MACHINING BY CHIP REMOVAL: MILLING

Introduction

Milling is one of the most versatile techniques in chip removal mechanical processing, used to create flat surfaces, grooves, complex profiles, and pockets on a wide variety of materials. This process relies on the use of a rotating multi-cutting tool, called a milling cutter, which removes material from the workpiece while it moves along different axes. Thanks to its ability to machine complex surfaces and achieve tight tolerances, milling is widely used in industries such as automotive, aerospace, precision mechanics, and mold manufacturing.

Milling Process

The milling process includes several key phases, each essential for achieving components with the required dimensional and finishing characteristics. Below is the typical sequence of the milling process:

1. Workpiece Preparation

- Description: The workpiece is securely fixed to the machine table. Proper centering and clamping of the workpiece are essential to avoid vibrations and ensure precision during machining.

- Applications: This phase is crucial for achieving precise surfaces and preventing errors such as workpiece deviation during processing.

2. Tool Selection and Preparation

- Description: The milling tool is selected based on the workpiece material and the required machining type (roughing, finishing, profiling). Tool preparation includes sharpening and mounting on the machine.

- Applications: The appropriate tool selection directly affects the quality of the machined surface and the tool’s lifespan.

3. Machining

- Description: During milling, the tool rotates while the workpiece moves along the X, Y, and Z axes of the machine, removing material to achieve the desired shape. Machining parameters such as cutting speed, feed rate, and depth of cut are adjusted to optimize quality and productivity.

- Applications: This phase allows for obtaining components with the required geometry and dimensions, including flat surfaces, grooves, pockets, and complex profiles.

4. Quality Control and Finishing

- Description: Once machining is complete, the workpiece undergoes dimensional and surface checks to ensure it meets the specified tolerances. If necessary, further finishing operations such as grinding can be performed to enhance quality.

- Applications: Ensures that the final component meets all the technical specifications required by the project.

Milling Parameters Table

| Drilling Parameter | Description | Impact on Machining |

|---|---|---|

| Cutting Speed (Vc) | Speed at which the drill contacts the workpiece | Determines surface quality and tool life |

| Feed Rate (f) | Tool advancement speed per workpiece revolution | Affects surface roughness and productivity |

| Drill Point Angle | Angle at the tip of the drilling tool | Influences cutting ability and chip shape |

| Lubrication | Use of cutting fluids during drilling | Reduces friction, cools the tool, and improves hole quality |

Milling Applications

Milling is used in a wide range of industrial sectors due to its versatility and ability to produce components with complex geometries and high precision. Some application examples include:

1. Automotive Industry

- Example: Milling of components such as engine blocks, cylinder heads, gearbox housings, and engine mounts. These components require high dimensional precision and surface finishing to ensure proper vehicle functionality and reliability.

- Advantages: Milling enables the production of precise surfaces and adherence to required tolerances, essential for assembly and component functionality.

2. Aerospace Sector

- Example: Machining of lightweight structural components such as spars, crossbeams, and panels in aluminum and titanium alloys. These components must be strong yet lightweight to ensure aircraft efficiency and safety.

- Advantages: Milling allows for machining advanced materials with tight tolerances, improving the quality and efficiency of aerospace components.

3. Precision Mechanics

- Example: Production of components for measuring instruments, medical devices, and watch parts, where extremely tight tolerances and high-quality surface finishes are required.

- Advantages: Milling enables the creation of components with extreme precision, meeting the stringent requirements of precision mechanics.

