How a threaded joint works

Introduction

A threaded joint is a mechanical connection system commonly used in various industrial sectors to securely and detachably join two or more components. This type of joint utilizes threads—helical grooves—to achieve the coupling between components. Threaded joints are essential for constructing machines, structures, and other systems where solidity and ease of assembly and disassembly are required.

Working Principle

Threaded joints function by creating a clamping force generated by the screwing of the threads. This clamping force keeps the components firmly together and allows them to resist external stresses. Below is a detailed description of the process:

- External and Internal Threading:

- External Threading: The protruding part, such as in a bolt.

- Internal Threading: The recessed part, such as in a nut.

- Screwing Process:

- The screwing process involves aligning the external and internal threads by rotating the bolt (or screw) into the nut.

- This rotation generates an axial force that joins the components.

- Clamping Force

- The axial force is converted into a clamping force due to the thread pitch.

- This force is essential to keep the joint stable and resistant to vibrations.

Types of Threaded Joints

Threaded joints can vary based on different factors, such as the type of threading, material, and specific application. Some of the main types include:

- Joints with Screws:

- Used to join components that require a detachable assembly.

- Examples: Hex-head screws, flat-head screws.

- Joints with Bolts and Nuts:

- Provide greater strength compared to simple screws.

- Examples: Hex-head screws, flat-head screws.

- Joints with Threaded Studs:

- Used in applications where precise alignment is needed.

- Examples: Guide studs, positioning studs.

Comparison Table

| Type of Joint | Tensile Strength | Ease of Assembly | Common Applications |

|---|---|---|---|

| Screws | Medium | High | Electronics, Furniture |

| Bolts and Nuts | High | Medium | Metal Structures, Machinery |

| Threaded Studs | High | Low | Precision Machinery, Molds |

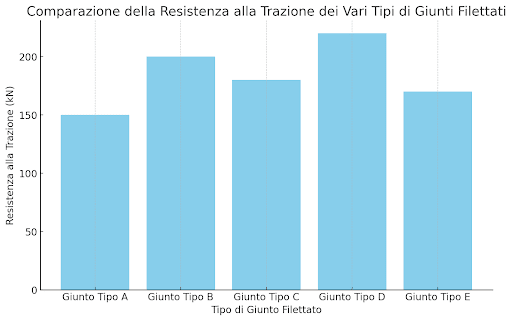

Resistance Graph

Figure 1: Comparison of tensile strength for different types of threaded joints.

Images of Threaded Joints

- Screws – 2. Bolts – 3. Nuts – 4. Threaded Studs

Technical Considerations

Selecting the appropriate threaded joint depends on several factors, including the applied load, operating environment, and material of the components being joined. Some key technical aspects to consider include:

- Material: Threaded joints can be made from various materials, including steel, stainless steel, brass, and plastic. The choice of material affects corrosion resistance, hardness, and mechanical strength.

- Surface Treatments: To increase durability and corrosion resistance, threaded joints can undergo surface treatments such as galvanization, nickel plating, and phosphating.

- Tolerances and Precision:

Dimensional tolerances of threads are crucial to ensure proper fit and adequate clamping force. ISO and ANSI standards provide guidelines for thread tolerances and specifications.

Conclusion

In conclusion, threaded joints are critical components in many industrial and commercial applications. Understanding how they work and their characteristics is essential to ensure the reliability and safety of mechanical structures. Choosing the right threaded joint can significantly improve product lifespan and performance, reduce maintenance costs, and enhance the overall quality of projects.