MACHINING BY CHIP REMOVAL: TURNING

Introduction

Turning is one of the most widely used machining processes for chip removal, employed to create cylindrical, conical, or profiled surfaces on a workpiece. During the turning process, a sharp cutting tool removes material from the rotating workpiece, generating chips. This method is extensively used in various industrial sectors, including automotive, aerospace, energy, and precision mechanics, due to its ability to produce components with high dimensional accuracy and surface finish.

Turning Process

The turning process can be divided into several stages, each playing a crucial role in ensuring the quality and specifications of the final component. Below is a description of the main phases of turning:

1. Workpiece Preparation

- Description: The workpiece is secured in the chuck of the lathe. It is essential that the workpiece is properly centered and clamped to prevent vibrations during machining.

- Applications: This phase is critical for achieving optimal dimensional accuracy and surface finish.

2. Tool Selection and Preparation

- Description: The cutting tool is selected based on the material of the workpiece and the type of machining required (roughing, finishing, profiling). Tool preparation includes sharpening and mounting on the lathe turret.

- Applications: Proper selection and preparation of the tool directly affect surface quality and tool lifespan.

3. Machining

- Description: During turning, the workpiece rotates while the tool moves along the longitudinal or transverse axis of the piece, removing material in the form of chips. Machining parameters, such as cutting speed, feed rate, and depth of cut, are adjusted based on the specifications of the piece.

- Applications: This phase enables achieving the desired dimensions and the final shape of the component, which can be cylindrical, conical, or profiled.

4. Quality Control and Finishing

- Description: Once machining is complete, the piece undergoes dimensional and surface inspections to ensure compliance with required tolerances. Additional finishing operations, such as grinding or polishing, may be performed to further improve surface quality.

- Applications: Ensures that the final component meets technical specifications and customer requirements.

Turning Parameters Table

| Turning Parameter | Description | Impact on Machining |

|---|---|---|

| Cutting Speed (Vc) | Speed at which the tool contacts the workpiece | Affects tool lifespan and surface quality |

| Feed Rate (f) | Tool movement speed per revolution of the workpiece | Determines surface roughness and material removal rate |

| Depth of Cut (ap) | Thickness of material removed per pass | Influences productivity and tool resistance |

| Rake Angle | Angle between the tool and the workpiece during cutting | Affects chip formation and surface quality |

Applications of Turning

Turning is widely used to manufacture a broad range of components in various industrial sectors. Some examples of applications include:

1. Automotive Industry

- Example: Production of crankshafts, brake drums, and wheel hubs. These components require high dimensional precision and mechanical strength.

- Advantages: Turning provides high repeatability and precision, essential for mass production of critical vehicle safety components.

2. Aerospace Sector

- Example: Manufacturing of turbine engine parts and structural components in lightweight alloys. These components must withstand extreme temperature and pressure conditions.

- Advantages: Enables the production of smooth surfaces and tight tolerances, crucial for efficiency and safety in aerospace applications.

3. Precision Mechanics

- Example: Production of components for watches, measuring instruments, and medical devices, where extremely tight tolerances and high-quality surface finishes are required.

- Advantages: Turning allows machining of very small pieces with high precision, meeting the stringent requirements of these industries.

