CAST IRON

Cast iron is a ferrous alloy containing a high percentage of carbon, usually above 2%, along with silicon and other trace elements. It is known for its excellent castability, good wear resistance, and relatively low cost, making it suitable for many industrial and structural applications.

Classification of Cast Iron

Cast iron can be classified into several main categories, each with specific properties that make it suitable for different applications:

- Gray Cast Iron

- Ductile Cast Iron

- White Cast Iron

- Malleable Cast Iron

Properties of Cast Iron

| Type of Cast Iron | Carbon Content (%) | Main Characteristics | Typical Applications |

|---|---|---|---|

| Gray Cast Iron | 2.5 - 4.0 | Good castability, vibration damping | Engines, machine frames |

| Ductile Cast Iron | 3.0 - 4.0 | High ductility, good mechanical strength | Pipes, gears, shafts |

| White Cast Iron | 1.8 - 3.6 | High hardness, brittle | Wear-resistant parts |

| Malleable Cast Iron | 2.0 - 3.0 | Good ductility, easy machinability | Joints, fittings, small components |

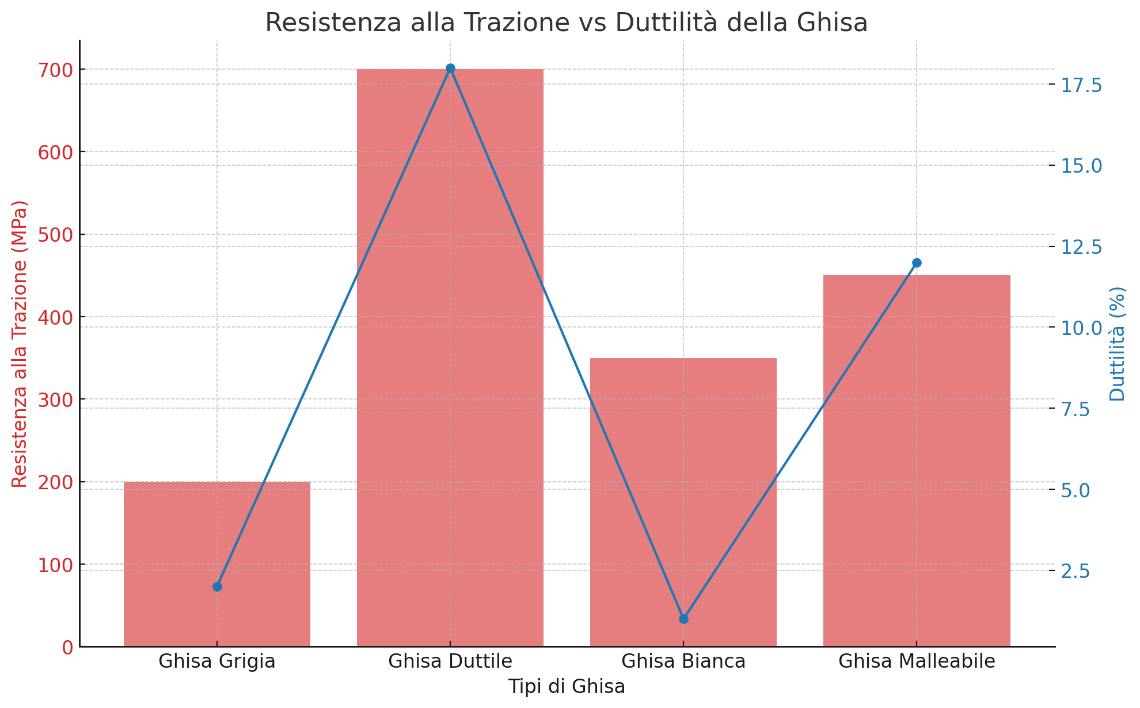

Graph: Tensile Strength vs Ductility of Cast Iron

The graph above shows the relationship between tensile strength and ductility for different types of cast iron.

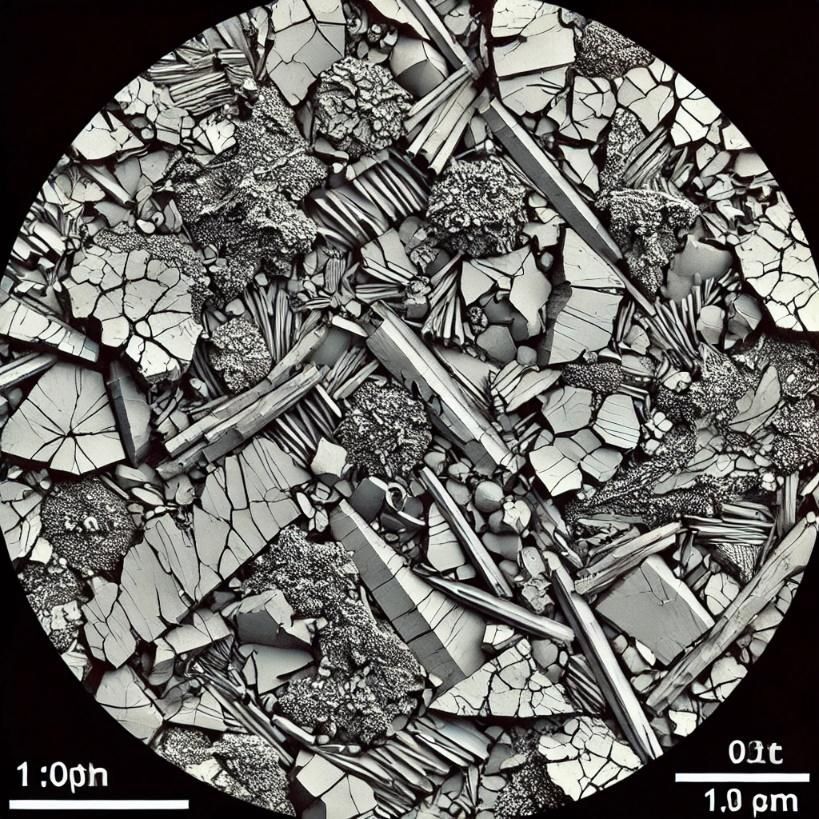

Microstructure Images

The following image shows the typical microstructure of gray cast iron:

Applications of Cast Iron

Cast iron is used in various industries, including:

- Mechanical Engineering: Used for machine components, engines, and frames.

- Infrastructure: Used for pipes, grates, and support structures.

- Automotive Industry: Used for engine blocks, cylinders, and brake discs.

- Urban Furnishings: Used for benches, lampposts, and other decorative structures.

Conclusion

Cast iron is an advantageous choice for companies looking for materials with excellent castability, wear resistance, and cost efficiency. Its versatility makes it ideal for a wide range of industrial and structural applications. Investing in high-quality cast iron can lead to significant economic benefits, reducing production costs and improving product durability.

For companies seeking to enhance the reliability and efficiency of their manufacturing processes, choosing the right type of cast iron, combined with proper knowledge of heat treatments and machining techniques, is crucial to ensuring high quality and performance standards.