Kanban Next Box

Kanban with empty-to-full system

Replenishment system with visual control of the items

Traditional Kanban: simplicity and efficiency

Next Box is a traditional Kanban system that features containers of fasteners identified and managed directly at the customer's premises. When one container is empty, the second is immediately available for use. The empty container (and the item inside) is identified, collected, replenished, and returned. A simple, precise, and just-in-time solution.

Management based on real consumption

Once the contents of the first of the two containers are finished, the customer simply needs to communicate the code on the label to communicate the replenishment order and place the empty container in a pre-established space for collection.

What makes Kanban Next Box stand out?

The Kanban Next Box is designed for immediate start-up, the system works even without the implementation of PDAs or smartphones.

In the most advanced version, the K-Box, the code is read via a barcode or QR code reader, which is more convenient and faster.

Main features of Next Box:

Visual inspection

Double container

Reordering missing items

Pickup, delivery and refill service

The advantages of Next Box

Quick and easy implementation

Quickly start-up, the system does not require complex infrastructure and allows for a rapid start-up with minimal initial automation.

Flexibility for non-standard items

Also perfect for customized or non-standard products, with guaranteed traceability and management even in the presence of fluctuating demand.

Guaranteed business continuity

Thanks to intelligent replenishment and constant supervision, the risk of line interruptions is reduced, ensuring continuity in production processes.

What is Kanban?

Kanban is a visual inventory management system that revolutionizes the way you manage your fasteners. It's not just a simple container, but a "pull" methodology that ensures every screw, bolt, or washer is available exactly when needed, preventing backlogs or out-of-stocks.

Find out how to always have the right fastener, at the right time, for seamless logistics!

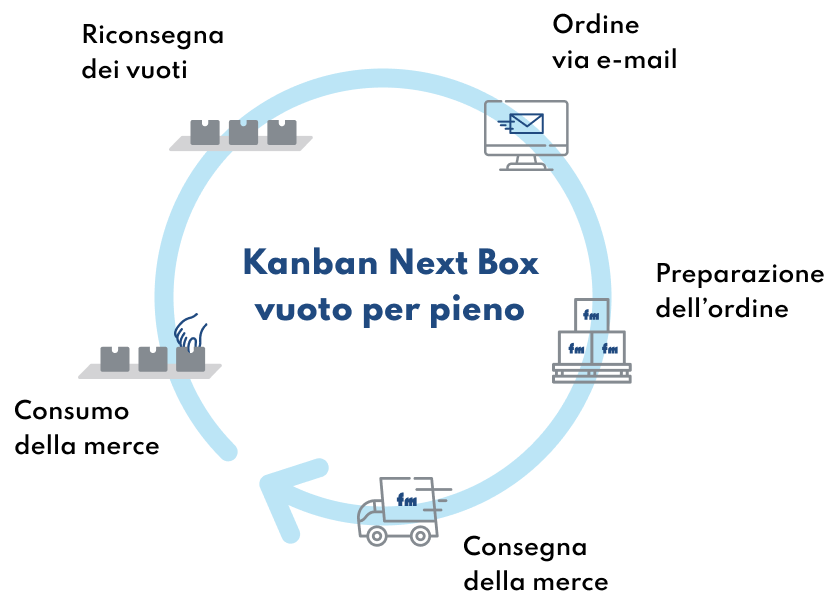

The Next Box operating process

This is the “classic” Kanban solution that involves the management of plastic containers at the customer's operational headquarters.

How does it work?

Next Box on loan for useThe customer's premises are equipped, on a loan for use basis, with plastic containers and labels with the codes needed to identify the item.

Scanning the codeWhen the first box is empty, simply identify the item code, communicate the replenishment order (by email or in the agreed manner) and place it in the collection area.

Return of empty boxesOnce we receive the empty boxes at our offices, we will replace the material and ship it to you.

Discover other Kanban systems

K-Box

A traditional system that involves identified containers, managed directly at the customer's premises. When one is empty, the second is immediately available. The empty container is then collected, refilled, and returned. A simple, precise, and just-in-time solution.

Clever Box

The most advanced solution, with containers equipped with weight sensors and integrated scales. The system records consumption in real time and automatically generates orders. It is customizable, even for non-standard items, and drastically reduces time, errors, and costs.

Arrange a meeting or call

Need more information? Our team is at your complete disposal to provide you with further information, answer any questions you may have, and configure the system that best suits your needs.

Fill out the form and choose how you'd like to meet with us: a phone consultation, a meeting at your office, a meeting at our office for a demo, or simply request a call.

We will show you the solutions and useful steps, without obligation.

Don't want to fill out the contact form?

Call us or send us an e-mail!

39 0522 271117

commerciale@fmspa.com