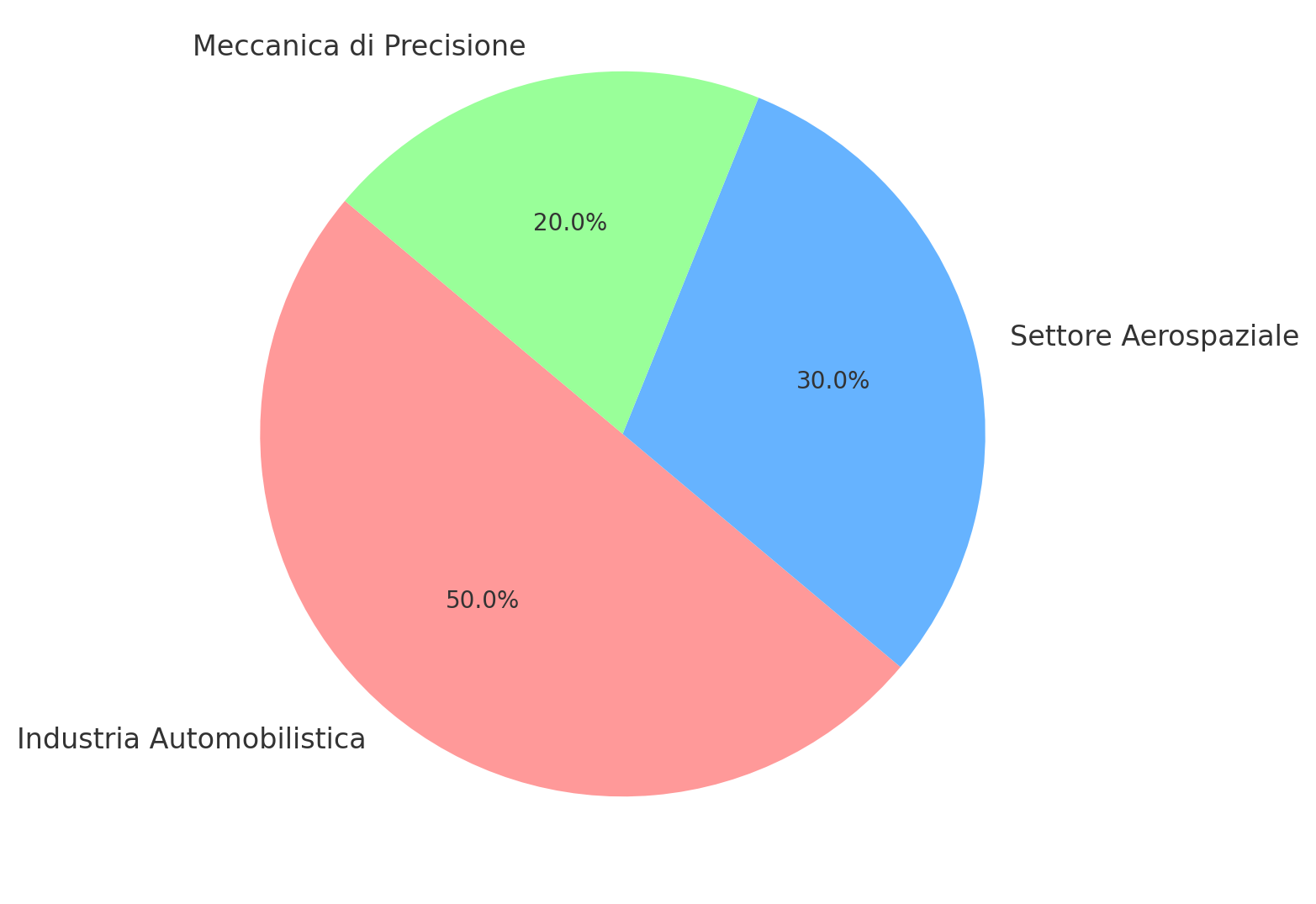

Graph: Distribution of Turning Applications

A graph below illustrates the percentage distribution of common turning applications: This graph highlights how turning is widely used in the automotive, aerospace, and precision mechanics industries, where dimensional precision and surface quality are essential.

Advantages and Challenges of Turning

Advantages:

- High Dimensional Accuracy: Turning allows the production of components with very tight tolerances, reducing the need for additional machining operations.

- Process Versatility: Suitable for a wide range of materials, from ferrous and non-ferrous metals to special alloys and plastics.

- Production Efficiency: Ideal for mass production of cylindrical or profiled components, offering high repeatability.

Challenges:

- Chip Management: The formation of chips during turning can be a challenge, requiring efficient chip evacuation and management systems.

- Tool Wear: Wear of cutting tools is a common issue, which can affect workpiece quality and increase production costs.

- Vibration Control: Vibrations during machining can compromise surface quality and the dimensional accuracy of the workpiece.

Commercial Conclusion

Turning is one of the most reliable and versatile machining techniques for producing cylindrical and profiled components. Despite challenges related to chip management and tool wear, the advantages in terms of precision, repeatability, and versatility make turning a preferred choice for manufacturing critical components in sectors such as automotive, aerospace, and precision mechanics.