NORMALIZATION

Normalization is a heat treatment applied to steels to improve their crystalline structure and optimize mechanical properties. This process consists of heating the steel to a temperature above the critical point, followed by controlled air cooling. Normalization is essential to achieve a uniform microstructure distribution, reduce internal stresses, and enhance the ductility and strength of the steel.

Normalization Processes

Stages of Normalization

- Heating: The steel is heated to a temperature between 800°C and 950°C, depending on the type of steel.

- Holding: The material is maintained at the desired temperature for a sufficient period to ensure homogeneous crystalline structure formation.

- Cooling: The steel is air-cooled, allowing for a controlled transformation of the microstructure.

Effects of Normalization

Microstructure Improvement

Normalization reduces grain size and evenly distributes carbides in the steel, improving mechanical properties such as strength and ductility.

Reduction of Residual Stresses

The controlled heating and cooling process relieves internal stresses accumulated during hot working or welding, reducing the risk of deformation and fractures.

Applications of Normalization

Mechanical Sector

- Gears: Normalization enhances wear resistance and increases gear longevity.

- Drive Shafts: It reduces residual stresses, improving fatigue resistance.

Construction Sector

- Steel Structures: Improves strength and stability of load-bearing structures.

- Welded Components: Reduces the risk of cracks and post-welding deformations.

Tables and Charts

Table 1: Mechanical Properties of Normalized Steels

| Type of Steel | Tensile Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|

| Carbon Steel | 400-600 | 25-25 | 120-180 |

| Manganese Steel | 600-800 | 15-20 | 180-240 |

| Chromium-Molybdenum Steel | 800-1000 | 10-15 | 200-260 |

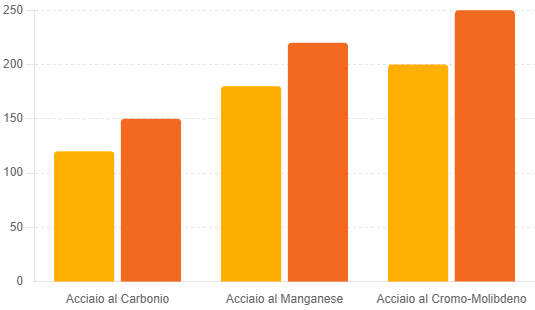

Chart 1: Effect of Normalization on Steel Hardness

Images

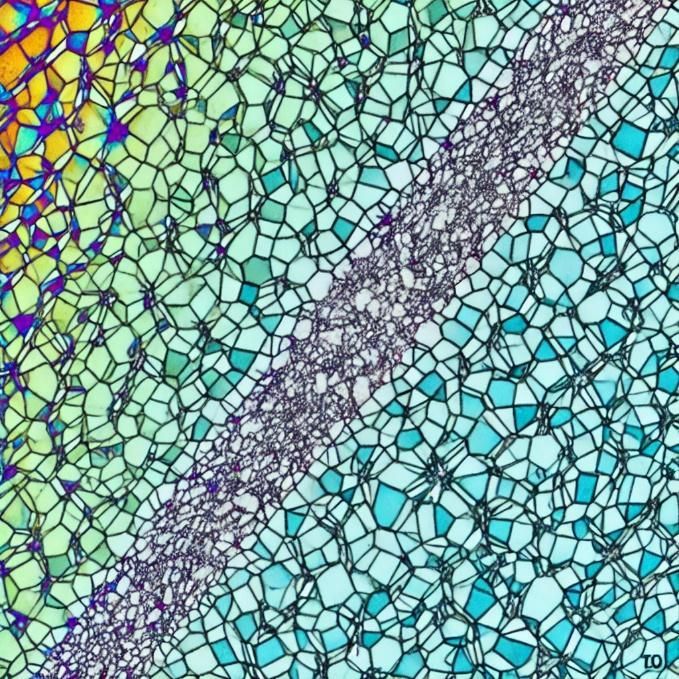

Image 1: Crystalline Structure of Normalized Steel

Conclusion

Normalization is an essential process for optimizing the mechanical properties of steels, enhancing their strength, ductility, and dimensional stability. Companies investing in this heat treatment can ensure high-quality products while minimizing risks of deformation and cracks due to internal stresses.