HV Assembly: Bolt + Nut + 2 Washers with CE Certification for Controlled Tightening Joints (UNI EN 14399-4 / 14399-6)

Introduction

In the field of construction and infrastructure, the safety and durability of structures largely depend on the quality of structural joints. The HV bolting system, consisting of a bolt, nut, and two washers, is designed to ensure maximum performance in controlled tightening joints. This system complies with UNI EN 14399-4 and UNI EN 14399-6 standards, which define the requirements for high-strength bolted connections in steel structures, ensuring that these components meet the safety and quality standards required by European directives, including CE certification.

Components of the HV System

The HV system is made up of three main elements: bolt, nut, and two washers. Each of these components plays a crucial role in ensuring the functionality and safety of the joint.

HV Bolt

- Description: The HV bolt is designed to withstand high tensile and shear loads. It is made of high-strength steel and has a metric thread that ensures uniform and secure tightening.

Specific Characteristics:

- Strength class: 10.9, guaranteeing a minimum tensile strength of 1040 MPa.

- Surface treatment: Often hot-dip galvanized to improve corrosion resistance.

- Applications: Mainly used in structural connections of bridges, high-rise buildings, and infrastructures requiring a high degree of safety.

HV Nut

- Description: The HV nut is paired with the HV bolt to ensure a secure fit and uniform load distribution. It is manufactured with hardness compatible with the bolt to prevent deformation and ensure reliable tightening.

Specific Characteristics:

- Strength class: 10, compatible with the bolt strength class.

- Shape: Hexagonal, allowing torque application with standard tools.

- Surface treatment: Like the bolt, often hot-dip galvanized for durability.

HV Washers

Questo è il testo del paragrafo. Fai clic o premi il Button Gestisci testo per modificare il carattere, il colore, le dimensioni, il formato e altro ancora. Per impostare gli stili di paragrafo e titolo del sito web, vai al tema del sito web.

Table: Technical Characteristics of the HV System

| Component | Material | Strength Class | Surface Treatment | Main Applications |

|---|---|---|---|---|

| HV Bolt | High-strength steel | 10.9 | Hot-dip galvanization | Bridges, buildings, infrastructures |

| HV Nut | High-strength steel | 10 | Hot-dip galvanization | Structural joints |

| HV Washer | High-strength steel | - | Hot-dip galvanization | Uniform load distribution |

Reference Standards and CE Certification

The HV system complies with the following European standards that define requirements for high-strength bolted joints:

UNI EN 14399-4 - High-strength structural bolting assemblies for preloading – Part 4: System HV – Hexagon bolt and nut assemblies:

This standard specifies the requirements for HV hexagon bolts and nuts used in preloaded structural connections. It covers dimensions, strength classes, and surface treatments, ensuring the components are suitable for critical structural applications.

UNI EN 14399-6 - High-strength structural bolting assemblies for preloading – Part 6: Plain washers:

This standard specifies the requirements for plain washers used in HV structural bolting systems. Washers must ensure uniform load distribution and withstand the high pressures generated during tightening.

Installation Process

Correct installation of the HV system is essential to ensure the safety and integrity of structures. The process includes the following stages:

Joint Preparation

Description: Before installation, contact surfaces must be clean and free from contaminants. Proper hole alignment is crucial for safe installation.

Techniques:

- Check alignment and component compatibility.

- Clean with solvents to remove oils or contaminants.

Tightening

Description: Tightening is performed with a torque wrench, following a predefined sequence to ensure uniform load distribution. Controlled tightening is crucial to prevent joint relaxation and ensure structural stability.

Critical Parameters:

- Torque: Must be applied according to project specifications.

- Tightening sequence: Often a cross-pattern to evenly distribute forces.

Verification and Quality Control

Description: After tightening, all joints must be checked to ensure proper tightening and no loosening. Checks may include residual torque measurement and visual inspection.

Control Tools:

- Torque wrench to verify torque.

- Visual inspection to check correct positioning of bolts, nuts, and washers.

