SURFACE HARDENING

Surface hardening is a heat treatment used to harden the surface of metal components, improving their wear resistance, fatigue strength, and deformation resistance. This process involves the rapid heating of the material's surface, followed by equally rapid cooling, while the core remains relatively untreated, maintaining its toughness.

Surface Hardening Techniques

1. Induction Hardening

Induction hardening uses an electromagnetic field to rapidly heat the surface of the material. This method is highly controllable and can be applied to specific areas of a component.

2. Flame Hardening

Flame hardening uses a gas burner to heat the surface of the component. This method is suitable for large parts or complex shapes that require localized heating.

3. Laser Hardening

Laser hardening utilizes a high-power laser beam to heat the surface of the material. This method offers extremely precise heating control and is ideal for very small or complex components.

4. Plasma Hardening

Plasma hardening uses an electric arc to generate plasma that heats the material’s surface. It is an efficient method for treating components with complex geometries.

Advantages of Surface Hardening

- Increased Surface Hardness: Enhances wear and fatigue resistance.

- Core Toughness Retention: The material’s core remains tough, preventing fractures.

- Localized Treatment: Only necessary areas are hardened, reducing distortion.

- Application Flexibility: Suitable for various materials and component shapes.

Tables and Charts

Table: Surface Hardening Techniques and Their Characteristics

| Technique | Suitable Materials | Advantages | Applications |

|---|---|---|---|

| Induction Hardening | Steels, cast irons | Fast and controlled heating | Gears, shafts, bearings |

| Flame Hardening | Steels, cast irons, alloys | Suitable for large parts | Axles, rollers, railway components |

| Laser Hardening | Steels, light alloys | High precision, minimal distortion | Cutting tools, gears |

| Plasma Hardening | Steels, cast irons, alloys | Efficient, ideal for complex shapes | Aerospace components, turbines |

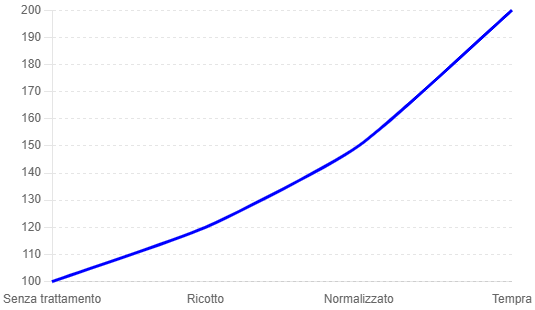

Chart: Increase in Surface Hardness

Images

Image 1: Induction Hardening Process

Applications of Surface Hardening

- Gears: Improved wear and fatigue resistance for longer durability.

- Shafts: Increased surface hardness for better stress resistance.

- Bearings: Surface hardening for enhanced wear resistance.

- Cutting Tools: Increased hardness for extended tool life.

Conclusion

Surface hardening is an advanced solution to enhance the durability and performance of metal components. Companies investing in these technologies can offer products with higher wear and fatigue resistance, reducing maintenance costs and increasing customer satisfaction.

By using surface hardening, specific areas of components can be treated without compromising core toughness, providing an optimal combination of surface hardness and internal strength. This makes surface-hardened components ideal for critical applications in industries such as automotive, aerospace, and tool manufacturing.