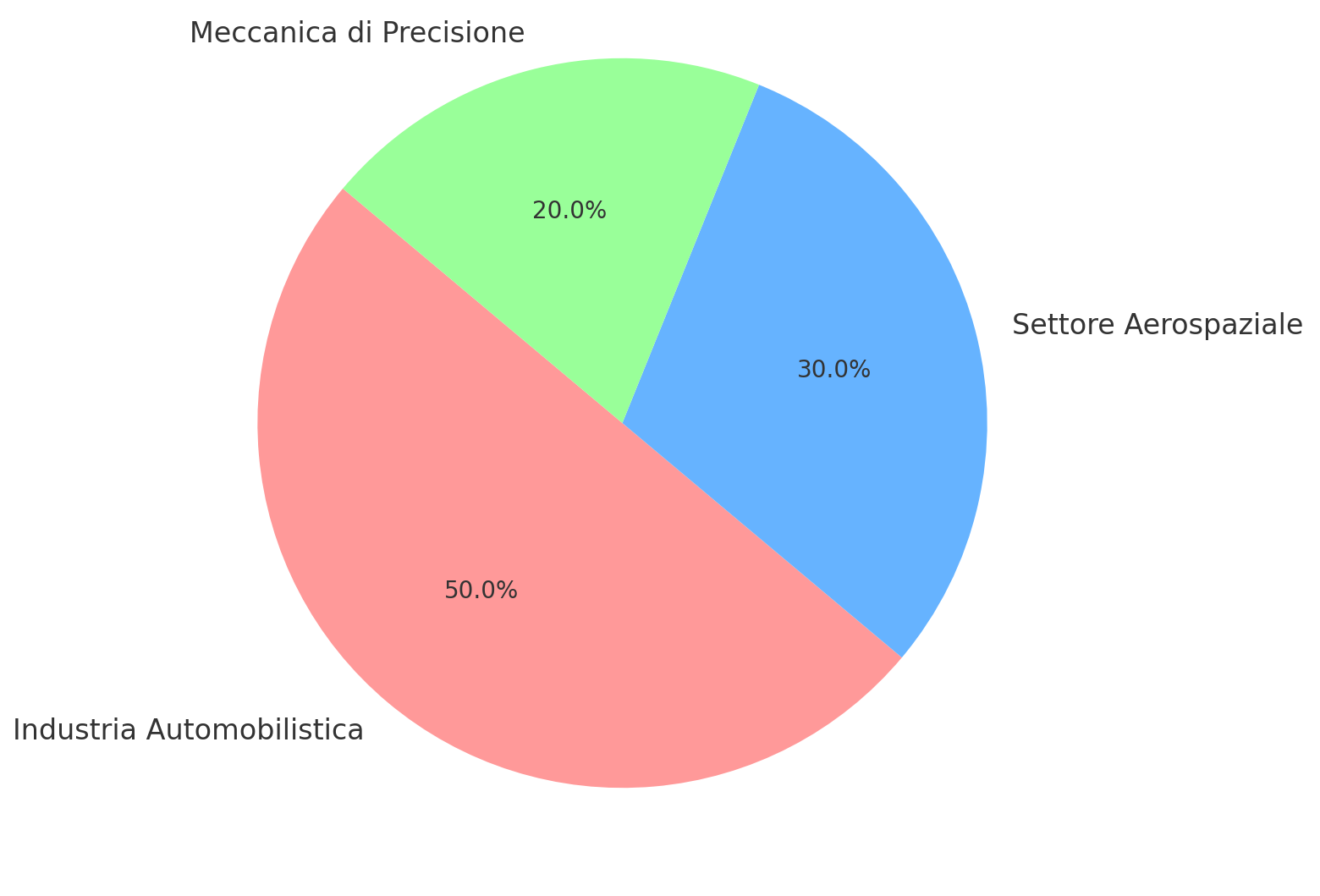

Graph: Milling Applications Distribution

Below is a graph showing the percentage distribution of common milling applications: This graph highlights how milling is widely used in the automotive, aerospace, and precision mechanics industries, where surface quality and precision are essential.

Advantages and Challenges of Milling

Advantages:

- Process Versatility: Milling can machine a wide variety of materials, from ferrous and non-ferrous metals to composites and plastics, allowing for the creation of complex geometries and high-quality surfaces.

- High Dimensional Precision: Milling enables the production of components with tight tolerances and excellent surface finishes, reducing the need for further processing.

- Capability to Machine Complex Shapes: Milling is ideal for creating complex 3D surfaces, grooves, and pockets, offering great flexibility in component design.

Challenges:

- Tool Wear: Wear of milling tools can affect surface quality and increase production costs, requiring careful tool management.

- Chip Removal: Efficient chip removal during milling is essential to avoid machining defects and improve workpiece quality.

- Vibration Control: Vibrations during milling can compromise surface quality and workpiece precision, requiring optimized machining strategies.

Commercial Conclusion

Milling is an extremely versatile and precise chip removal mechanical processing technique, essential for the production of complex, high-quality components. While it presents challenges such as tool wear and chip management, its advantages in terms of precision, versatility, and ability to machine complex shapes make it a primary choice for industries such as automotive, aerospace, and precision mechanics.