ANNEALING

Annealing is a heat treatment process used to alter the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness, making it more workable. This process is commonly applied to metals and alloys, especially steels, to improve workability and refine the material’s structure.

Principles of Annealing

The annealing process consists of three main stages:

- Heating: The material is heated to a specific temperature above its recrystallization point.

- Holding: The material is maintained at this temperature for a sufficient period to allow recrystallization.

- Cooling: The material is slowly cooled, usually in a furnace, to prevent thermal stress formation.

Types of Annealing

1. Recrystallization Annealing

- Purpose: Eliminates the effects of work hardening, restoring the material’s original crystalline structure.

- Application: Commonly used for cold-worked steels and alloys.

2. Full Annealing

- Purpose: The material is heated above the upper critical temperature, followed by slow cooling.

- Application: Used to achieve a homogeneous structure and improve workability, especially in carbon steels.

3. Softening Annealing

- Purpose: Reduces the hardness of cold-worked materials, making further machining operations easier.

- Application: Mainly applied to carbon and alloy steels.

Effects of Annealing

Hardness Reduction

Annealing decreases material hardness, improving its workability and making it more suitable for subsequent machining processes.

Increased Ductility

The process enhances the material’s ductility, allowing greater plastic deformation without fracture.

Microstructure Improvement

Annealing helps achieve a refined and homogeneous microstructure, eliminating defects and inconsistencies.

Tables and Graphs

Table 1: Types of Annealing and Their Applications

| Annealing Type | Temperature (°C) | Holding Time | Materiali Tipici | Effetti Principali |

|---|---|---|---|---|

| Recrystallization Annealing | 550-700 | 1-2 hours | Cold-worked steels | Eliminates work hardening |

| Full Annealing | 800-950 | 2-6 hours | Carbon steels | Improves workability |

| Softening Annealing | 650-750 | 1-4 hours | Alloy steels | Reduces hardness |

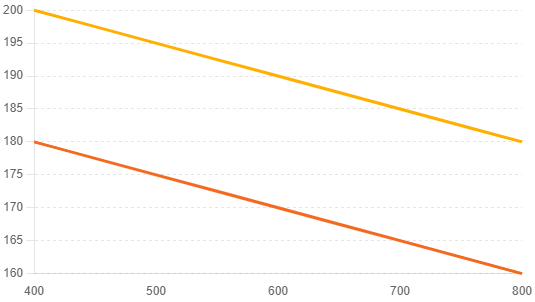

Graph 1: Effect of Annealing on Hardness

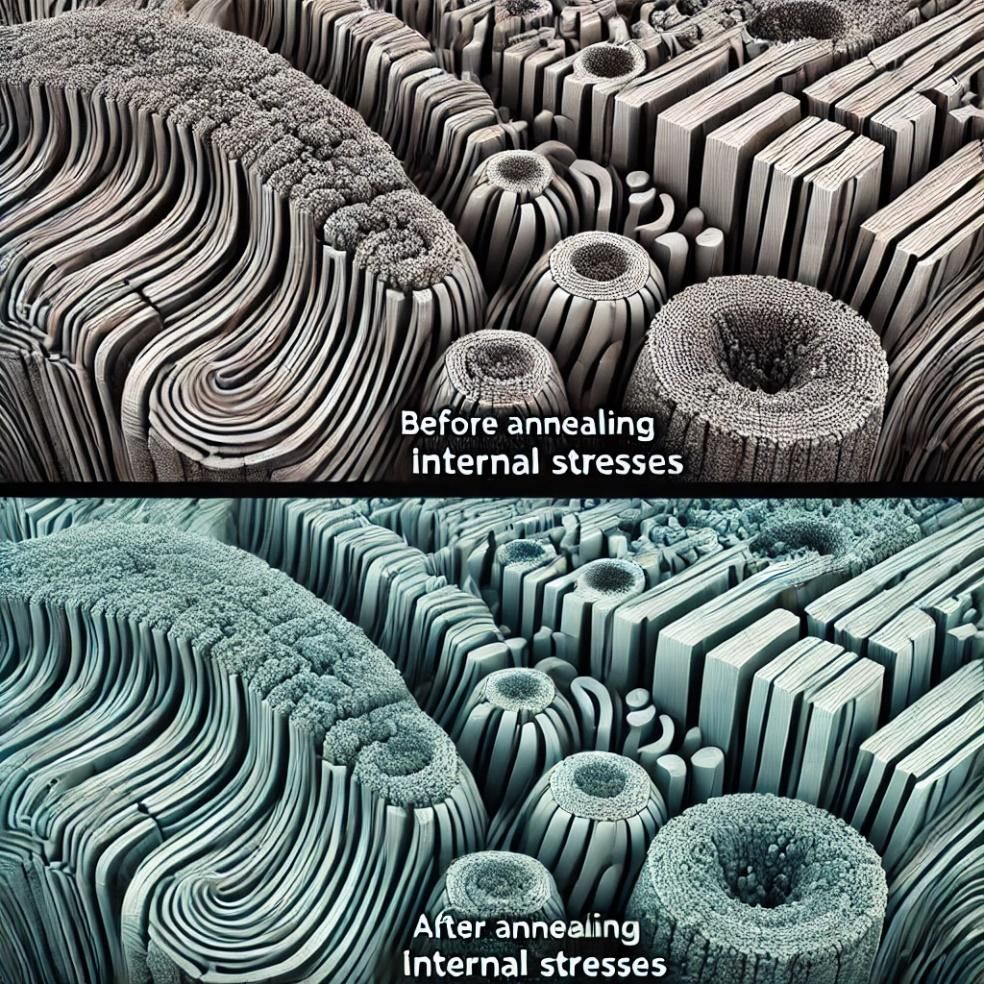

Image 1: Microstructure Before and After Annealing

Conclusion

Annealing is a crucial process for industries working with metals and alloys, particularly steels. This heat treatment not only enhances material workability but also optimizes mechanical properties, ensuring high-quality and high-performance final products.

Investing in modern annealing facilities and optimizing thermal processes allows companies to increase productivity and reduce operational costs. The ability to provide high-quality annealed materials with homogeneous microstructures and optimal mechanical properties represents a significant competitive advantage in the global market.

The adoption of advanced annealing technologies, supported by rigorous quality control, enables the production of materials that meet customer specifications and exceed expectations. This approach not only enhances customer satisfaction but also strengthens the company's reputation as a reliable and innovative supplier.