HOT FORGING: TECHNICAL ANALYSIS AND APPLICATIONS

Introduction

Hot forging is a widely used metalworking technique in the mechanical industry for producing components with complex geometries and high mechanical properties. This process involves heating the material above its recrystallization temperature, allowing the metal to deform plastically without breaking. Hot forging is particularly suitable for manufacturing large and high-strength parts used in critical sectors such as the automotive, aerospace, and heavy machinery industries.

Hot Forging Process

The hot forging process consists of several stages, each essential to ensuring the quality and mechanical properties of the final product. Below is the typical sequence of this process:

1. Material Heating

- Description: The raw material (usually a bar or ingot of metal) is heated in a furnace until it reaches a temperature above the recrystallization point, which for steel ranges between 1100-1250°C.

- Applications: This heating makes the metal more malleable, facilitating deformation during the forging phase.

2. Forging

- Description: The heated material is placed in a mold, where it undergoes plastic deformation to assume the desired shape. This process occurs under the action of powerful hydraulic or mechanical presses that can exert high pressures.

- Applications: Ideal for producing complex structural components such as shafts, gears, and automotive frame parts.

3. Cooling and Heat Treatments

- Description: After forging, the piece is cooled, often rapidly, to induce specific mechanical properties, such as increased hardness or strength. In some cases, additional heat treatments such as quenching and tempering are required to optimize material properties.

- Applications: Used to enhance the mechanical characteristics of components, adapting them to specific application requirements.

4. Finishing

- Description: After cooling, the part may undergo finishing operations such as grinding, sandblasting, or machining to achieve the desired dimensional tolerances and surface finish.

- Applications: Necessary to ensure that the component meets the required dimensional and quality specifications.

Hot Forging Process Characteristics Table

| Phase | Description | Objective |

|---|---|---|

| Material Heating | Bringing the material to deformation temperature | Increase metal malleability |

| Forging | Plastic deformation of the material in the mold | Obtain the desired shape |

| Cooling and Heat Treatments | Controlled cooling of the piece and additional treatments | Optimize mechanical properties |

| Finishing | Refinishing operations to meet specifications | Ensure surface and dimensional quality |

Hot Forging Applications

Hot forging is used in a wide range of industrial sectors, especially where high mechanical properties and complex geometries are required. Some examples include:

1. Automotive Industry

- Example: Production of structural components such as connecting rods, crankshafts, and gears. These components must withstand high loads and extreme operating conditions.

- Advantages: Offers high mechanical strength and durability, essential for ensuring vehicle safety and reliability.

2. Aerospace Sector

- Example: Manufacturing of jet engine parts, such as turbines and compressors, which must endure high temperatures and pressures during operation.

- Advantages: Ensures high-precision and high-strength components necessary for safe and efficient operations in critical environments.

3. Heavy Machinery Construction

- Example: Production of agricultural tools, excavator and crane components, which require wear and impact resistance.

- Advantages: Provides robust components that can withstand heavy loads and prolonged wear, increasing machine longevity.

