Preload in fastening systems

Introduction

Preload is a force intentionally applied to a mechanical component during assembly to ensure a solid and stable connection. In the context of fastening systems, preload refers to the initial tension imparted to bolts, screws, and other fasteners to prevent loosening due to vibrations, temperature variations, and variable loads. This document explores the concept of preload, application methods, and its impact on the performance of mechanical joints.

Working Principle

Preload is essential for ensuring the safety and stability of threaded joints. Without adequate preload, components can experience relative movement, leading to premature wear, loss of structural integrity, and, in extreme cases, catastrophic failures. Preload is generally applied through:

- Torque Wrench Tightening:

- Allows controlled clamping force application.

- Ensures precision and repeatability.

- Strain Gauge Tightening:

- Uses sensors to measure bolt deformation.

- Provides a direct measurement of clamping force.

- Hydraulic Tightening Techniques:

- Uses pressurized fluids to apply high forces.

- Suitable for applications requiring very high clamping force.

Importance of Preload

Proper preload is crucial for ensuring the performance of threaded joints. Here are some of its key functions:

- Prevention of Loosening: Preload helps keep components tightly joined, preventing loosening due to vibrations and load cycles.

- Load Distribution: Uniform preload ensures that the load is evenly distributed among components, reducing stress concentration risks.

- Seal Maintenance: In applications requiring a leak-proof seal, such as hydraulic systems, preload helps maintain joint integrity.

Comparison Table

| Preload Method | Precision | Applicability | Advantages | Disadvantages |

|---|---|---|---|---|

| Torque Wrench | High | Universal | Easy to use | Requires calibration |

| Strain Gauge | Very high | Industrial | Direct measurement | Expensive, complex |

| Hydraulic Tightening | Very high | High tension | High force application | Requires costly equipment |

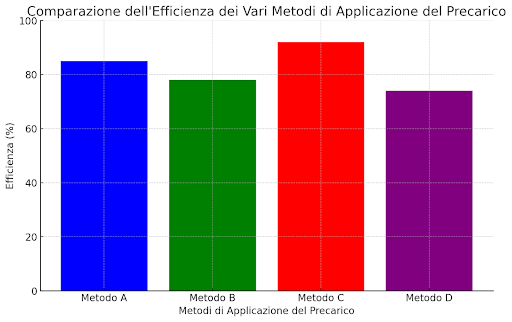

Preload Efficiency Graph

Figure 1: Comparison of efficiency across different preload application methods.

- Method A: 85%

- Method B: 78%

- Method C: 92%

- Method D: 74%

Preload Application Images

1.Application with Torque Wrench:

2.Hydraulic Tightening Techniques:

Technical Considerations

The correct application of preload depends on various factors, including:

- Component Material: The deformation and elastic properties of the material influence the amount of preload that can be applied without damaging the component.

- Bolt Size: Larger bolts require higher preload to achieve the same axial tension.

- Environmental Conditions:

Temperature variations can affect bolt tension due to thermal expansion and contraction.

Conclusion

Understanding and correctly applying preload is essential for designing and maintaining reliable mechanical structures. A well-preloaded joint can significantly enhance system durability and safety, reducing maintenance costs and downtime. Investing in high-quality tightening equipment and techniques ensures that threaded joints maintain their integrity over time.

The precision and reliability of threaded joints directly impact the final product quality and operational safety. Collaborating with trusted suppliers and properly training personnel on the use of tightening equipment can be a step forward in achieving the high standards required by the market. In conclusion, preload is not just a technical matter but a strategic element in ensuring the quality and reliability of mechanical products.