STAINLESS STEELS

Stainless steels are a family of metal alloys characterized by their resistance to corrosion. This unique property is mainly due to the presence of chromium, which forms a passive layer of chromium oxide on the material’s surface. Stainless steels are widely used in applications requiring durability, hygiene, and corrosion resistance.

Classification of Stainless Steels

Stainless steels can be classified into several main categories, each with specific properties that make them suitable for various applications:

- Austenitic Stainless Steels

- Ferritic Stainless Steels

- Martensitic Stainless Steels

- Duplex Stainless Steels

- Precipitation-Hardening Stainless Steels

Properties of Stainless Steels

| Steel Type | Main Composition | Corrosion Resistance | Mechanical Strength | Ductility |

|---|---|---|---|---|

| Austenitic | Cr 16-26%, Ni 6-22% | Excellent | Good | High |

| Ferritic | Cr 10.5-27% | Good | Moderate | Moderate |

| Martensitic | Cr 11-17%, C 0.1-1.2% | Moderate | High | Low |

| Duplex | Cr 18-28%, Ni 4.5-8% | Excellent | Very High | Moderate |

| Precipitation-Hardening | Cr 12-18%, Ni 3-9% | Excellent | Very High | Low |

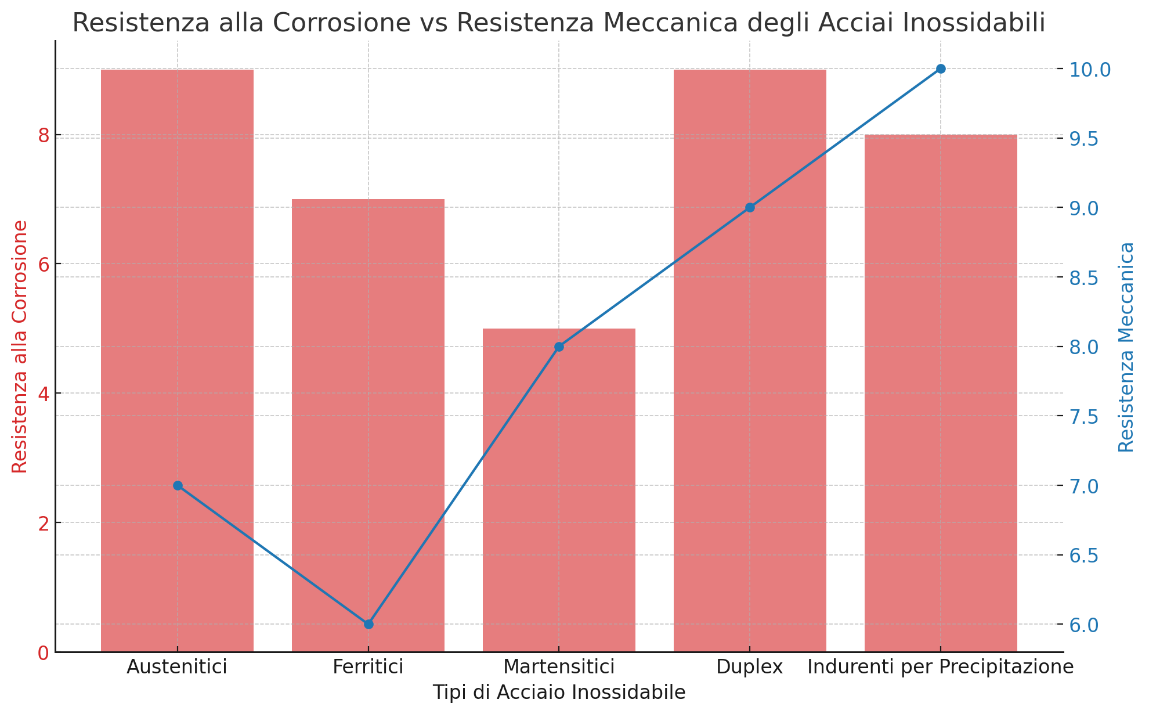

Graph: Corrosion Resistance vs Mechanical Strength

The graph illustrates the relationship between corrosion resistance and mechanical strength for different types of stainless steels.

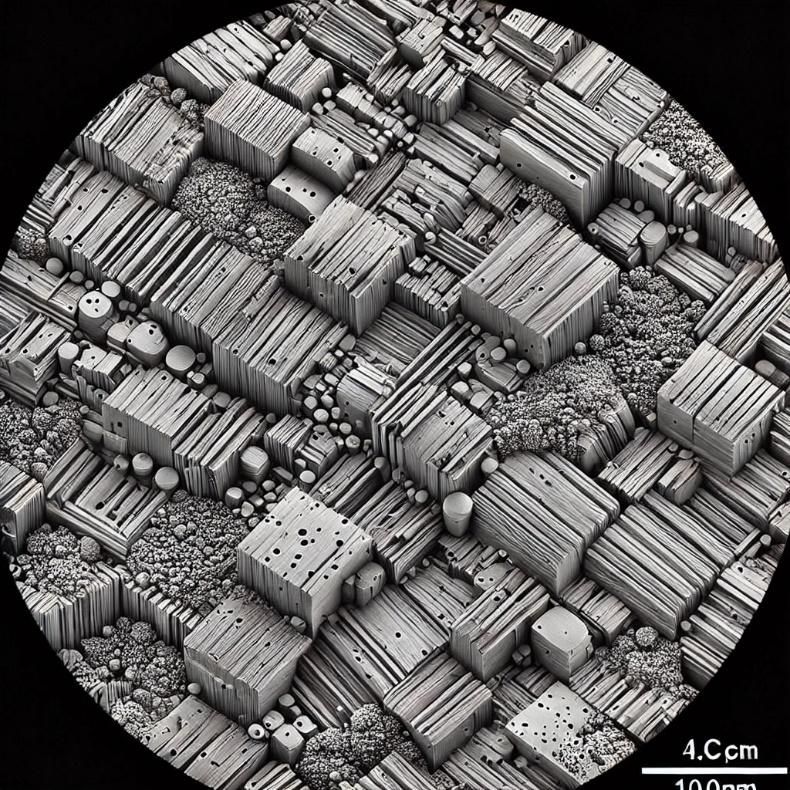

Microstructure Images

The following image shows the typical microstructure of an austenitic stainless steel.

Applications of Stainless Steels

Stainless steels are widely used in various industries, including:

- Food Industry: Used for kitchen tools, food containers, and processing equipment.

- Medical Sector: Used for surgical instruments, implants, and medical devices.

- Construction: Used for architectural elements, structures, and cladding.

- Automotive Industry: Used for exhaust components, engine parts, and body panels.

- Chemical Industry: Used for reactors, pipelines, and storage tanks.

Conclusion

Stainless steels are an excellent choice for companies looking for durable, corrosion-resistant materials with a good strength-to-weight ratio. Their versatility makes them ideal for a wide range of industrial and commercial applications. Investing in high-quality stainless steels can lead to significant long-term economic benefits by reducing maintenance costs and increasing product lifespan.

For companies aiming to improve the reliability and efficiency of their manufacturing processes, collaborating with experienced and reliable suppliers is essential to ensure access to materials that meet stringent quality and performance standards.