TITANIUM

Titanium is a lightweight and strong metal, known for its excellent corrosion resistance and extremely favorable strength-to-weight ratio. Thanks to these properties, titanium is widely used in industries such as aerospace, medical, and chemical.

Properties of Titanium

Mechanical and Physical Properties

| Property | Typical Value |

|---|---|

| Density | 4.51 g/cm³ |

| Melting Point | 1668 °C |

| Tensile Strength | 434 MPa (pure Ti) |

| Elastic Modulus | 116 GPa |

| Thermal Conductivity | 21.9 W/m·K |

| Elongation | 30% |

Chemical Composition

Commercially pure titanium contains at least 99% titanium, with small amounts of oxygen, nitrogen, carbon, and iron as impurities. Titanium alloys may include elements such as aluminum, vanadium, and molybdenum to further enhance mechanical properties and corrosion resistance.

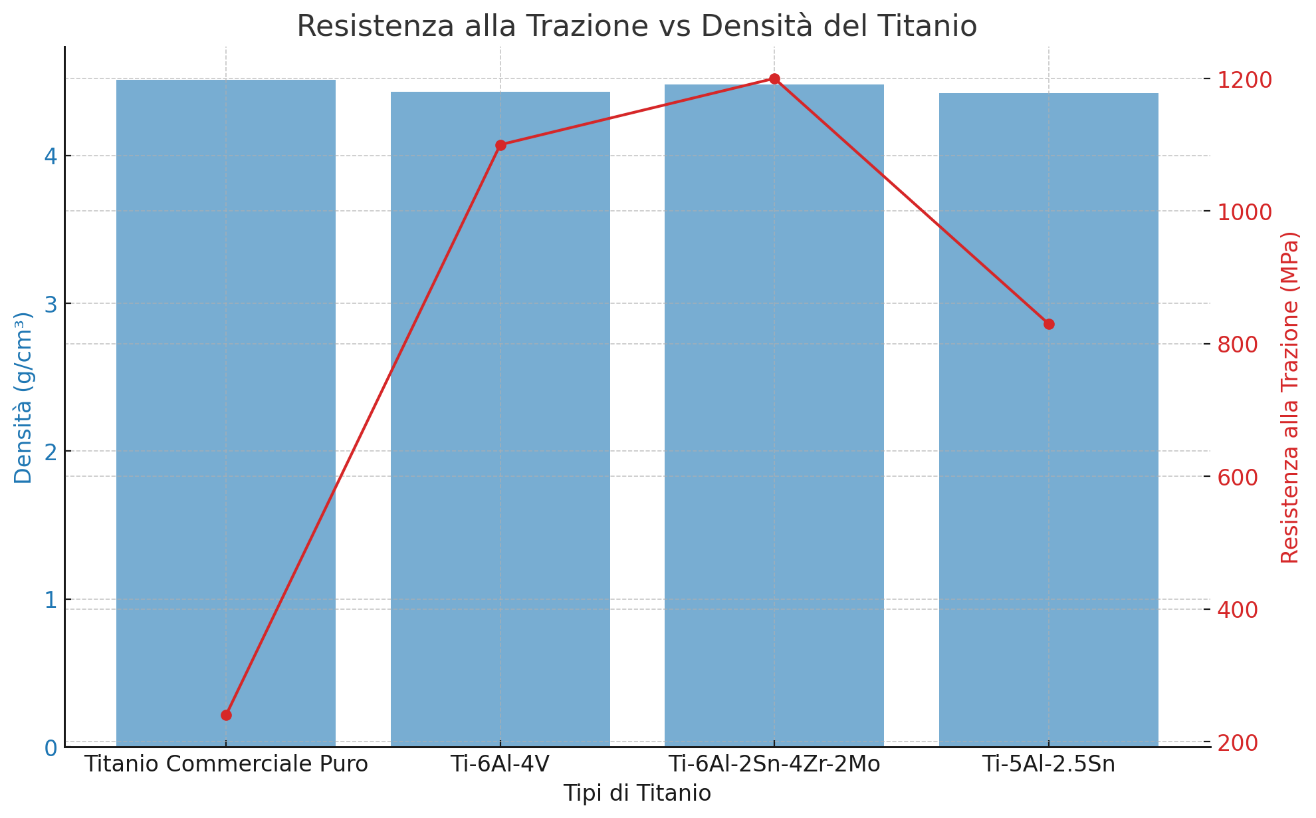

Graph: Tensile Strength vs Density

The graph shows the relationship between tensile strength and density of titanium compared to other lightweight metals, such as aluminum and magnesium.

