SB Assembly with Hexagon Head Bolt and Hexagon Nut CE Certified (UNI EN 15048)

Introduction

The SB assembly, consisting of a hexagon head bolt and a hexagon nut, is designed for structural applications that require non-preloaded joints, in compliance with UNI EN 15048. This fastening system is commonly used in construction, infrastructure, and civil engineering projects, where safety and reliability are crucial. CE certification ensures that these components meet European directives on quality and safety, delivering excellent performance across a wide range of operating conditions.

Features of the SB System

The SB assembly is characterized by the combination of a hexagon bolt and a hexagon nut, designed to be used together in joints that do not require preloading. These components are manufactured to precise specifications to ensure compatibility, strength, and ease of installation.

Hexagon Head Bolt

Description: The hexagon head bolt is one of the most common and versatile fasteners used in construction. It is designed to distribute the load evenly during tightening, thanks to its wide contact surface.

Specific Features:

- Strength Class: SB bolts are generally available in strength classes 4.6, 8.8, and 10.9, depending on application needs.

- Material: Carbon steel or alloy steel, with surface treatments to resist corrosion.

- Surface Treatment: Often hot-dip galvanized or painted to improve durability and resistance to atmospheric agents.

Applications: Hexagon head bolts are used in steel structures, building construction, bridges, and other infrastructure where secure and reliable connections are required.

Hexagon Nut

Description: The hexagon nut is designed to be used with the hexagon bolt, providing a strong and secure connection. Its hexagonal shape allows easy application of torque with standard tools.

Specific Features:

- Strength Class: Compatible with the bolts used, generally the same strength classes (4.6, 8.8, 10.9).

- Material: Made of carbon steel or alloy steel, with treatments to resist corrosion.

- Surface Treatment: Like the bolt, the nut is often hot-dip galvanized or painted to enhance resistance to corrosive agents.

Applications: Used together with hexagon bolts for non-preloaded structural joints, mainly in construction and infrastructure.

Table: Technical Characteristics of the SB System

| Component | Material | Strength Class | Surface Treatment | Main Applications |

|---|---|---|---|---|

| Hex Head Bolt | Carbon or alloy steel | 4.6, 8.8, 10.9 | Hot-dip galvanization, painting | Construction, infrastructures, bridges |

| Hex Nut | Carbon or alloy steel | 4.6, 8.8, 10.9 | Hot-dip galvanization, painting | Structural joints |

Reference Standard: UNI EN 15048

The SB assembly complies with UNI EN 15048, which regulates non-preloaded structural bolted joints. This standard specifies the requirements for performance, mechanical properties, and testing methods for bolting systems used in steel construction.

Standard Requirements

Mechanical Properties: The standard specifies the mechanical properties that bolts and nuts must have, including tensile strength and hardness.

Dimensions and Tolerances: Bolt and nut dimensions must meet tight tolerances to ensure safe assembly and even load distribution.

Surface Treatments: The standard requires components to be treated for corrosion resistance, with particular attention to outdoor applications.

CE Certification

The CE certification ensures that products comply with the essential requirements of European directives, providing quality and safety in every application. The CE mark is a mandatory requirement for marketing products within the European market.

Installation Process

Correct installation of the SB assembly is essential to ensure the integrity and safety of structures. The installation process includes:

Joint Preparation

Description: Before installation, ensure all contact surfaces are clean and free from contaminants. Surfaces must be properly aligned for safe assembly.

Techniques:

- Check alignment of components.

- Clean with appropriate solvents to remove any oils or grease.

Tightening

Description: Tightening of the bolt and nut must be carried out using a torque wrench to ensure that the torque applied complies with the project’s technical specifications.

Critical Parameters:

- Tightening Torque: Must be applied uniformly to avoid joint relaxation.

- Tightening Sequence: An appropriate tightening sequence must be followed to evenly distribute forces in the joint.

Quality Control

Description: After tightening, the joint must be checked to ensure correct installation, verifying residual torque and the absence of looseness.

Control Tools:

- Torque wrench for torque verification.

- Visual inspection to check proper installation of bolt and nut.

