MACHINING BY CHIP REMOVAL: DRILLING

Introduction

Drilling is one of the fundamental techniques in machining by chip removal, used to create cylindrical holes in solid materials. This process is essential in many industrial applications, as holes are required for component assembly, fluid passage creation, and the insertion of fasteners. Drilling can be performed on various materials, including metals, alloys, plastics, and composites, using a wide range of specialized tools.

Drilling Process

The drilling process consists of several stages, each crucial to obtaining a quality hole with the required dimensions and tolerances. Below is a typical sequence of the drilling process:

1. Workpiece Preparation

- Description: The workpiece to be drilled is securely fixed on a table or vise of the machine. It is essential to ensure that the piece is well-centered and clamped to prevent movement during machining.

- Applications: This phase is critical for obtaining precise holes and preventing errors such as hole deviation or tool breakage.

2. Tool Selection

- Description: The drilling tool, usually a twist drill, is selected based on the required hole diameter, the workpiece material, and the drilling depth. The tool must be sharp and of appropriate quality for the material to be machined.

- Applications: Proper tool selection directly affects hole quality and tool lifespan.

3. Drilling

- Description: The tool, rotating at high speed, is fed into the workpiece to remove material in the form of chips and create the hole. Machining parameters such as cutting speed, feed rate, and lubrication must be precisely adjusted.

- Applications: This phase allows obtaining the hole with the desired depth and diameter, paying particular attention to precision and internal finish.

4. Quality Control and Finishing

- Description: After drilling, the hole is inspected to verify dimensions, concentricity, and internal finish. If necessary, operations such as reaming or countersinking can be performed to further improve hole quality.

- Applications: Ensures that the hole meets all project specifications, ensuring compatibility with other components.

Drilling Parameters Table

| Drilling Parameter | Description | Impact on Machining |

|---|---|---|

| Cutting Speed (Vc) | Speed at which the drill contacts the workpiece | Determines surface quality and tool life |

| Feed Rate (f) | Tool advancement speed per workpiece revolution | Affects surface roughness and productivity |

| Drill Point Angle | Angle at the tip of the drilling tool | Influences cutting ability and chip shape |

| Lubrication | Use of cutting fluids during drilling | Reduces friction, cools the tool, and improves hole quality |

Applications of Drilling

Drilling is widely used across various industrial sectors due to its versatility and ability to create precise holes with different geometries. Some examples of applications include:

1. Automotive Industry

- Example: Creating holes for bolts, pins, and fluid passages in critical components such as engine blocks, cylinder heads, and frames. These holes must meet tight tolerances and offer high mechanical strength.

- Advantages: Drilling enables the production of precise components, ensuring proper assembly and vehicle functionality.

2. Aerospace Sector

- Example: Drilling structural components and engine parts, where weight reduction must be achieved without compromising strength. The holes must be extremely precise to ensure safety and efficiency.

- Advantages: Allows working with advanced materials and special alloys with high precision, ensuring the quality and safety of aerospace components.

3. Precision Mechanics

- Example: Producing holes in measuring instruments, watches, and medical devices, where very tight tolerances and high surface quality are required.

- Advantages: Drilling enables the creation of highly precise holes, essential for the proper functioning of complex devices.