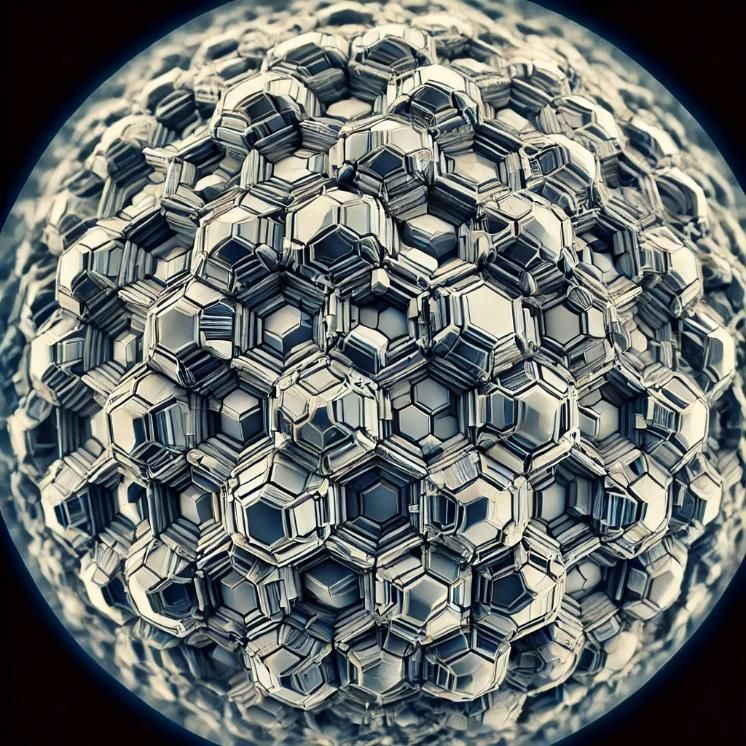

Microstructure Images

The following image shows the typical microstructure of pure titanium:

Classification of Titanium

Titanium and its alloys are classified into four main grades based on purity and alloying elements:

- Commercially Pure Titanium (Grades 1-4)

- Titanium-Aluminum-Vanadium Alloys (Grade 5)

- Titanium-Palladium Alloys (Grade 7)

- Titanium-Zirconium Alloys (Grade 9)

Properties of Different Titanium Grades

| Grade | Composition | Tensile Strength (MPa) | Ductility | Typical Applications |

|---|---|---|---|---|

| 1 | Pure Ti | 240-370 | High | Chemical, medical |

| 5 | Ti-6Al-4V | 895-930 | Moderate | Aerospace, biomedical |

| 7 | Ti-0.2Pd | 240-370 | High | Chemical, marine |

| 9 | Ti-3Al-2.5V | 620-690 | High | Sports, automotive |

Applications of Titanium

Titanium is used in various industries, including:

- Aerospace: Used for aircraft structural components, engines, and landing gear due to its high specific strength and corrosion resistance.

- Medical: Used for orthopedic implants, surgical instruments, and medical devices due to its biocompatibility.

- Chemical Industry: Used for heat exchangers, tanks, and piping in corrosive environments.

- Sports Industry: Used for bicycles, sports equipment, and high-performance vehicles due to its lightness and strength.

Titanium Treatments and Processing

Titanium can undergo various treatments and processing methods to enhance its properties and adapt it to specific applications. These include:

- Heat Treatments: Used to improve mechanical strength and toughness.

- Cold Working: Used to increase strength and reduce ductility.

- Protective Coatings: Applied to further enhance corrosion resistance in extreme environments.

Conclusion

Titanium is an excellent choice for companies seeking lightweight, strong, and highly corrosion-resistant materials. Its versatility makes it ideal for a wide range of industrial and commercial applications. Investing in high-quality titanium can bring significant economic advantages, improving product durability and reducing maintenance costs. Choosing experienced and reliable suppliers is crucial to ensuring the procurement of materials that meet stringent quality and performance standards.