Galvanic Metallic Coatings: Current Designation of Electrolytic Zinc Plating Treatments

Introduction

Electrolytic zinc plating is one of the most widely used galvanic coating processes, applied to improve the corrosion resistance of metallic components and to provide an aesthetically pleasing finish. This treatment involves the deposition of a thin layer of zinc on a metallic surface through an electrochemical process. In recent years, the evolution of technologies and regulations has led to the standardization and precise designation of various electrolytic zinc plating treatments, each with specific characteristics in terms of corrosion resistance, coating thickness, and industrial applications.

Main Types of Electrolytic Zinc Plating Treatments

Below is an overview of the main types of electrolytic zinc plating treatments, with their current designations:

Electrolytic Zinc Plating with Cr3+ Passivation (Trivalent Chromate)

Description: This treatment uses a trivalent chromium (Cr3+)-based passivant, offering good corrosion protection and complying with environmental regulations, avoiding the use of hexavalent chromium (Cr6+), known for its toxicity.

Applications: Widely used in the automotive, electromechanical, and construction industries, especially for components that require good corrosion resistance and compliance with environmental standards.

Advantages: Good corrosion resistance, eco-compatibility, and compliance with international regulations (e.g., RoHS, REACH).

Electrolytic Zinc Plating with Cr6+ Passivation (Hexavalent Chromate)

Description: This treatment uses a hexavalent chromium (Cr6+)-based passivant, providing excellent protection against corrosion. However, due to its toxicity, Cr6+ use is in decline and strictly regulated.

Applications: Still used in certain industrial sectors where extremely high corrosion resistance is required, but it is progressively being replaced by more environmentally friendly alternatives.

Advantages: Excellent corrosion resistance, but poses toxicity issues and non-compliance with many environmental regulations.

Electrolytic Zinc Plating with Chromium-Free Passivation

Description: This treatment uses chromium-free passivants, providing moderate corrosion protection. They are often applied where higher eco-compatibility and reduced environmental impact are required.

Applications: Mainly used in industries where environmental compliance is critical, such as electronics and telecommunications.

Advantages: Maximum eco-compatibility, though offering lower corrosion protection compared to chromium-based treatments.

Electrolytic Zinc Plating with Organic Sealing

Description: In this treatment, after zinc plating, an organic sealant is applied to further enhance corrosion resistance and coating durability.

Applications: Used in industries requiring extremely high corrosion resistance, such as automotive, aerospace, and infrastructure exposed to harsh weather conditions.

Advantages: Significantly increases coating durability and corrosion protection in challenging environments.

Summary Table of Main Types of Electrolytic Zinc Plating

| Type of Galvanization | Passivation Used | Corrosion Resistance | Environmental Compliance | Main Applications |

|---|---|---|---|---|

| Galvanization with Cr3+ Passivation | Trivalent Chromium (Cr3+) | Good | High | Automotive, Electromechanical |

| Galvanization with Cr6+ Passivation | Hexavalent Chromium (Cr6+) | Excellent | Low | Critical Industrial Applications |

| Chromium-free Galvanization | Non-Chromate Passivation | Moderate | Maximum | Electronics, Telecommunications |

| Galvanization with Organic Sealing | Organic Passivation | Very High | Variable | Automotive, Aerospace, Infrastructure |