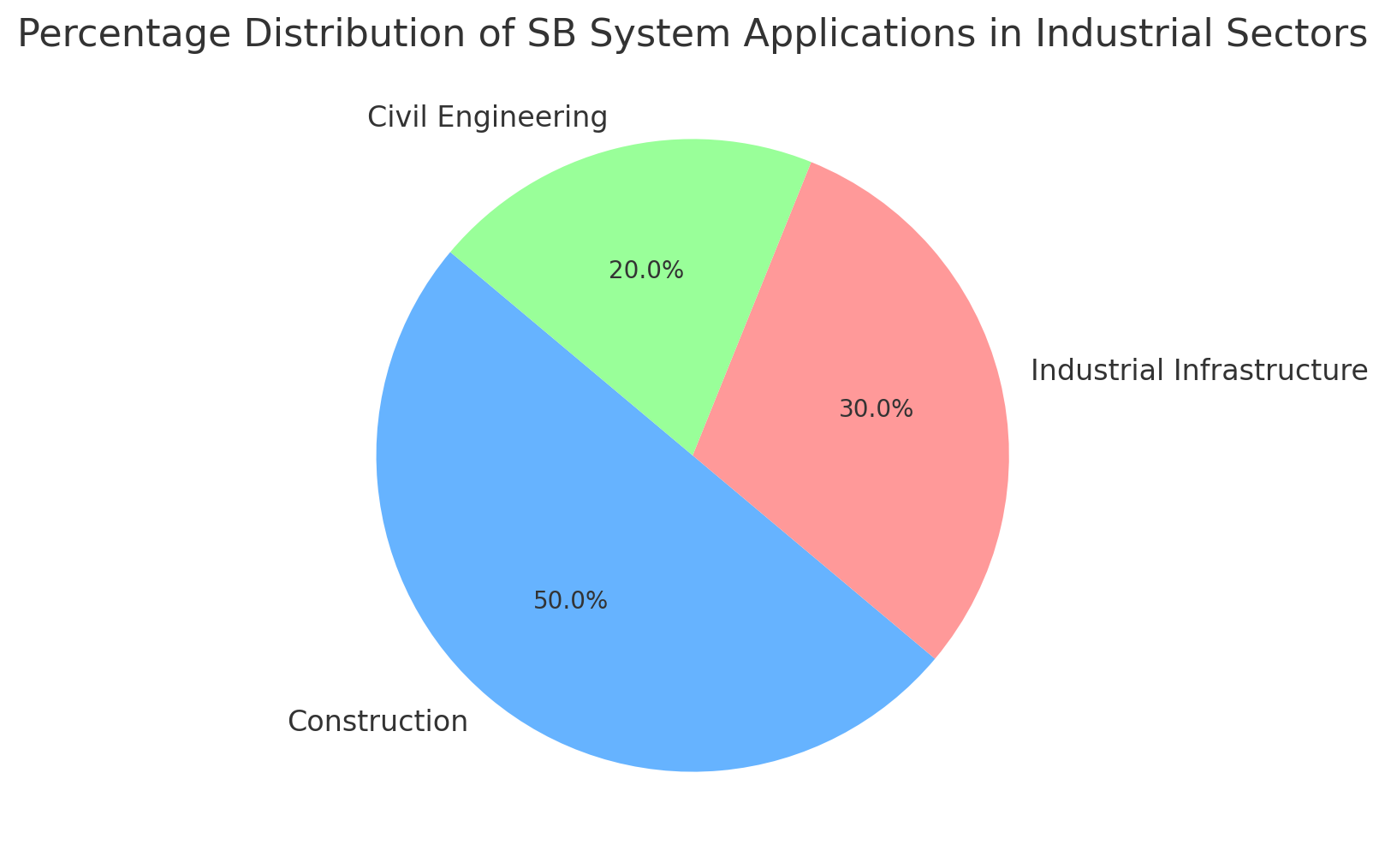

Chart: Distribution of SB System Applications

Below is a chart showing the percentage distribution of common applications of the SB system across various industrial sectors:

This chart highlights how the SB system is primarily used in construction, industrial infrastructure, and civil engineering projects, where joint quality and safety are of paramount importance.

Commercial Conclusion

The SB assembly, CE certified according to UNI EN 15048, represents a safe and reliable choice for non-preloaded structural joints. Designed to meet the highest requirements in terms of strength, durability, and safety, this system is ideal for a wide range of industrial and construction applications.