STAMPING

The stamping process for the production of screws and bolts is fundamental in the mechanical industry. It enables the creation of essential components for assembling structures and machinery. Stamping ensures precision, strength, and durability—essential characteristics for screws and bolts.

Stamping Processes

Cold Stamping

Cold stamping is a process that involves plastic deformation of the metal without heating it. This method is mainly used for small and medium-sized screws and bolts.

Advantages

- High dimensional accuracy

- Smooth surface finish

- Improved mechanical strength due to work hardening

Disadvantages

- Limited to materials with good ductility

- Higher die wear

Hot Stamping

Hot stamping involves heating the metal before deformation. This process is used for producing large bolts and for materials that cannot be easily cold-worked.

Advantages

- Easier deformation

- Suitable for hard and brittle materials

- Ability to produce large components

Disadvantages

- Lower dimensional accuracy

- Requires additional processing to improve surface finish

Finishing Processes

After stamping, components may undergo finishing treatments such as galvanization, painting, and tempering to enhance corrosion resistance and mechanical properties.

Material Properties

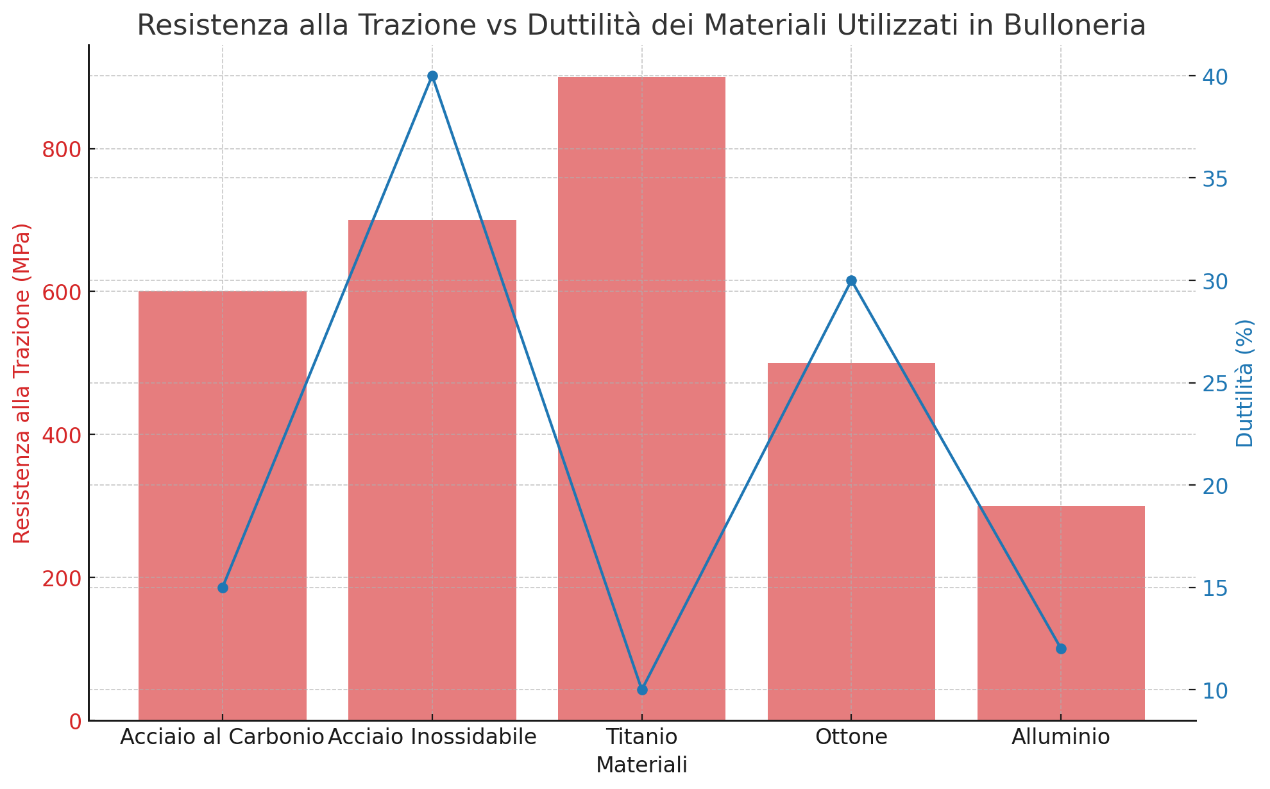

| Material | Hardness (HV) | Tensile Strength (MPa) | Ductility (%) | Typical Applications |

|---|---|---|---|---|

| Carbon Steel | 150-250 | 600-900 | 10-20 | Screws, bolts, nuts |

| Stainless Steel | 200-350 | 500-800 | 20-30 | Marine, food industry applications |

| Titanium Alloys | 300-400 | 900-1200 | 15-25 | Aerospace, automotive |

Graph: Tensile Strength vs Ductility

The graph above shows the relationship between tensile strength and ductility for different materials used in the production of screws and bolts.

Stamping Process Images

The following image illustrates the stages of the cold stamping process:

Applications of Screws and Bolts

Screws and bolts are used in various industries, including:

- Construction: Used for assembling structures and scaffolding.

- Automotive: Used for assembling engine parts and body components.

- Aerospace: Used for structural components and fastening systems.

Conclusion

Investing in advanced stamping processes for the production of screws and bolts offers numerous advantages to companies. The precision and strength of components produced through these processes ensure reliability and safety in final applications. Partnering with specialized suppliers and using high-quality materials can significantly reduce maintenance costs and improve product performance.