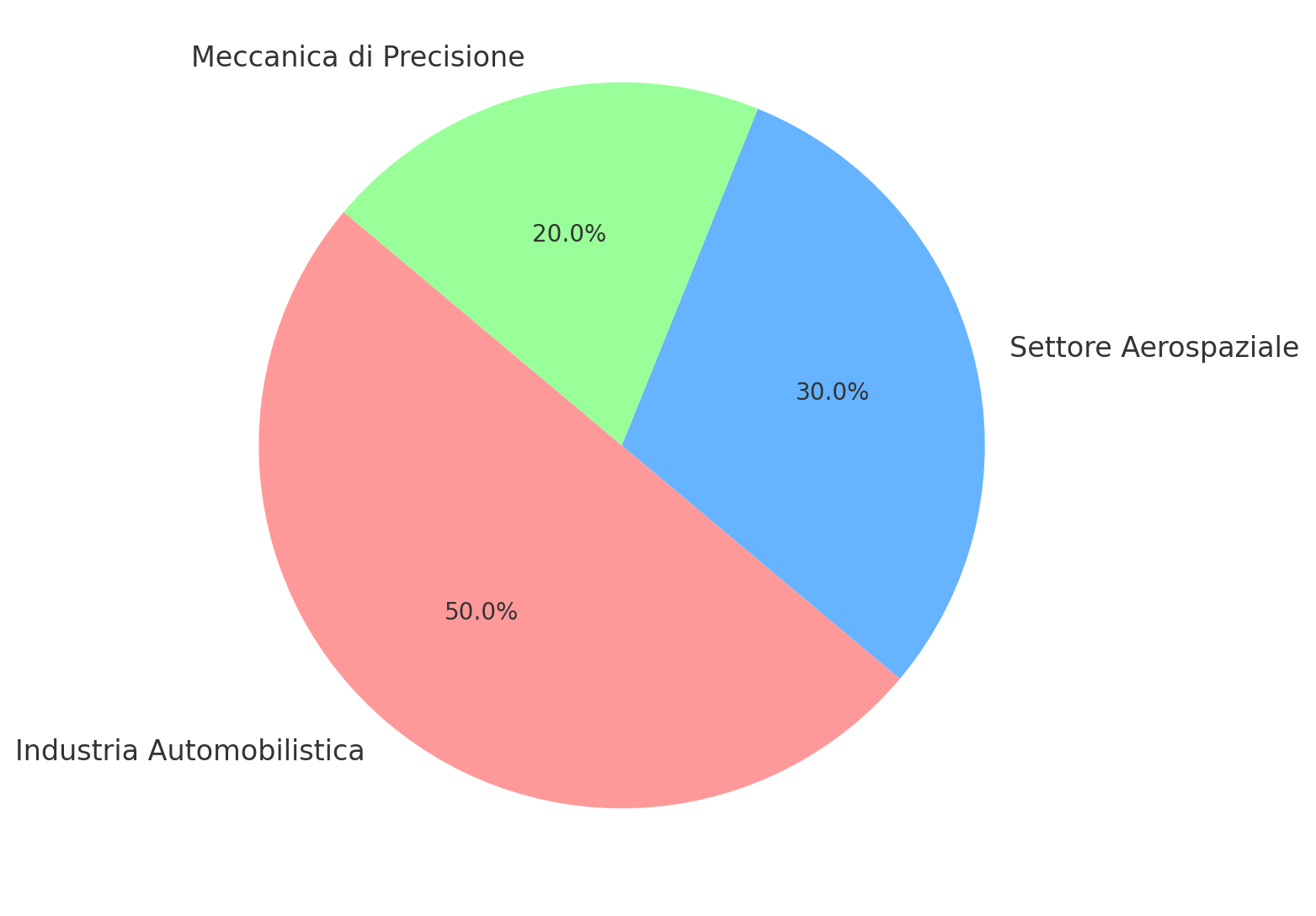

Graph: Distribution of Drilling Applications

Below is a graph showing the percentage distribution of common drilling applications: This graph highlights how drilling is widely used in the automotive, aerospace, and precision mechanics sectors, where hole precision and quality are essential.

Vantaggi e Sfide della Foratura

Vantaggi:

- Versatilità del Processo: La foratura può creare fori di diverse dimensioni e profondità in un'ampia gamma di materiali, dai metalli ferrosi e non ferrosi alle plastiche e ai compositi.

- Elevata Precisione e Ripetibilità: Il processo di foratura può essere altamente preciso, garantendo tolleranze strette e un'elevata ripetibilità, essenziale per la produzione di massa.

- Adattabilità a Operazioni Complesse: La foratura può essere combinata con altre operazioni, come la svasatura e l'alesatura, per ottenere fori con geometrie complesse e finiture superficiali di alta qualità.

Sfide:

- Usura dell'Utensile: L'usura della punta da trapano è una sfida comune che può influire sulla qualità del foro e aumentare i costi operativi.

- Gestione dei Trucioli: La rimozione dei trucioli è fondamentale per evitare difetti nel foro, come graffi o intasamenti, che possono compromettere la qualità finale.

- Controllo delle Vibrazioni: Le vibrazioni durante la foratura possono causare errori di allineamento e problemi di finitura, richiedendo un'attenta selezione dei parametri di lavorazione.

Conclusione Commerciale

La foratura è una delle tecniche di lavorazione più fondamentali e versatili, essenziale per la produzione di componenti di alta precisione in industrie chiave come l'automotive, l'aerospaziale e la meccanica di precisione. Nonostante le sfide legate all'usura degli utensili e alla gestione dei trucioli, i vantaggi in termini di precisione, versatilità e adattabilità a varie applicazioni rendono la foratura una scelta primaria per la fabbricazione di componenti critici.