UNIFIED THREADS

Introduction

Unified threads are standardized to ensure interchangeability between mechanical components produced in different regions of the world. They are primarily used in the mechanical and manufacturing industries, where precision and reliability are crucial.

Classification of Unified Threads

Unified threads are mainly classified based on two parameters: nominal diameter and thread pitch. The most common classifications are:

- UNC (Unified National Coarse): Used for coarse threads.

- UNF (Unified National Fine): Used for fine threads.

- UNEF (Unified National Extra Fine): Used for extra fine threads.

Table 1: Unified Thread Classifications and Applications

| Thread Type | Nominal Diameter (inches) | Pitch (threads per inch) | Typical Application |

|---|---|---|---|

| UNC | 1/4 - 20 | 20 | Bolting and structural connections |

| UNF | 1/4 - 28 | 28 | Automotive and aerospace components |

| UNEF | 1/4 - 32 | 32 | Precision instruments |

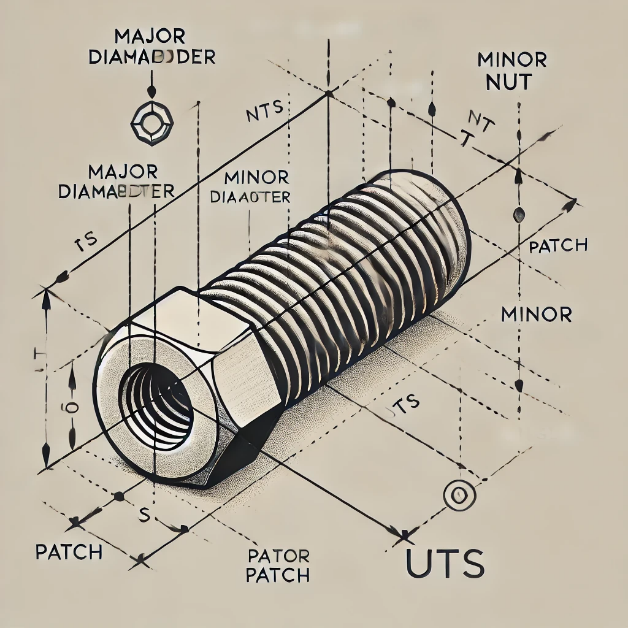

Technical Characteristics

Unified threads are defined by standardized geometric profiles that ensure proper connection between screws and nuts. The main geometric parameters are:

- External diameter (d): Maximum diameter of the thread.

- Internal diameter (d1): Minimum diameter of the thread.

- Thread angle (α): Angle formed by the thread flanks, typically 60°.

Figure 1: Unified Thread Geometry

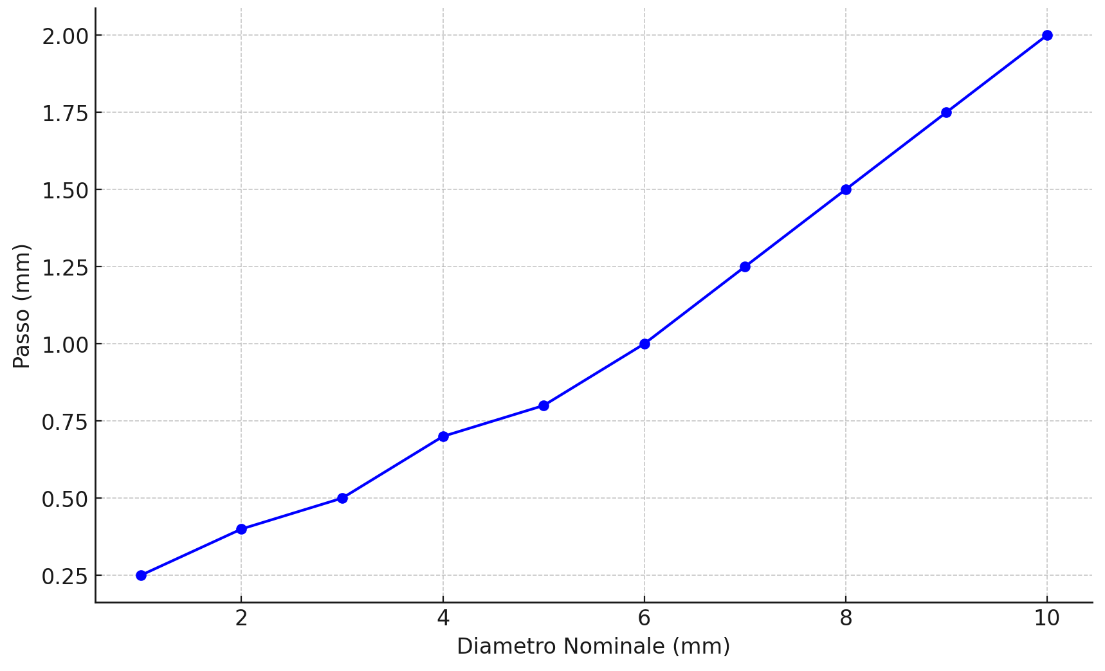

Graph 1: Relationship Between Nominal Diameter and Pitch

Table 2: Main Dimensions of Unified Threads

| Thread Type | Nominal Diameter (inches) | Pitch (threads per inch) | Typical Application |

|---|---|---|---|

| UNC | 1/4 - 20 | 20 | Bolting and structural connections |

| UNF | 1/4 - 28 | 28 | Automotive and aerospace components |

| UNEF | 1/4 - 32 | 32 | Precision instruments |

Production Processes

Unified threads can be manufactured using various production processes, including:

- Turning: Used to produce threads on shafts and spindles.

- Tapping: Used to create internal threads in holes.

- Rolling: Used to produce threads through plastic deformation, ensuring greater strength and surface finish.

Advantages of Unified Threads

The main advantages of unified threads are:

- Interchangeability: Standardization allows the use of components from different manufacturers.

- Reliability: High precision and mechanical strength.

- Versatility: Wide range of industrial applications.

Conclusion

Unified threads represent an effective solution for industries requiring high-quality and precise components. Thanks to their standardization, companies can achieve significant savings in production and maintenance costs. The adoption of unified threads facilitates international collaboration, allowing the acquisition of components from different suppliers without compatibility concerns.

Furthermore, the reliability and versatility of unified threads make them an ideal choice for critical sectors such as aerospace, automotive, and mechanical engineering. Investing in components with unified threads ensures durability and high performance, providing end customers with superior-quality products..