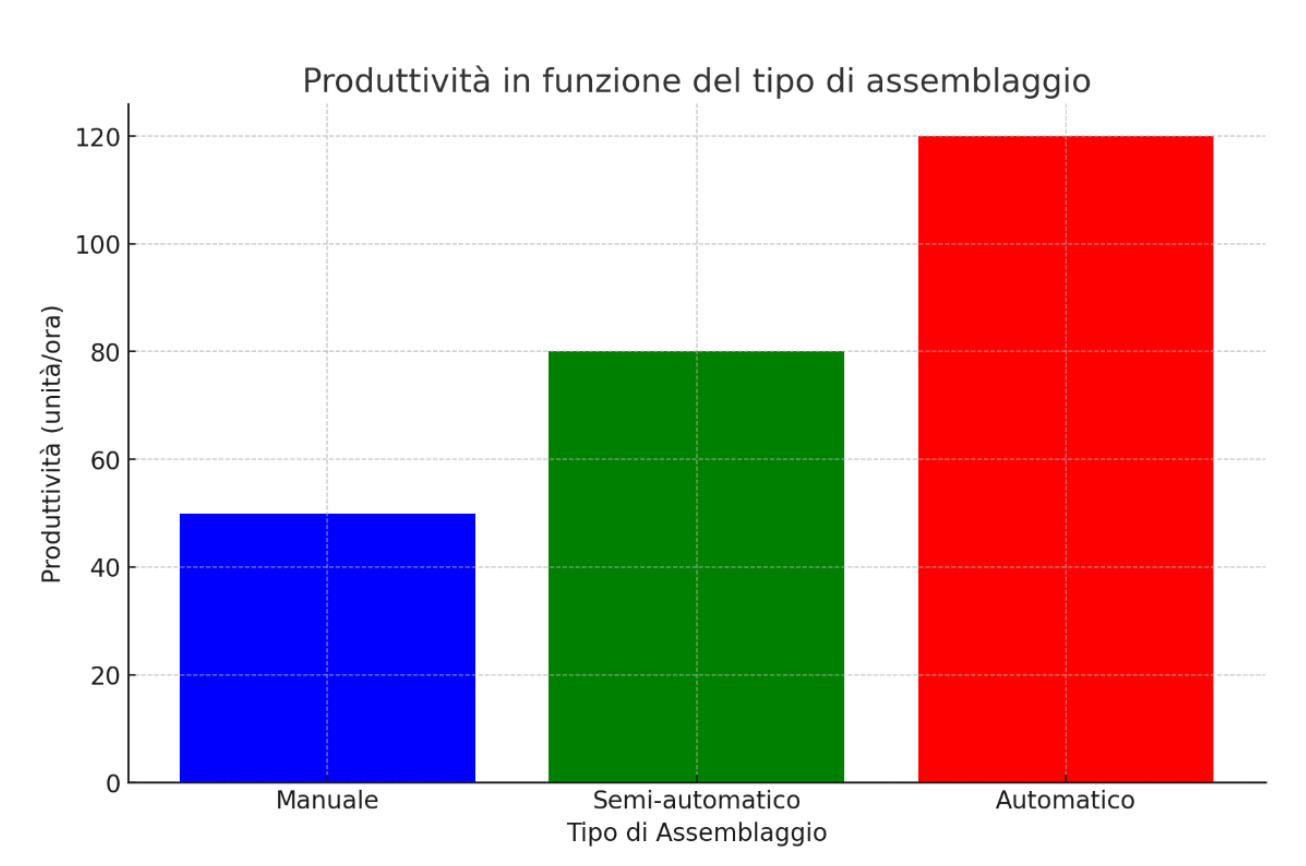

Graph: Productivity vs. Assembly Type

Hybrid Assembly

Hybrid assembly combines elements of both manual and automated assembly. This method is often used to balance the advantages and disadvantages of the two methods.

Advantages:

- Improved flexibility

- Good balance between productivity and costs

- Suitable for medium-scale production

Disadvantages:

- Moderate initial investment

- Complexity in coordinating manual and automated operations

Image: Example of a Hybrid Assembly Line

Final Considerations

In conclusion, the choice of assembly type depends on specific production needs, product characteristics, and available resources. Manual assembly is ideal for small batches and customized products, while automated assembly is more suitable for large-scale production. Hybrid assembly offers a balance between the two, combining the flexibility of manual labor with the efficiency of automation.

Conclusion

When deciding which assembly method to adopt, it's important to consider not only costs and productivity but also the added value that each method can offer to the final customer. Offering products assembled with precision and consistency can increase customer satisfaction and brand trust. Investing in advanced assembly technologies allows a company to respond quickly to market demands and improve overall product quality. Ultimately, a careful analysis and selection of the assembly method not only optimizes production costs but can also elevate the product's market perception, thus contributing to the company's commercial success.