Main sectors

FM Metal Fasteners Group S.p.A.

Main sectors

Our fasteners are used in numerous industrial sectors, from automotive to mechanical engineering, from agriculture to construction.

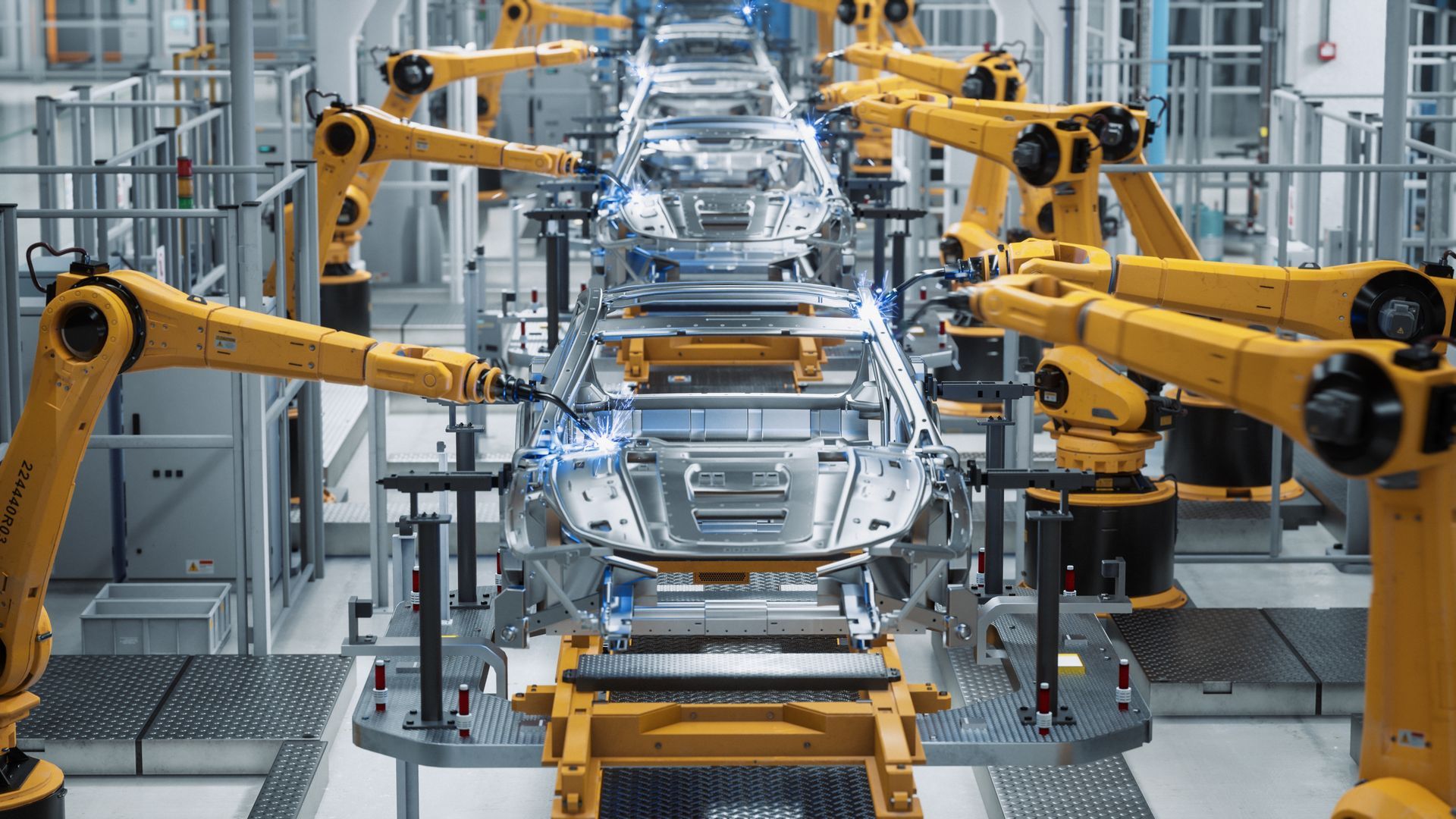

Automotive

Fasteners are essential for assembling vehicles and components, ensuring strength and safety

They are made from high-strength materials to withstand stress, vibration, and extreme environmental conditions, complying with rigorous quality standards (ISO). Advanced fastening solutions improve assembly efficiency and reduce production times. Choosing these fasteners means investing in quality, precision, and a partner for success in the automotive market.