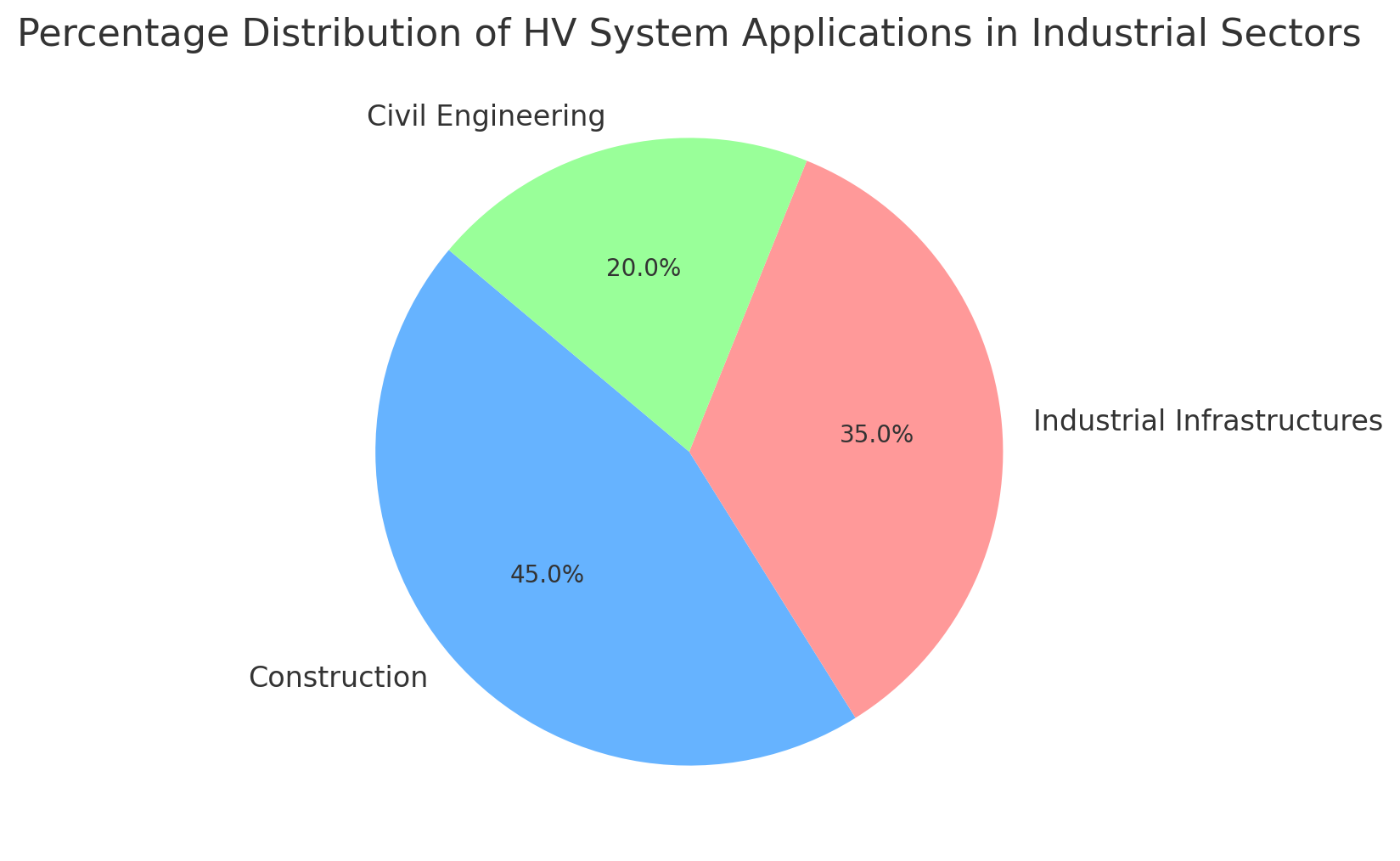

Chart: Distribution of HV System Applications

Below is a chart showing the percentage distribution of common HV system applications in various industrial sectors:

This chart highlights how the HV system is widely used in construction, industrial infrastructures, and civil engineering projects, where mechanical strength and safety are priorities.

Business Conclusion

The HV bolting system, certified according to UNI EN 14399-4 and UNI EN 14399-6, represents a reliable and safe solution for high-strength structural joints. This system is designed to meet the highest standards of safety and durability, ensuring structural stability even under severe operating conditions.

For companies involved in critical infrastructure construction, choosing the HV system with CE certification is an investment in project quality and safety.