CLASSIFICATION OF CARBON STEELS

Carbon steels are one of the most widely used metallic alloys in the mechanical and metallurgical industries. They are primarily composed of iron and carbon, with the carbon content playing a crucial role in determining the material's mechanical properties. The classification of carbon steels is mainly based on their carbon content, which directly influences hardness, strength, and ductility.

Classification of Carbon Steels

Carbon steels can be classified into three main categories:

- Low-carbon steels (up to 0.3% C)

- Medium-carbon steels (0.3% - 0.6% C)

- High-carbon steels (above 0.6% C)

Properties of Carbon Steels

| Steel Type | Carbon Content | Hardness (HV) | Tensile Strength (MPa) | Ductility |

|---|---|---|---|---|

| Low-carbon steel | Up to 0.3% | 100-180 | 400-550 | High |

| Medium-carbon steel | 0.3% - 0.6% | 180-300 | 550-800 | Moderate |

| High-carbon steel | Above 0.6% | 300-600 | 800-1200 | Low |

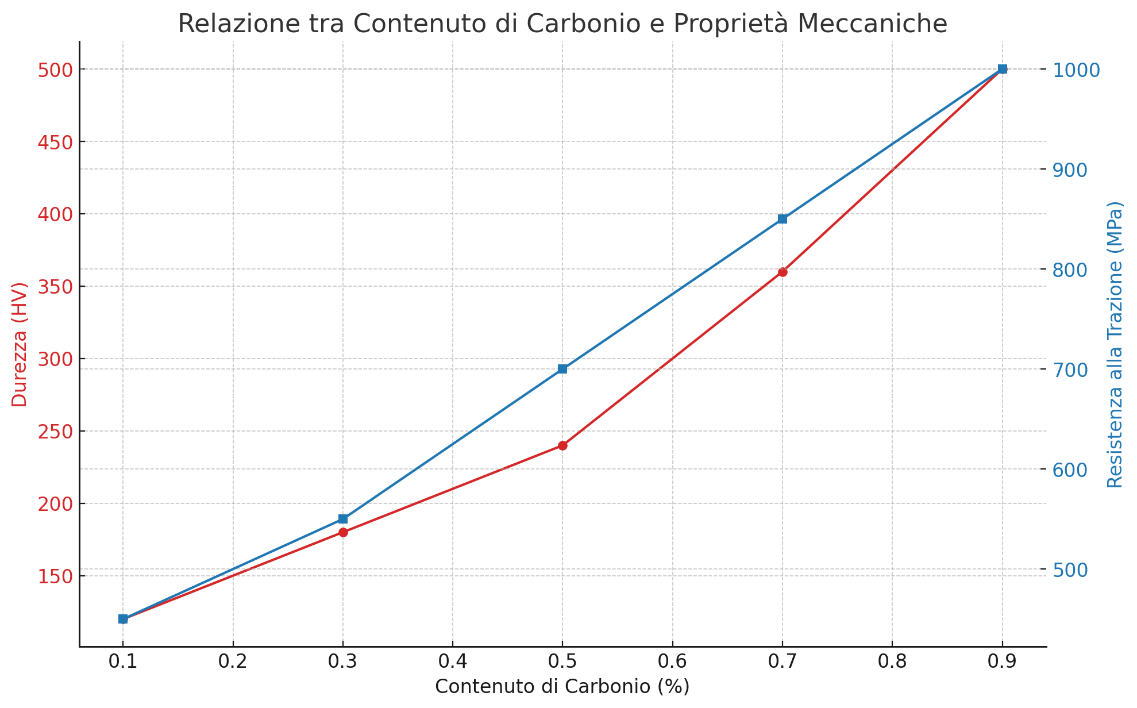

Graph: Relationship Between Carbon Content and Mechanical Properties

The graph above illustrates how carbon content influences the hardness and tensile strength of carbon steels.

Microstructure Images

The following image shows the typical microstructure of carbon steels with varying carbon percentages.

Heat Treatments

Heat treatments such as quenching, annealing, and tempering are commonly used to modify the properties of carbon steels. These thermal processes can increase hardness, improve tensile strength, or enhance ductility depending on the application requirements.

| Heat Treatment | Main Effects |

|---|---|

| Quenching | Increases hardness and strength |

| Annealing | Reduces internal stresses, increases ductility |

| Tempering | Adjusts hardness and strength |

Conclusion

Carbon steels are a versatile and cost-effective choice for many industrial applications. Their wide range of mechanical properties makes them suitable for structural components, tools, machinery parts, and more. Investing in high-quality carbon steels ensures durability, efficiency, and reliability in manufacturing processes.

For companies looking to optimize their operations, selecting the right type of carbon steel, combined with appropriate heat treatments, can lead to significant improvements in product performance. Partnering with experienced and reliable suppliers is essential to ensure materials that meet stringent quality standards.