Building and construction

Fasteners are essential for the strength, safety and durability of structures

In the construction industry, they securely join structural components to withstand heavy loads, climate change, and earthquakes. High-strength materials (stainless steel, galvanized alloys) are used to prevent corrosion. They must meet stringent standards (ISO). Advanced fastening technologies improve efficiency and reduce construction times. They are an ideal choice for innovative and reliable solutions, improving the safety, efficiency, and durability of buildings.

Railway industry

Fasteners must withstand extreme load, vibration and environmental conditions

In this sector, they are vital to the safety, reliability, and longevity of railway infrastructure. Advanced materials (high-strength steel, corrosion-resistant alloys) are used to prevent wear. They must meet rigorous quality and safety standards. Advanced fastening technologies improve assembly and reduce maintenance. They are the ideal choice for companies seeking reliable solutions that improve safety, reliability, and performance.

Energy industry

Fasteners must hold critical parts securely in place and withstand extreme environmental conditions.

In the industry, they are essential for the stability and efficiency of energy infrastructure (power plants, wind turbines). High-strength steels and corrosion-resistant alloys are used for durability and reliability. They must meet rigorous quality and safety standards and are tested for mechanical, thermal, and chemical resistance. Advanced technologies improve installation and operational safety, offering an ideal choice for innovative and reliable solutions.

Home appliances

Fasteners are essential to the quality, durability and safety of household appliances.

In household appliances, they firmly connect internal and external components. They are made of high-quality materials (galvanized steel, special alloys) to resist wear, vibration, and thermal stress. They must meet specific safety standards (IEC, UL). Technologies such as anti-rust coatings and precise tightening ensure long life. They are the ideal choice for manufacturers seeking reliable and innovative solutions, optimizing performance and longevity.

Agricultural industry

Fasteners are crucial to the strength and efficiency of agricultural equipment

In agriculture, equipment faces extreme conditions (dust, mud, humidity). Resistant materials (galvanized steel, aluminum alloys) offer durability and lightness. Fasteners must meet rigorous strength and reliability standards (ISO). Advanced technologies such as anti-corrosion coatings and controlled tightening improve resistance and reduce maintenance. They are an ideal choice for reliable and customized solutions, improving the efficiency and longevity of equipment.

Renewable energy sector

Fasteners must ensure secure and long-lasting connections, in extreme environmental conditions

(temperature, UV, wind)

They are essential for building and maintaining long-lasting and efficient infrastructure in this sector. Materials such as stainless steel and titanium are used for corrosion and fatigue resistance. Emphasizing the high quality of fasteners promotes robustness and reliability. Innovation (special coatings, anti-vibration locking systems) reduces operating costs. Sustainability (recycled materials) is crucial for marketing. Smart fasteners with sensors offer added value for predictive maintenance.

Communications industry

Fasteners must ensure strong and long-lasting connections, resisting vibration, climate and corrosion

They are crucial to the functionality and security of telecommunications infrastructure (towers, data centers, network devices). High-strength materials and special treatments are used for a long service life. The use of high-quality fasteners strengthens reputation and competitiveness. Innovation (automatic locking, lightweight composite materials) increases efficiency and reduces maintenance. Sustainability (eco-friendly materials) and security (preventing unauthorized access) are important marketing considerations.

Arrange a meeting or call

Need more information? Our team is at your complete disposal to provide you with further information, answer any questions you may have, and configure the system that best suits your needs.

Fill out the form and choose how you'd like to meet with us: a phone consultation, a meeting at your office, a meeting at our office for a demo, or simply request a call.

We will show you the solutions and useful steps, without obligation.

Don't want to fill out the contact form?

Call us or send us an e-mail!

39 0522 271117

commerciale@fmspa.com