MECHANICAL PROPERTIES OF METRIC THREADED BOLTS AND STUDS ACCORDING TO IS UNI EN ISO 898-1:2013

Introduction

The IS UNI EN ISO 898-1:2013 standard specifies the mechanical properties of metric threaded bolts and studs made of carbon steel and alloy steel. This standard covers a wide range of strength classes, determining the requirements for properties such as tensile strength, hardness, and resilience.

Classification of Bolts

Bolts and studs are classified based on their strength class, which is indicated by a pair of numbers. The first number represents 1/10 of the minimum tensile strength in MPa, while the second number represents 1/10 of the ratio between tensile strength and yield strength.

Strength Class Tables

| Strength Class | Tensile Strength (MPa) | Yield Strength (MPa) |

|---|---|---|

| 4.6 | 400 | 240 |

| 5.6 | 500 | 300 |

| 8.8 | 800 | 640 |

| 10.9 | 1000 | 900 |

| 12.9 | 1200 | 1080 |

Mechanical Properties of Bolts

| Property | Class 4.6 | Class 5.6 | Class 8.8 | Class 10.9 | Class 12.9 |

|---|---|---|---|---|---|

| Tensile Strength (MPa) | 400 | 500 | 800 | 1000 | 1200 |

| Yield Strength (MPa) | 240 | 300 | 640 | 900 | 1080 |

| Elongation (%) | 22 | 20 | 12 | 9 | 8 |

| Hardness (HV) | 130-180 | 155-220 | 255-335 | 320-380 | 385-445 |

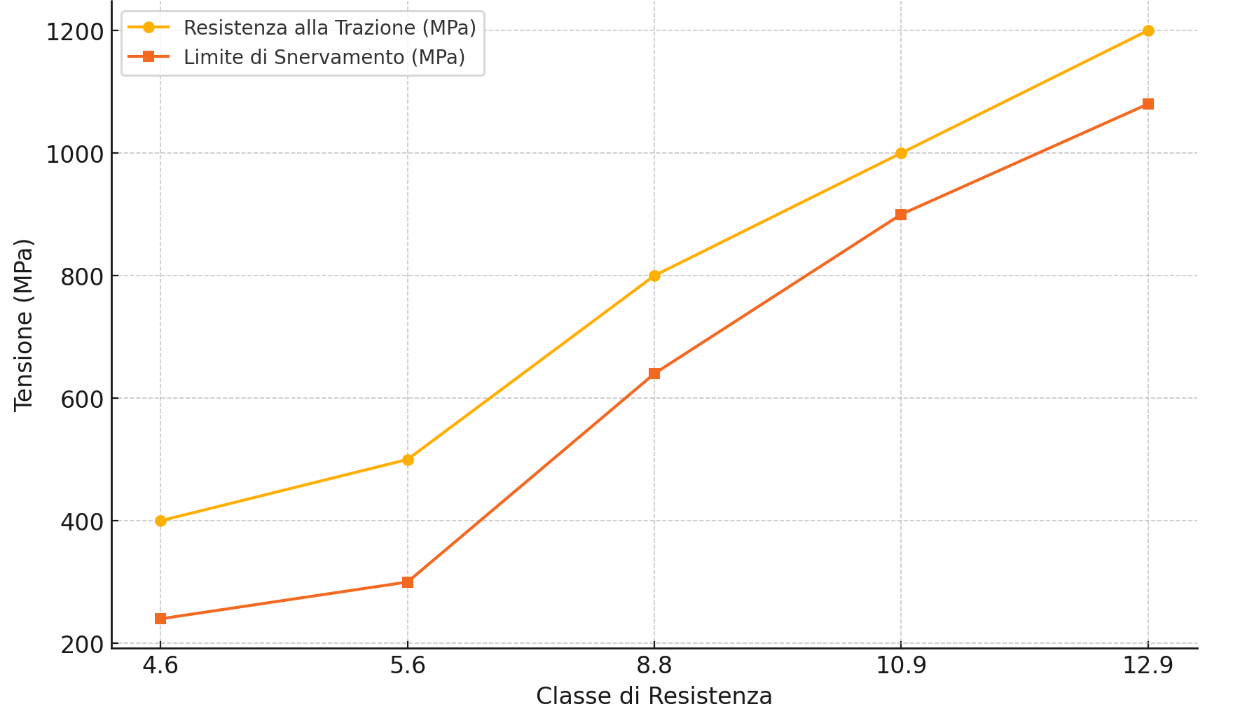

Graph: Tensile Strength vs Yield Strength

The graph belowe shows the relationship between tensile strength and yield strength for the different strength classes of bolts.