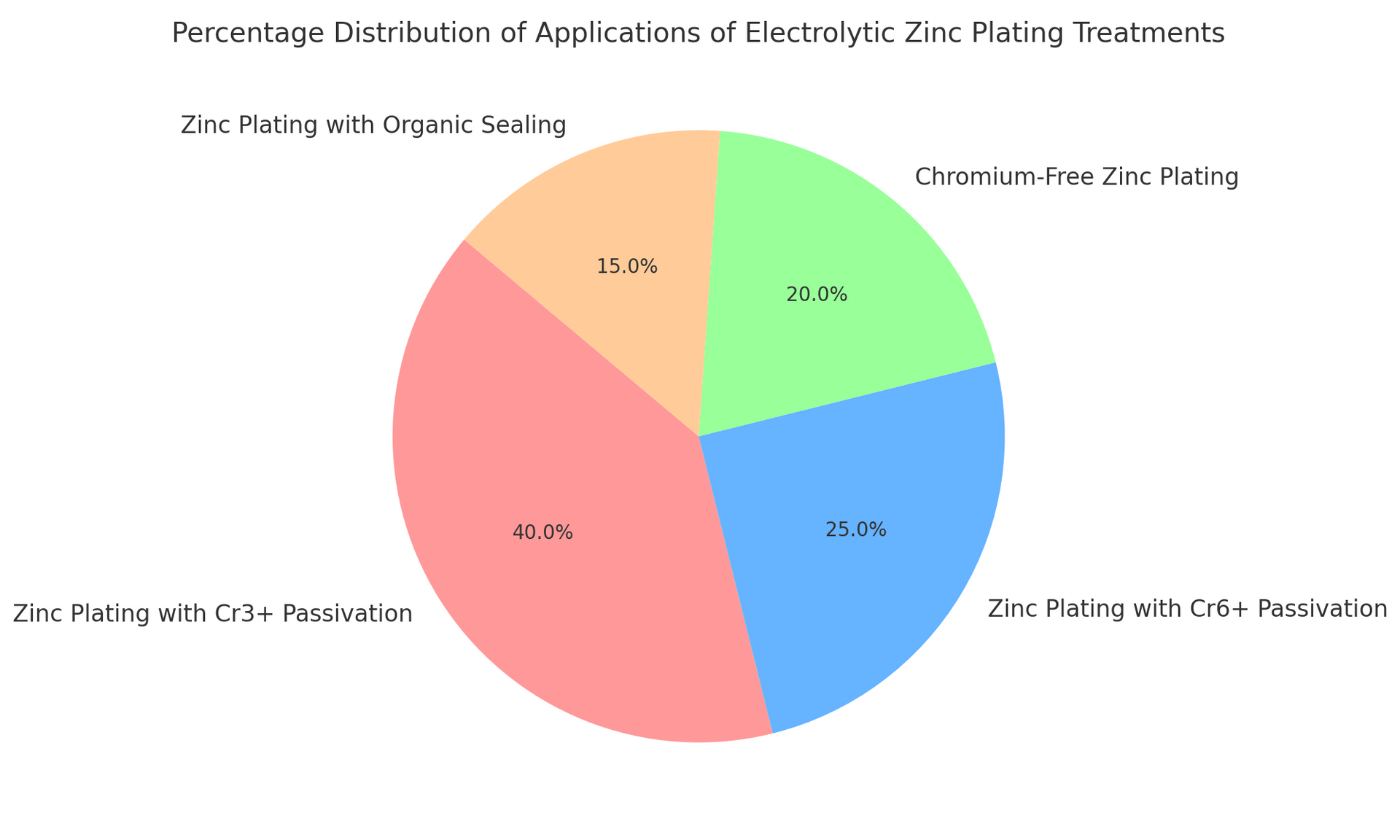

Chart: Distribution of Applications of Electrolytic Zinc Plating

Below is a chart showing the percentage distribution of common applications of various electrolytic zinc plating treatments:

This chart highlights how different zinc plating treatments are used across various industrial sectors, with particular emphasis on automotive and construction applications, where corrosion protection and environmental compliance are essential.

Advantages and Challenges of Electrolytic Zinc Plating

Advantages:

Effective Corrosion Protection: Electrolytic zinc plating provides excellent protection against corrosion, extending the service life of metallic components.

Broad Application Versatility: Can be applied to a wide range of metallic components, with various finishing and corrosion resistance options, adapting to the specific needs of different industries.

Improved Aesthetics: Provides components with a shiny or matte finish, enhancing aesthetic appeal and increasing the perceived value of finished products.

Challenges:

Environmental Management: Treatments using hexavalent chromium (Cr6+) are highly effective but pose significant environmental and health issues, making the transition to greener alternatives necessary.

Process Quality Control: Electrolytic zinc plating requires precise control of process parameters, such as current density, bath composition, and immersion time, to ensure a uniform, high-quality coating.

Limited Resistance in Extreme Conditions: While effective, electrolytic zinc plating may require additional treatments (such as passivation or sealing) to provide adequate protection in highly corrosive environments.

Commercial Conclusion

Electrolytic zinc plating, with its various designations and treatments, represents an essential solution for protecting metallic components against corrosion, while also providing aesthetic and durability benefits. Although the industry must address challenges related to environmental management and process quality control, the overall benefits make this process a preferred choice in many sectors, including automotive, electromechanical, and construction.

Investing in electrolytic zinc plating technology, especially in its more modern and eco-friendly versions, enables companies to offer high-quality products that comply with international regulations and meet the highest customer expectations. This not only enhances market competitiveness but also contributes to a more sustainable industrial future.