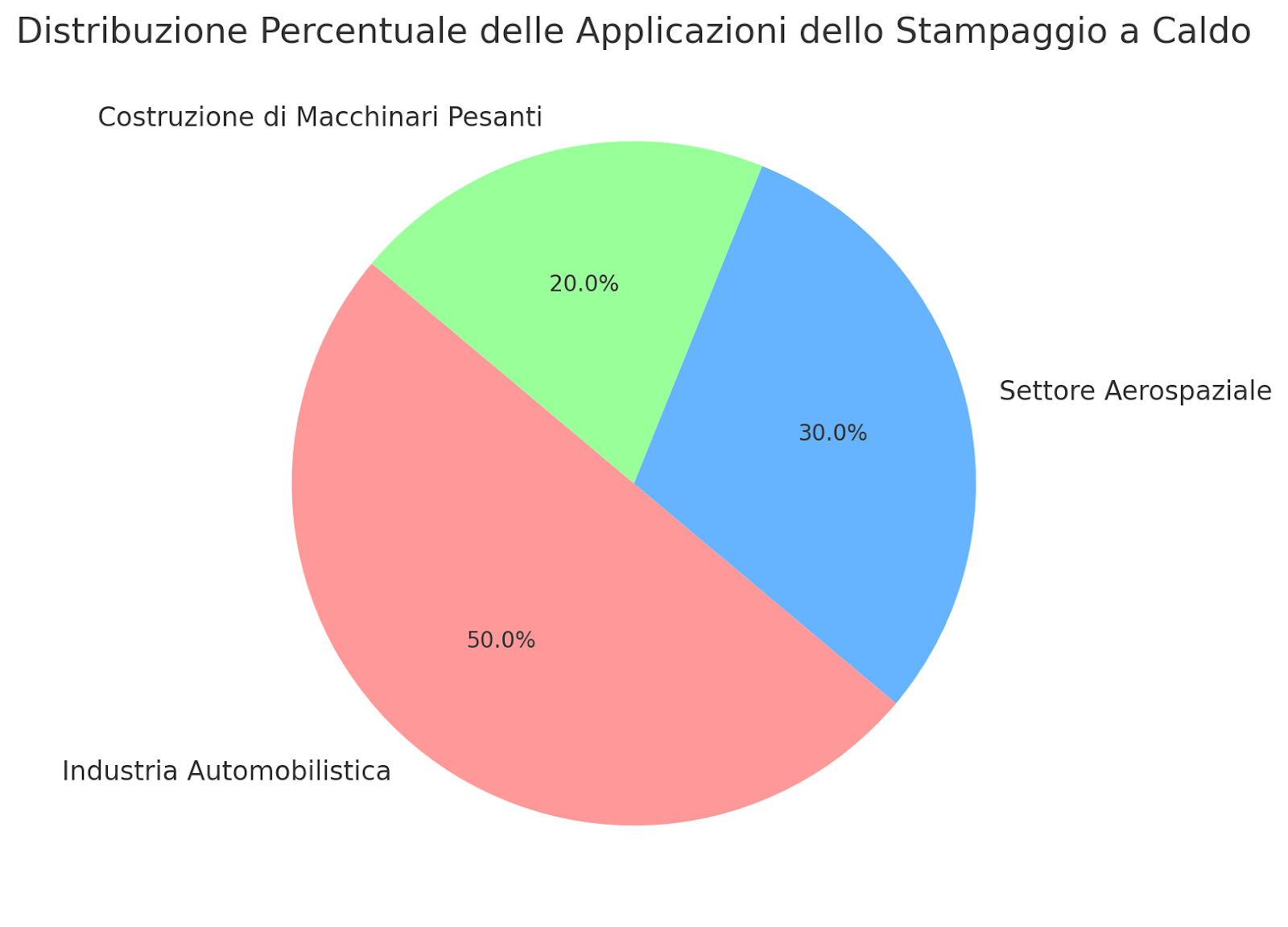

Graph: Distribution of Hot Forging Applications

Below is a graph showing the percentage distribution of common applications for hot forging:

This graph highlights how hot forging is widely used in the automotive, aerospace, and heavy machinery industries, where mechanical strength and precision are essential.

Advantages and Challenges of Hot Forging

Advantages:

- High Mechanical Strength: The process allows for the production of components with superior mechanical strength compared to other manufacturing methods.

- Complex Shape Capabilities: Hot forging enables the production of complex geometries that would be difficult or impossible to achieve with other methods.

- Material Property Enhancement: Heating and subsequent heat treatments can improve material properties such as hardness and wear resistance.

Challenges:

- Tooling Costs: The process requires specialized and expensive equipment, such as high-capacity molds and presses.

- Dimensional Tolerance Control: Maintaining tight tolerances can be challenging, requiring subsequent finishing operations.

- Thermal Management: Temperature control during the process is critical and can significantly impact the final product quality.

Commercial Conclusion

Hot forging is a fundamental technology for producing high-performance mechanical components. Although it involves high tooling costs and requires precise thermal management, its advantages in terms of mechanical strength, ability to produce complex shapes, and improvement of material properties make it a preferred choice for high-criticality sectors.