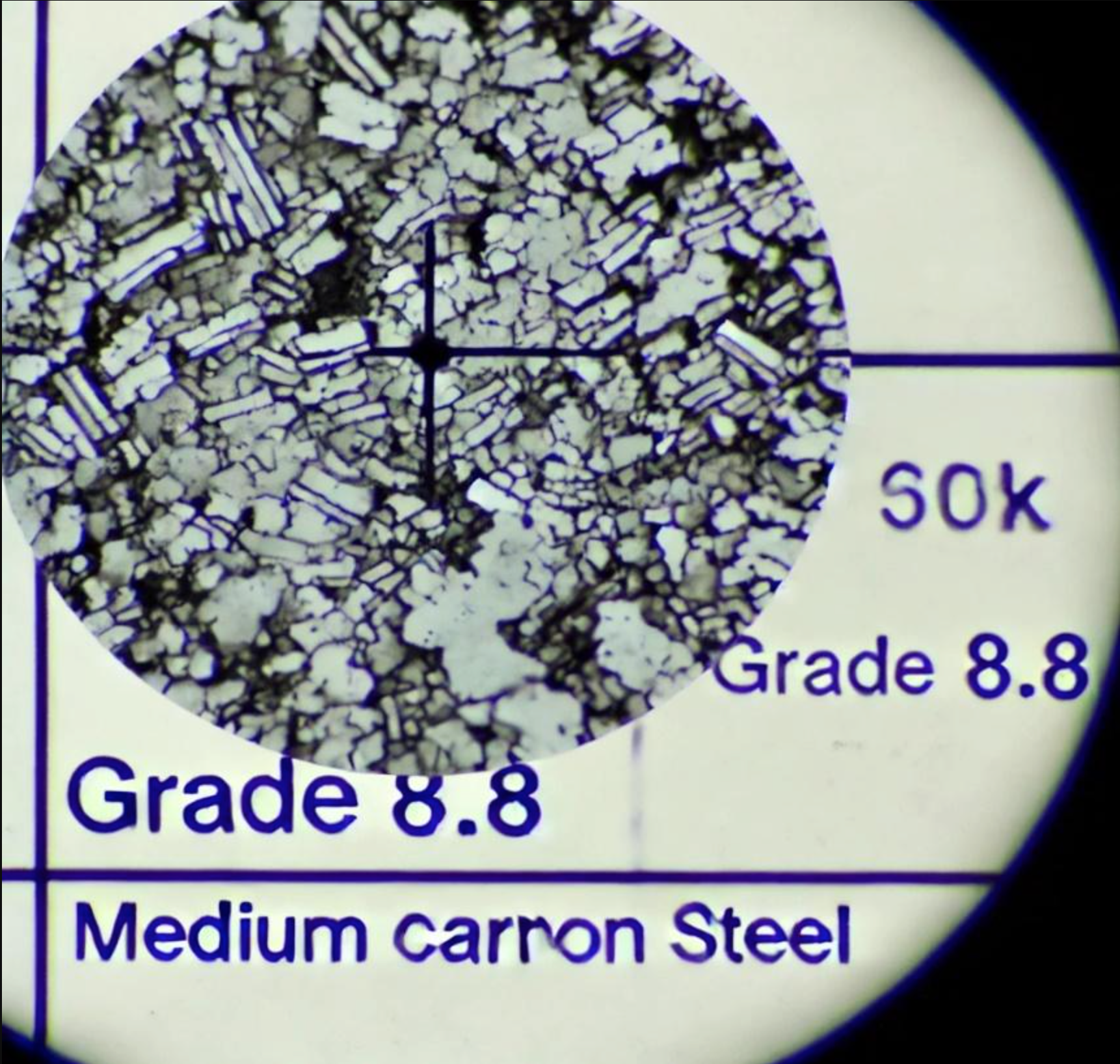

Microstructure Images

The following image shows the typical microstructure of a Class 8.8 bolt:

Applications of Metric Threaded Bolts

Metric threaded bolts and studs are used in a wide range of industrial applications, including:

- Automotive Industry: Used for assembling engine components, bodywork, and transmission systems.

- Construction: Used for fastening steel structures, bridges, and infrastructure.

- Industrial Machinery: Used in the assembly of machine tools, agricultural equipment, and industrial plants.

- Electronics: Used for fastening electronic components, electrical panels, and devices.

Surface Treatments

Bolts can undergo various surface treatments to improve their properties and increase their lifespan. These treatments include:

- Zinc Plating: Application of a zinc coating to improve corrosion resistance.

- Organic Coatings: Application of paints or polymer coatings for corrosion protection and aesthetic enhancement.

- Heat Treatments: Hardening and tempering to increase hardness and mechanical strength.

Conclusion

Metric threaded bolts and studs compliant with the IS UNI EN ISO 898-1:2013 standard represent an excellent choice for companies seeking reliable, durable fastening solutions that meet international standards. Their wide range of strength classes makes them suitable for various industrial applications, from automotive to construction.

Collaborating with experienced and reliable suppliers is essential to ensure the procurement of materials that meet strict quality and performance standards. Relying on certified products according to the IS UNI EN ISO 898-1:2013 standard ensures compliance with required technical specifications and maximum safety in critical applications.