ALLOYING ELEMENTS IN STEEL

Steel is an alloy primarily composed of iron and carbon. However, the addition of other alloying elements can significantly enhance its properties, making it suitable for a wide range of applications.

Alloying elements influence the strength, hardness, ductility, corrosion resistance, and other mechanical properties of steel.

Main Alloying Elements and Their Effects

1. Chromium (Cr)

Chromium is one of the most commonly added elements to steel. It provides corrosion and oxidation resistance, while also increasing hardness and wear resistance.

- Stainless steels: Contain at least 10.5% chromium, offering excellent corrosion resistance.

2. Nickel (Ni)

Nickel increases hardness, corrosion resistance, and toughness. It is essential in austenitic stainless steels.

- Austenitic stainless steels: Contain at least 8% nickel, resulting in a non-magnetic structure with high corrosion resistance.

3. Manganese (Mn)

Manganese improves wear resistance and hardness. It also acts as a deoxidizer during steel production.

- Manganese steels: Used in applications requiring high wear resistance, such as railway tracks.

4. Molybdenum (Mo)

Molybdenum increases strength and hardness at high temperatures. It also enhances corrosion resistance in acidic environments.

- Chromium-molybdenum steels: Used in high-temperature applications such as boilers and reactors.

5. Vanadium (V)

Vanadium improves hardness and wear resistance. It strengthens the steel’s microstructure, enhancing fatigue resistance.

- Vanadium steels: Used in cutting tools and high-strength components.

Tables and Images

Main Alloying Elements and Their Effects on Steel

| Element | Effetti principali | Applicazioni |

|---|---|---|

| Chromium (Cr) | Corrosion and oxidation resistance, hardness | Stainless steels, tools |

| Nickel (Ni) | Corrosion resistance, toughness | Austenitic Stainless Steels |

| Manganese (Mn) | Wear resistance, hardness | Railway tracks, agricultural machinery |

| Molybdenum (Mo) | High-temperature resistance, hardness | Boilers, reactors |

| Vanadium (V) | Hardness, wear resistance | Cutting tools, high-strength components |

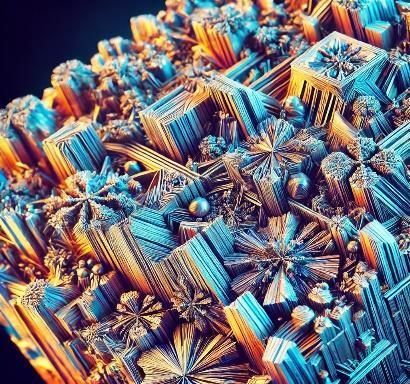

Image 1:

Micrographic Structure of Chromium Steel

Image 2:

Nickel Steel Components